7

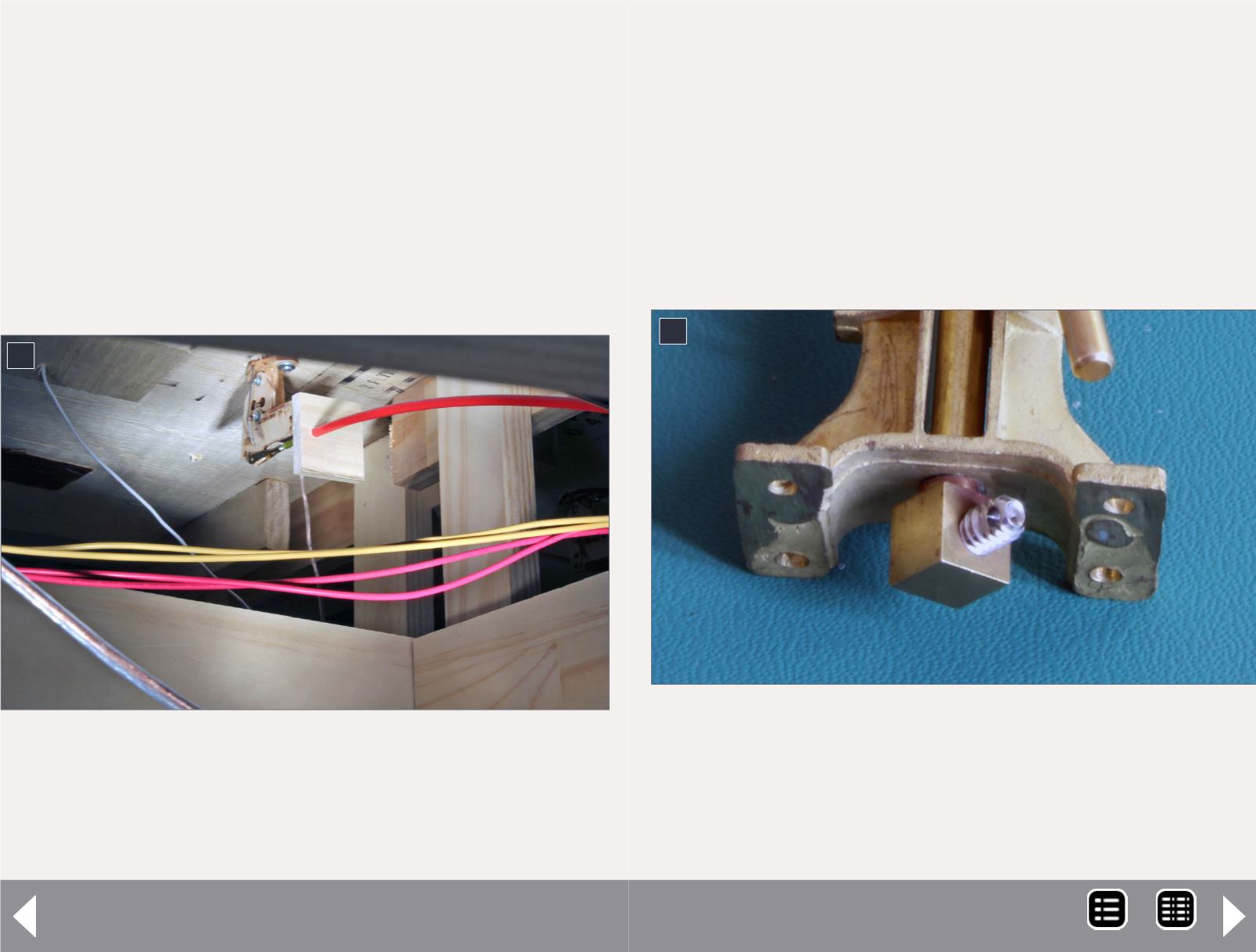

7. At the other end of the plastic control rod, a

BullFrog manual switch machine moves the points.

The BullFrog has been fitted with a larger wooden face

to support the control rod, since the use of clevises

required moving the position of the rod.

Realistic switch control - 4

Cut the extension from 3/8” diameter brass tube. Length will

vary depending on the shelf used, but it needs to be long

enough to connect to the bottom of the stand and extend

about an inch below the shelf.

Cut a collar for this extension from 7/16” brass tube. The

length will be the same as the depth of the shelf. Clean up the

cut ends to make sure the 3/8” brass tube slides smoothly

through this collar.

Solder a 1” length of brass bar stock (see Bill of Materials) to

the bottom of the extension tube creating a lever. Drill a couple

of holes in the lever to provide some choices for connecting

the control rod.

The final step is to cross-drill the extension tube to secure it to

the bottom of the stand with a machine screw, so the exten-

sion will rotate when the stand is operated. The machine screw

replaces the threaded rod that comes with the switch stand, so

use the threaded rod to determine what size screw to use.

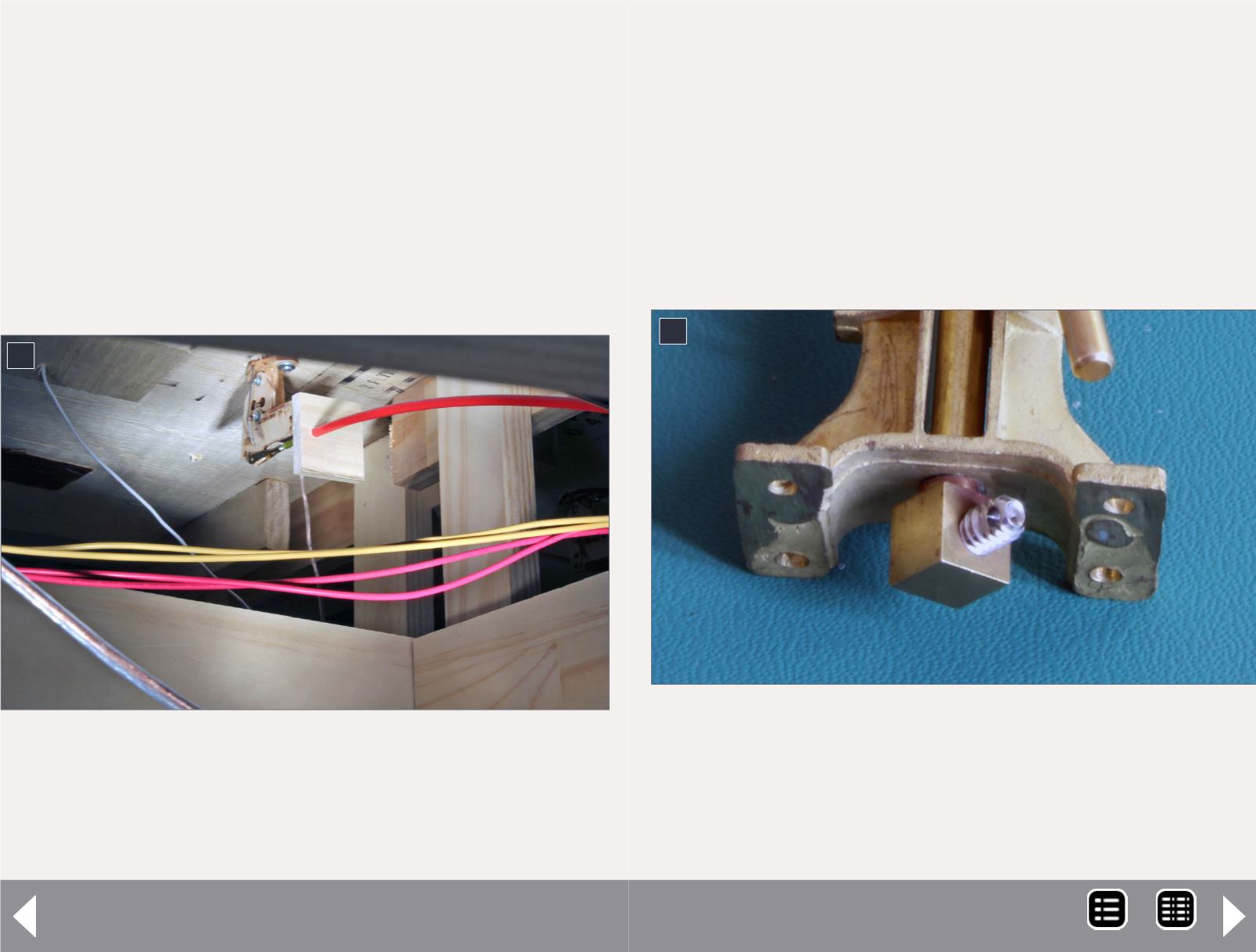

8. Here’s a closeup of the stock switch stand from

Sunset Valley Railroad. As designed. the brass cube at

the bottom of the stand is drilled to accept a threaded

rod. This will be replaced with a screw to secure a

brass tube to the cube and create the extension lever

required for use on the layout.

8

MRH-Aug 2014