right size and shape. Each of the cones required cutting the top

and bottom out to get the right 1” diameter at the top and cor-

rect 3/8” diameter at the tank bottom.

Once I had cut the cones to shape, I used ACC to glue the

cones to the PVC silos. The resulting seams weren’t perfect, so

I applied several coats of Bondo body putty to fill the seams.

Were I to do the silos over, I would have approached the con-

struction slightly differently by wrapping the styrene first, with

a slight overlap at the bottom of the PVC pipe, and glued the

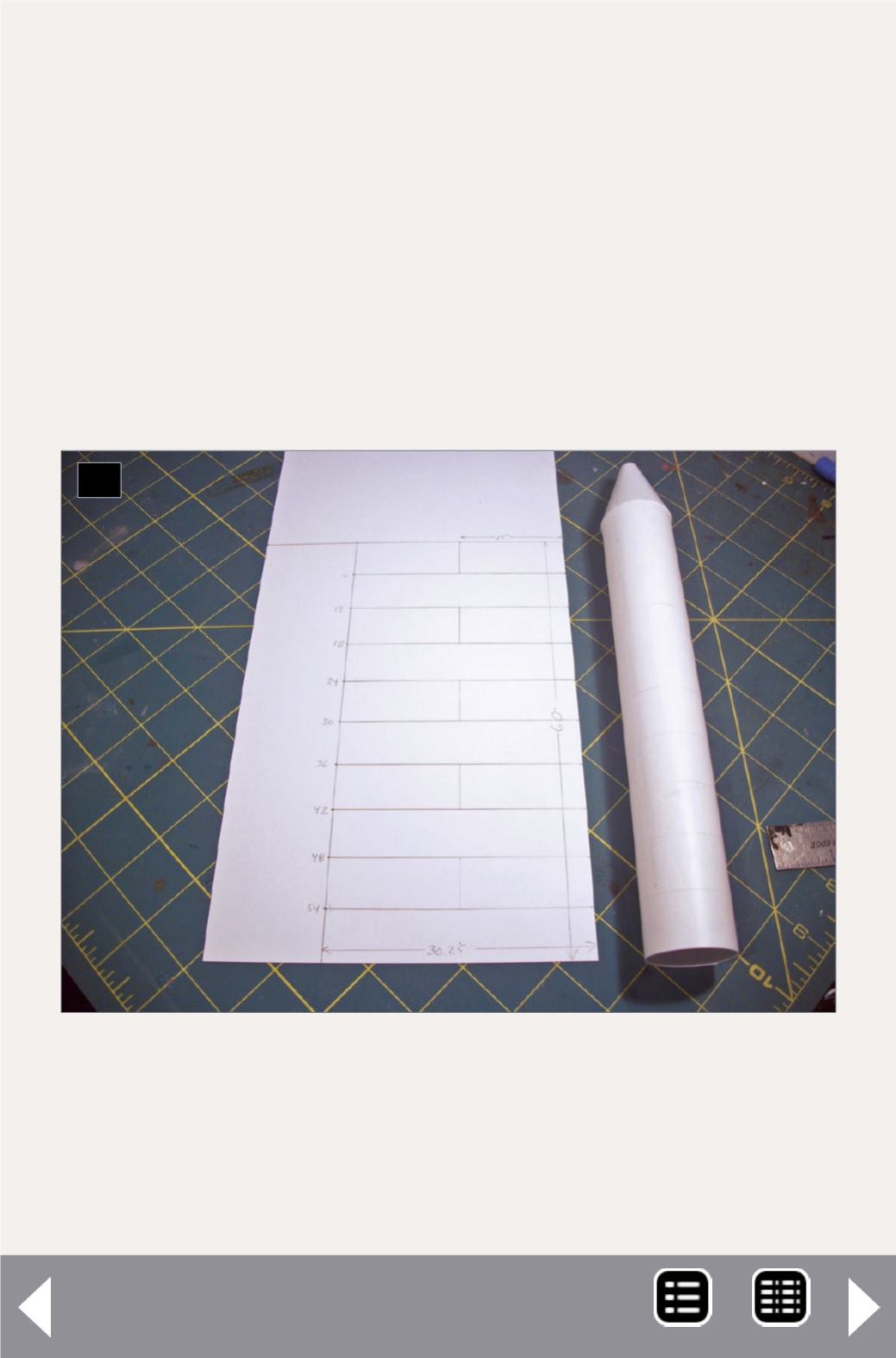

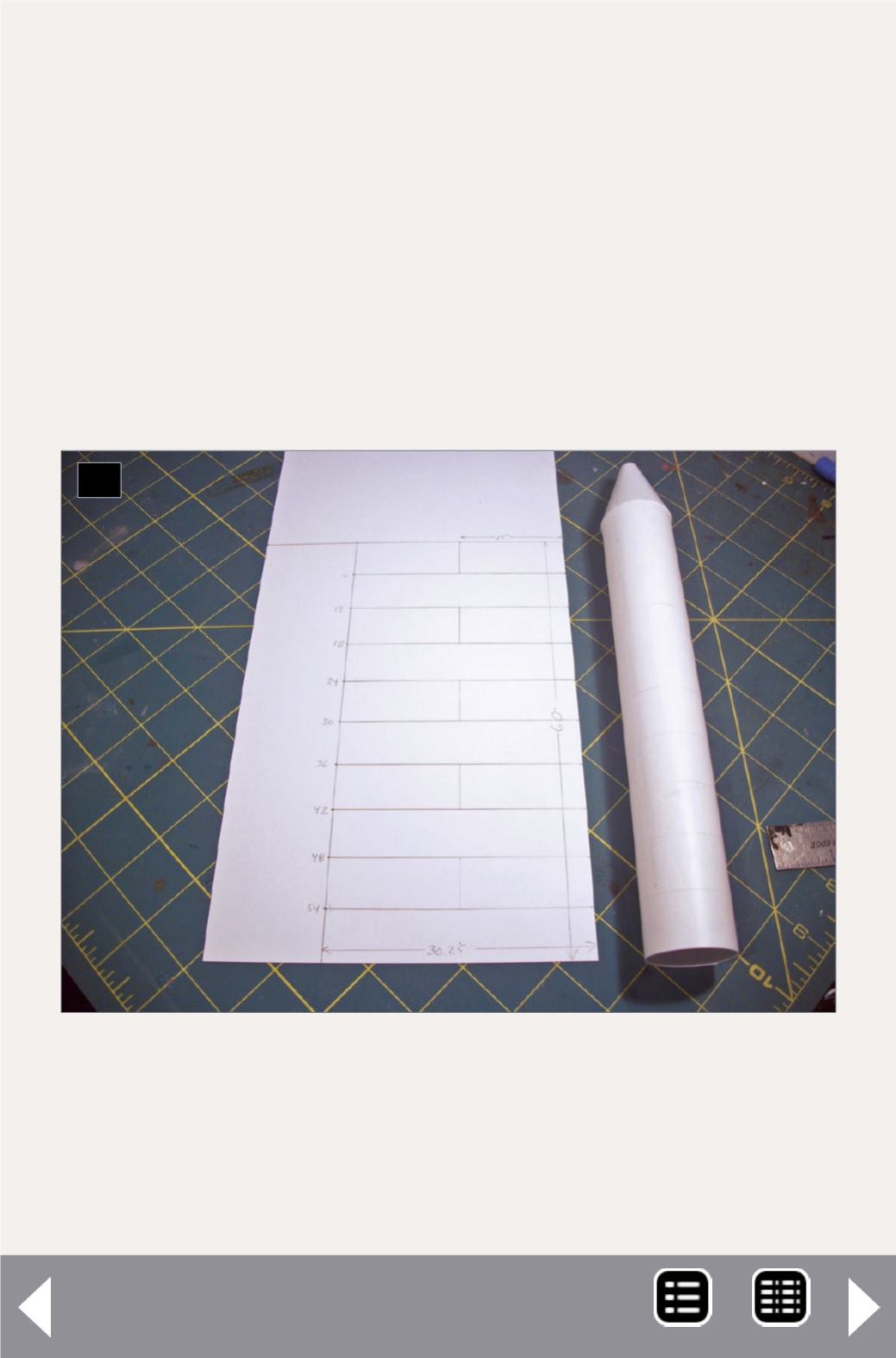

21. This photos shows preparation of the .010” styrene

sheet to be wrapped around the PVC silo. The overall

size of the sheet is 60 scale feet tall by 30.25 scale feet

wide. Gently scribed lines every 6 scale feet represents

the weld seams of the silo.

21