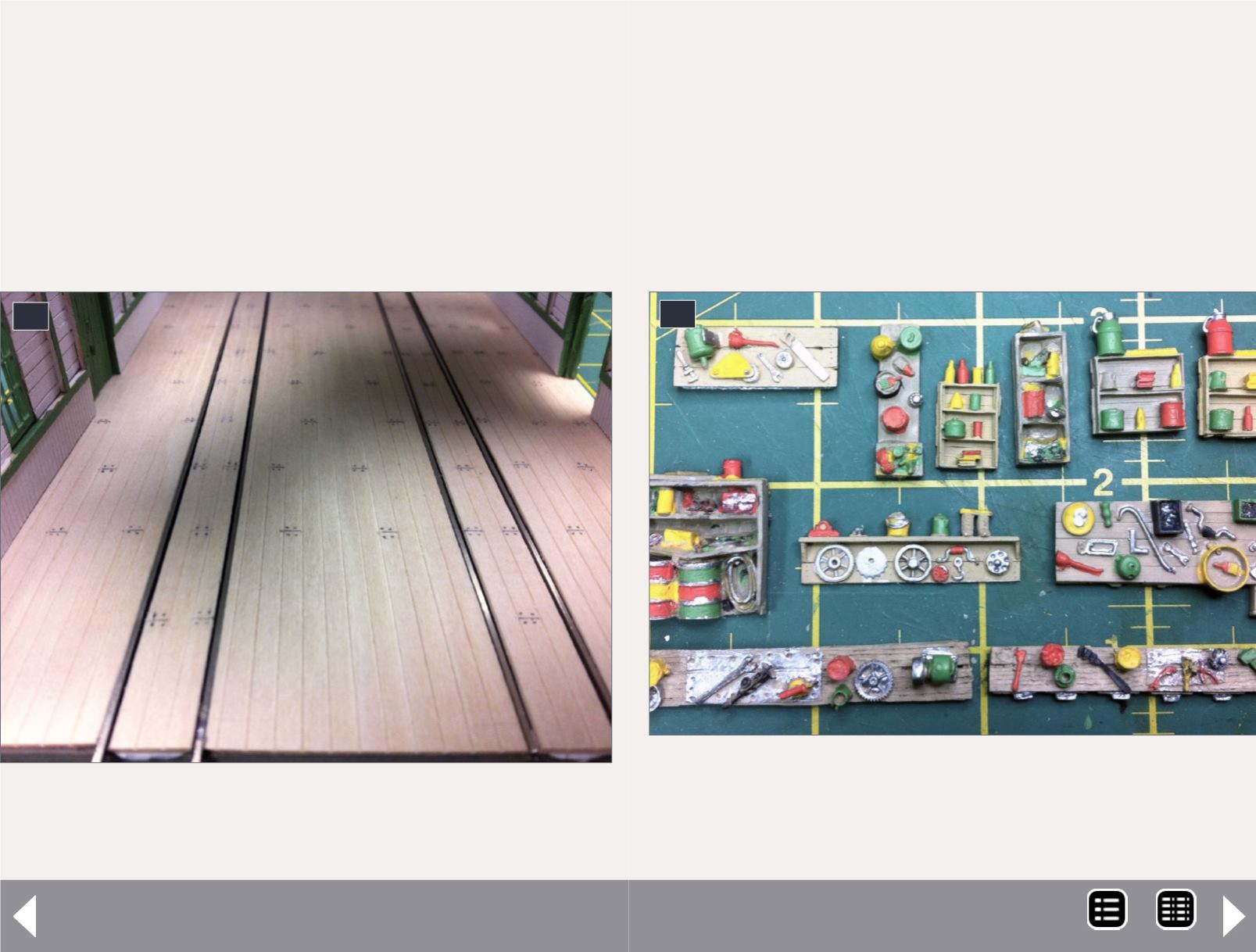

After making sure that all engines fit, and clearances were OK, I

moved some workbenches to a different location and re-tested

the clearances. Then I removed everything to begin marking

the individual board lengths on the flooring, and punching nail

heads into it (a time-consuming job, but worth it to get the end

result). Next I stained the entire floor to give it an aged and

well-worn look. When doing this, I made sure to weight the

for a scribed-sheet floor, since I was not building a diorama

base, and had to figure out how to do the interior without one.

I mounted the scribed siding onto a cardstock base to bring the

floor up to the height of the railhead.

Checking clearances

The next step was to test-fit the workbenches in the building,

to make sure there was enough clearance for the locomotives.

17. I laid out the individual boards and punched nail

heads into them. Now to stain the floor and give it that

well used look.

17

18

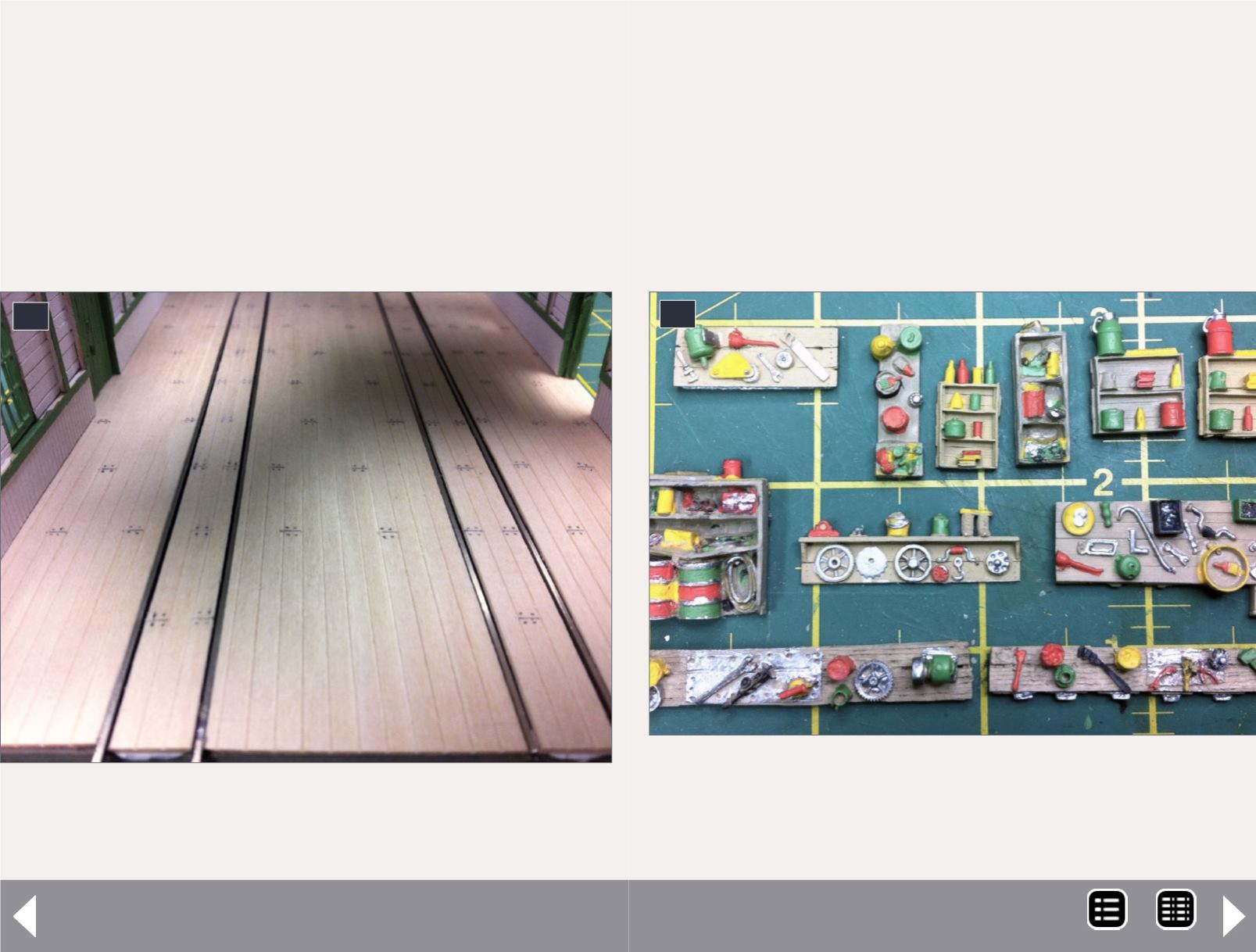

18. Painting all of the details on the castings is a real

time-consuming job. Don’t plan on doing it all in one

sitting. Once the details were glued in place, I gave

them a black wash to get that used, dirty railroad look.

Building a two stall engine house- 9

MRH-Jul 2014