and industry (the runaround siding wasn’t visible from the

street view).

After a week of on-and-off Internet searching, I had gath-

ered enough information to start choosing what to model. I

know the shortline primarily serves the lumber industry. It

also serves a wood pellet manufacturer, steel beam fabrica-

tor, juice-based beverage manufacturer, animal feed and seeds

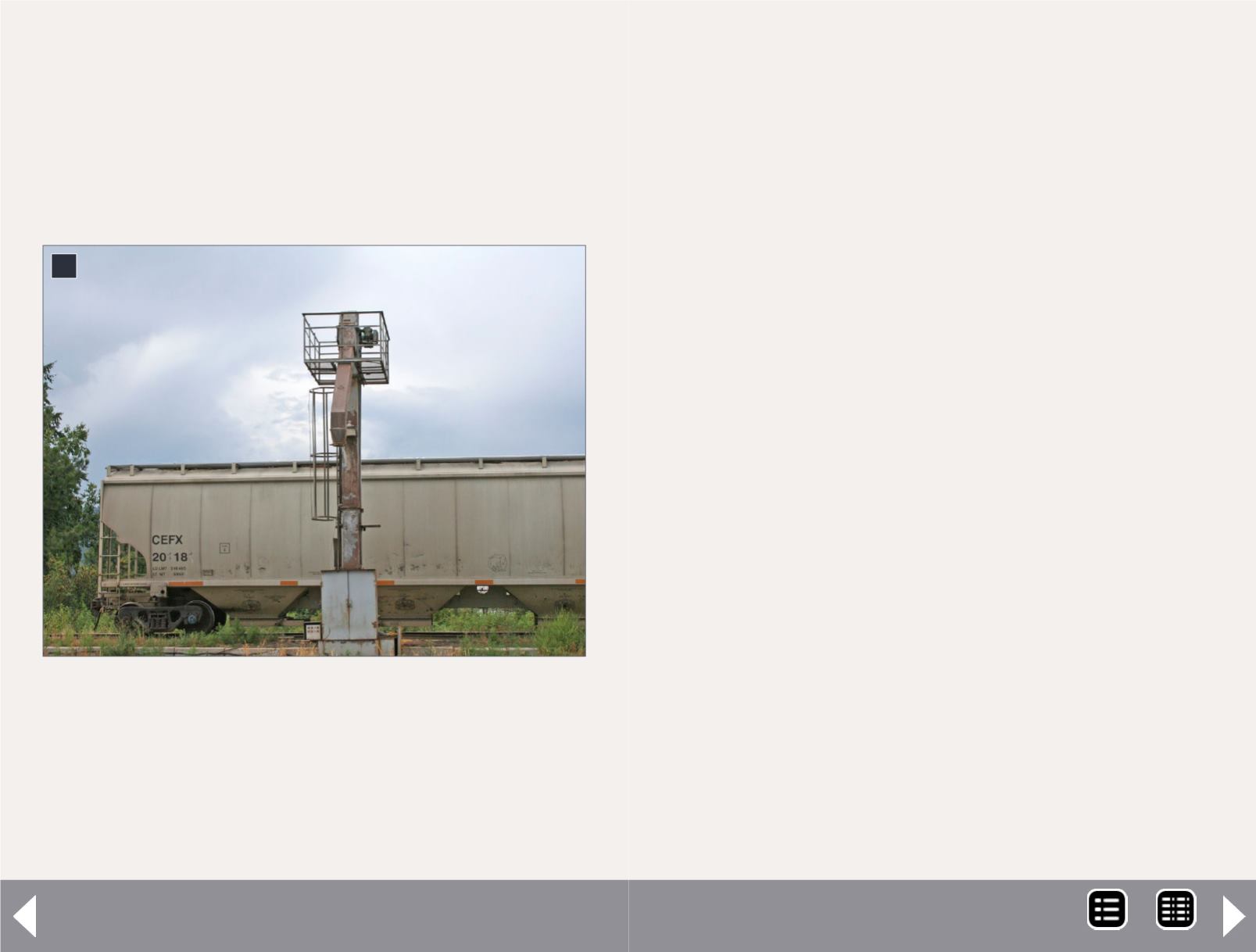

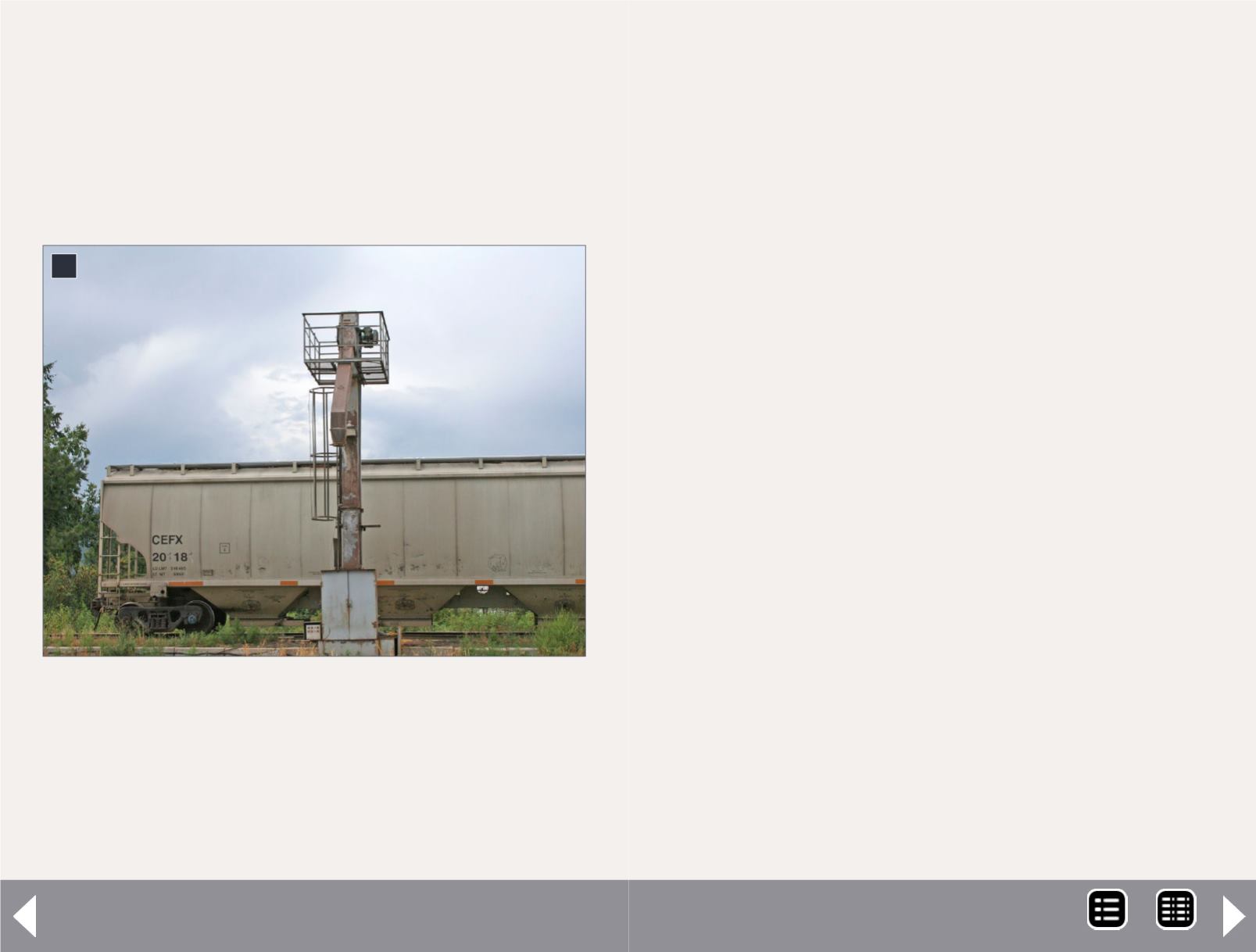

3. The budget will limit the structures used to model

industries for now. However, this covered hopper

unloading location does not require any buildings. To

the left of this photo the track ends in front of the steel

beam fabricator; 11 60’ car-lengths to the right is the

dirt ramp for a corrugated pipe manufacturer, and the

beginning of the siding.

3

$500 layout 1st place - 3

distributors, flour mill, chemical distributor, scrap metal yards,

cement distributor, oil distributor, propane distributor, and a

transloading terminal.

The railroad primarily uses leased GP38-2 diesels. It once had a

leased SW1500 (Conrail logo still visible).

Satellite images may capture freight cars in the siding, and pro-

vide a clue about the length of the siding and type of freight

cars used. As a bonus, Google Street View may capture freight

cars at an industry or siding, and if you are fortunate, as I was,

an engine crew switching an industry.

To help with modeling the railroad and designing the track

plan, take as many screen shots and notes as possible.

Design

Let’s start the initial design phase by defining requirements of

the model railroad, keeping in mind the reality of the budget

and space.

The design goals are:

Point-to-point operation

Modular design

Easily expandable

Easily transportable

Industrial switching

Freight yard

One engine (GP38-2, hopefully)

Modern freight cars

Avoid compression

Operational challenge

MRH-Jun 2014