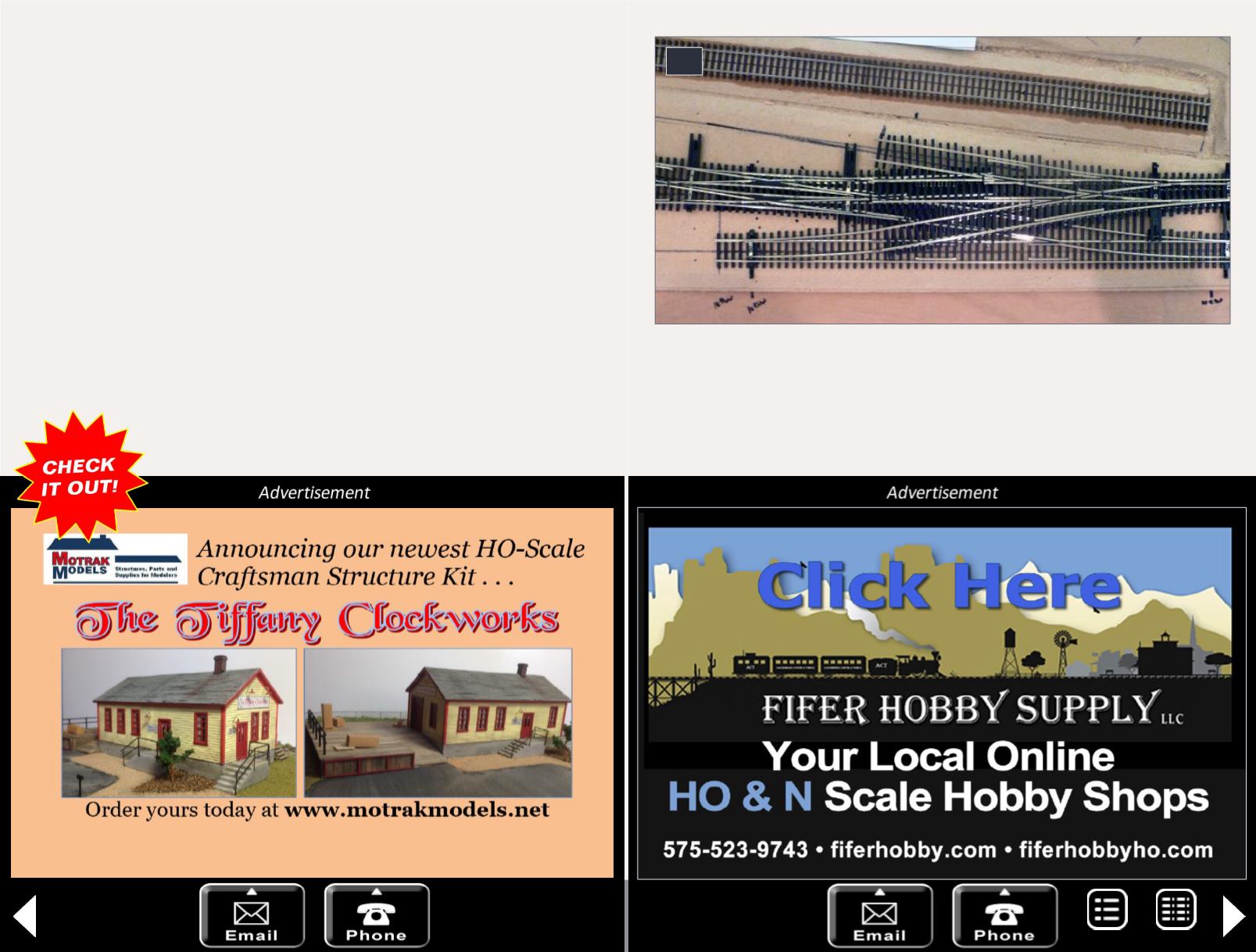

Using these techniques, I continued laying rail southward from

Noel, Missouri. This eventually brought me down to the lower

end of the layout, and the time to lay the complex track work

for the south throat of the Deremus freight yard. On model

railroads, complex track work such as this allows us to selec-

tively compress a lot of operating into a small space. In addi-

tion, the switch work enhances the prototypical appearance

and impresses visitors!

It’s been over 10 years since I constructed track like this for the

Kansas City Terminal Railway, so was a matter of refreshing my

skills. The first step was to lay the switches in position over the

tracks’ centerlines. This gave me a general idea of what kind of

cutting and fitting would be required [17]. Given the cost of a

double-slip switch or three-way switch, cutting the switches to fit

must go right the first time! To ensure this, I photo-

copied the switches and then cut and fit the paper

17. The switches temporarily laid in place.

17

templates. This allowed me to know exactly where the actual

switches should be cut. This junction required one double-slip

turnout, one double-crossover and one three-way turnout [18].

MRH-May 2014