and weight

them mini-

mize warp-

ing. If warping

occurs, brac-

ing on both

interior and

exterior will

correct it.

I laid all the

metal door

and window

castings on

masking tape,

sticky side up,

for spraying

with an air-

brush (quicker

than painting

with a brush.

I use my air-

brush only if

there are a

lot of parts to

be sprayed).

Once thor-

oughly

dry, turned them over and sprayed the unpainted side.

Airbrushing speeds up the drying time to minutes, and a

smoother finish is obtained. I then started with the exterior

and interior bracing.

Modifications to the kit

The instructions call for a stone foundation along the bottom

of the engine house. I deviated from this, and added scribed

siding vertically to keep the whole structure wood. This is a

personal preference, but makes it easier to add the work-

benches and details flush with the walls on both the exterior

and the interior.

After bracing the track doorways, I tackled the main doors.

Here the instructions say to use the cut individual stripwood

supplied to make up the doors. Instead I used thin scribed sid-

ing affixed back-to-back with double-sided tape to give the

inside and outside the individual-board look. It worked very

well. I marked the scribed siding, using the side walls with the

5

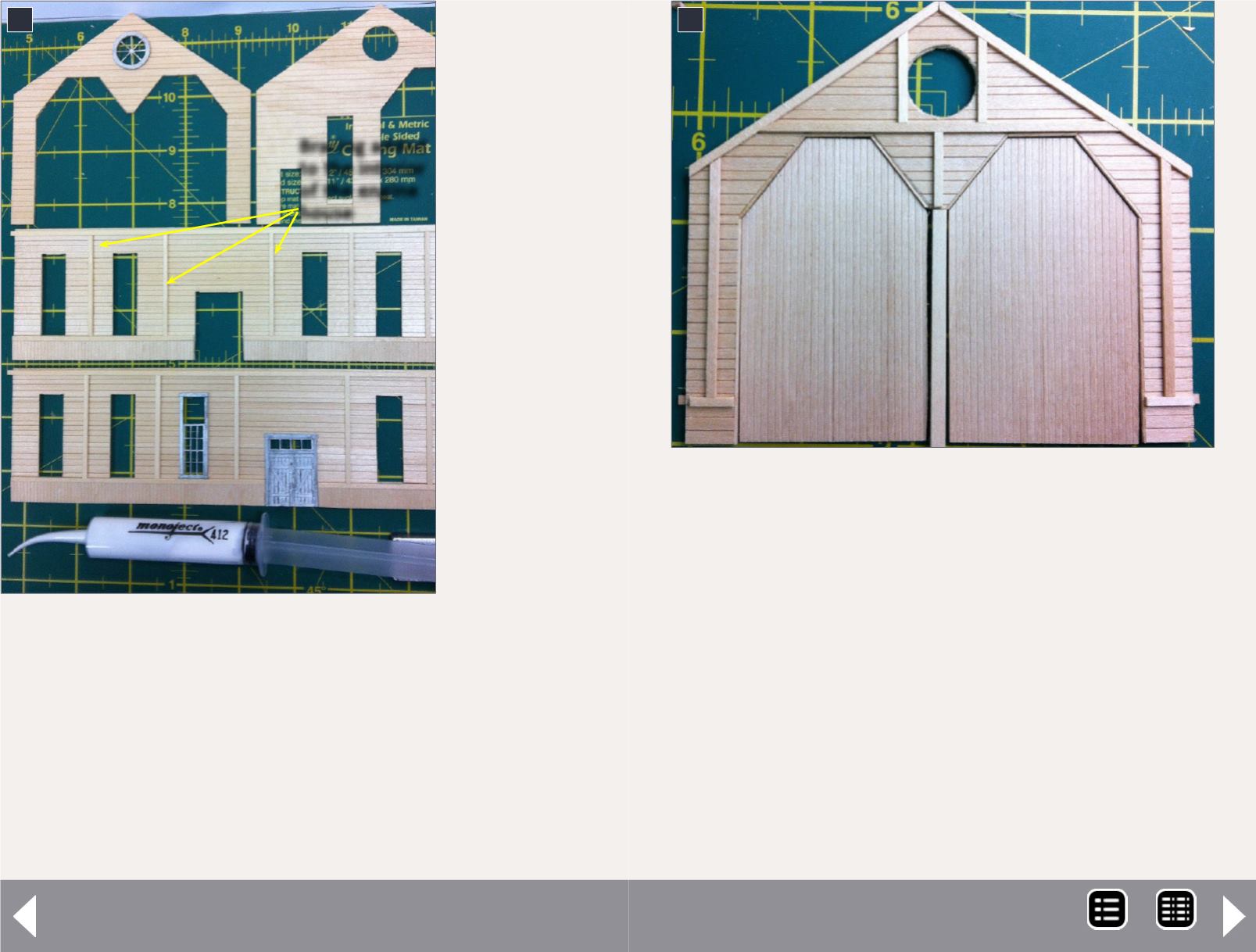

5. Bracing adds both interior detail and

strengthens the structure.

Bracing added

to the interior

of the engine

house

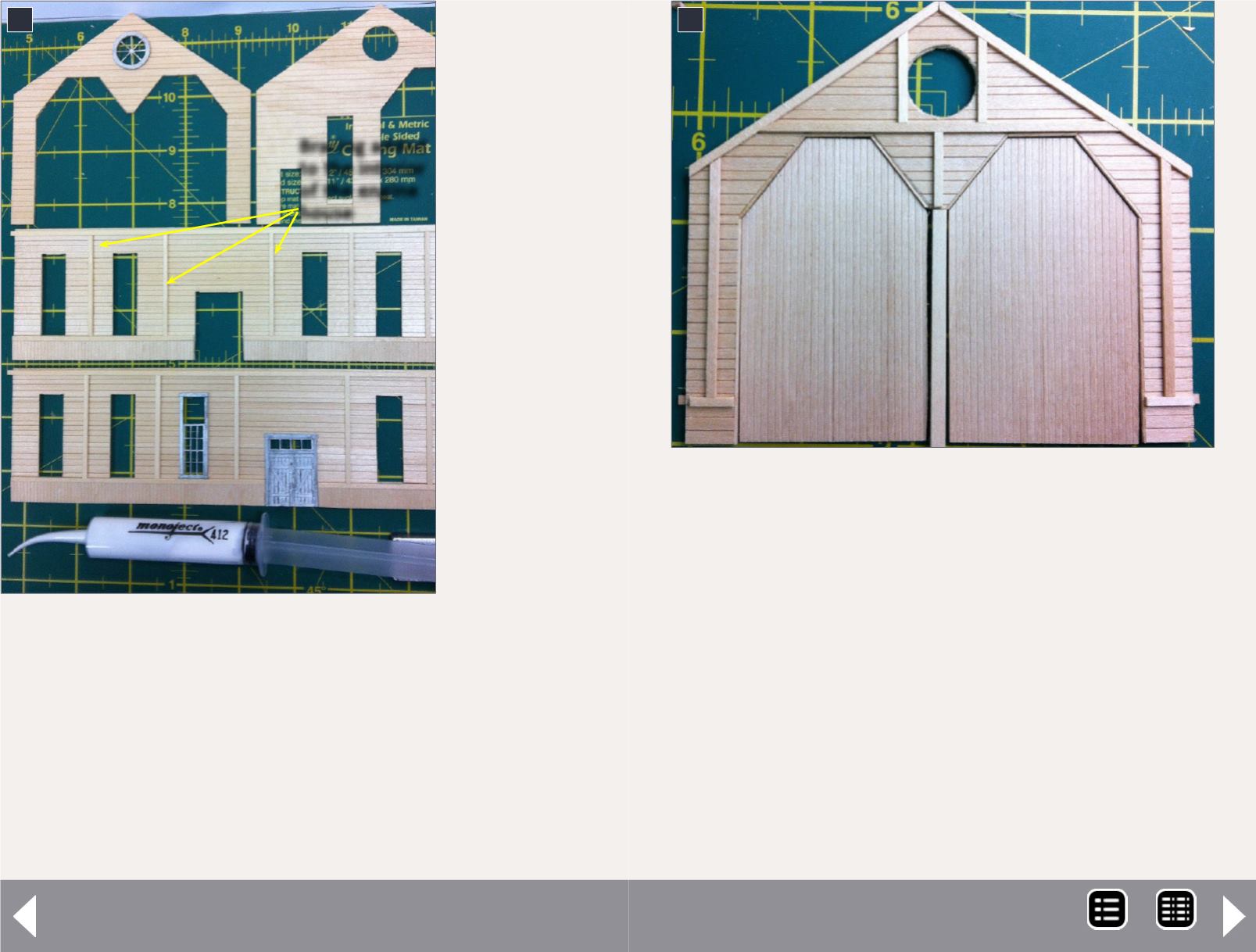

6. This picture shows the details of the interior bracing

of the front doors of the engine house.

6

Building a two stall engine house- 4

MRH-Jul 2014