round of track cleaning. My conjecture is that the oil degrades

after a while and has to be cleaned off and re-applied regularly.

A very simple rail treatment is graphite. Yes, a good old pen-

cil, or better yet, a graphite stick from an art store (cost about

$1.50, I use a 2B Hardness). Clean the rails and rub the graphite

stick along to give a thin coating of graphite over the surface.

Graphite is also an excellent lubricant, so you might have prob-

lems with wheel slippage. If you have steep grades, this might

not be for you!

One year ago, I treated a section of my mainline with graphite.

Just recently, locomotives started stalling on that section and it

required cleaning. I had to clean the rest of the track at least 5

times over that same year, so I would say that the graphite was

pretty successful! For cost and simplicity this is pretty hard to

5

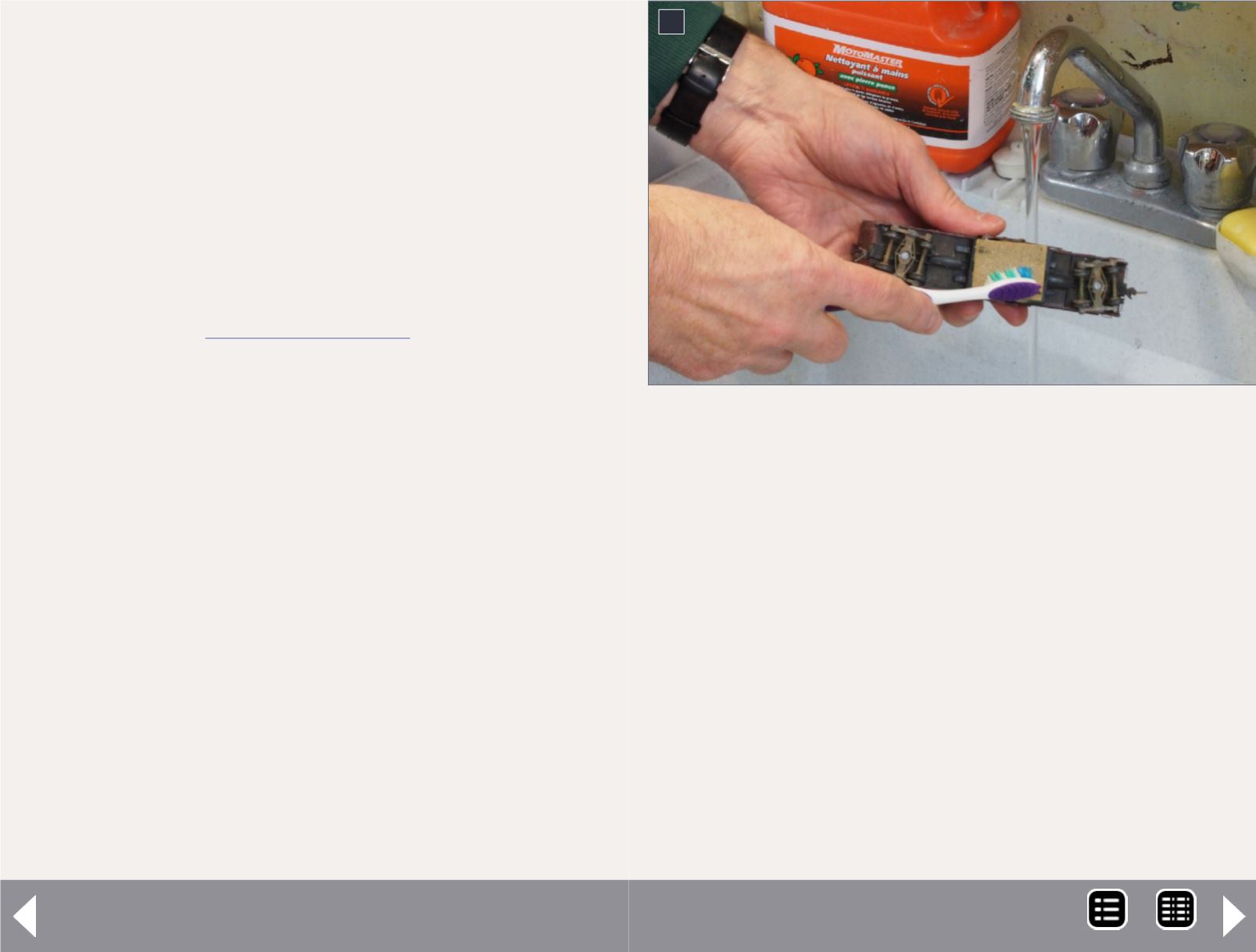

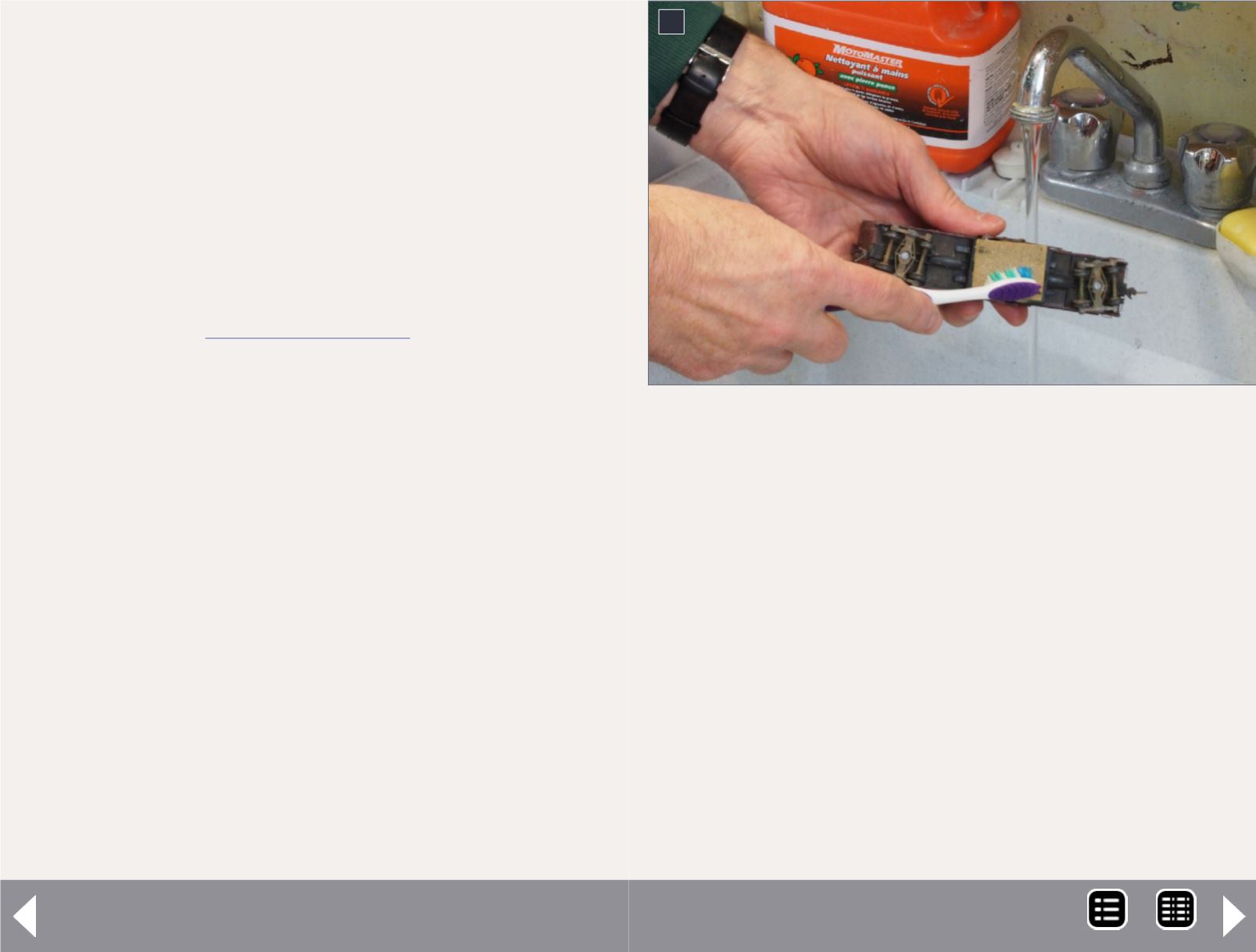

5. The Masonite cleaning sled can be cleaned with a

toothbrush and bar of soap under the sink.

Cleaning the cloth pads can be accomplished in the sink with a

toothbrush and bar of soap. I have a long section of track that

is difficult to access and this is the only way to clean it.

Problem #4: Maintenance. My track is

clean. How do I keep it that way?

The first steps start before you even start laying the track!

Finish the layout room so that dust doesn’t come from the ceil-

ing or from the cement floor.

A simple method of track maintenance is to run Masonite sled

track cleaning cars

every time you run

trains. You will need several of them and change them out fre-

quently as the pad gets dirty fast. The pad can be cleaned with

sandpaper or a toothbrush and bar of soap in the sink.

A number of treatments that can be applied to the rails; I have

tried some of these methods, but there are others such as CRC

2-26, Flitz polish and even “gleaming” that I haven’t tried.

I did try some metal polish used for polishing chrome bits on

cars. It was messy to apply and worked for a couple of months,

but was not particularly effective.

The next treatment I tested is to apply a small amount of a

conductive oil on the rails. This can be Wahl clipper oil or a

product by AeroCar (Act-6006). These products do seem to

improve performance, in my experiences, especially with

sound equipped locomotives. However, the improvement

does not seem to last. I found that after five or six weeks there

would be a rather sudden and drastic failure where locomo-

tives would start stalling in multiple places on the layout, and

I couldn’t keep trains running without going through another

Experiments with track cleaning - 5

MRH-Jul 2014