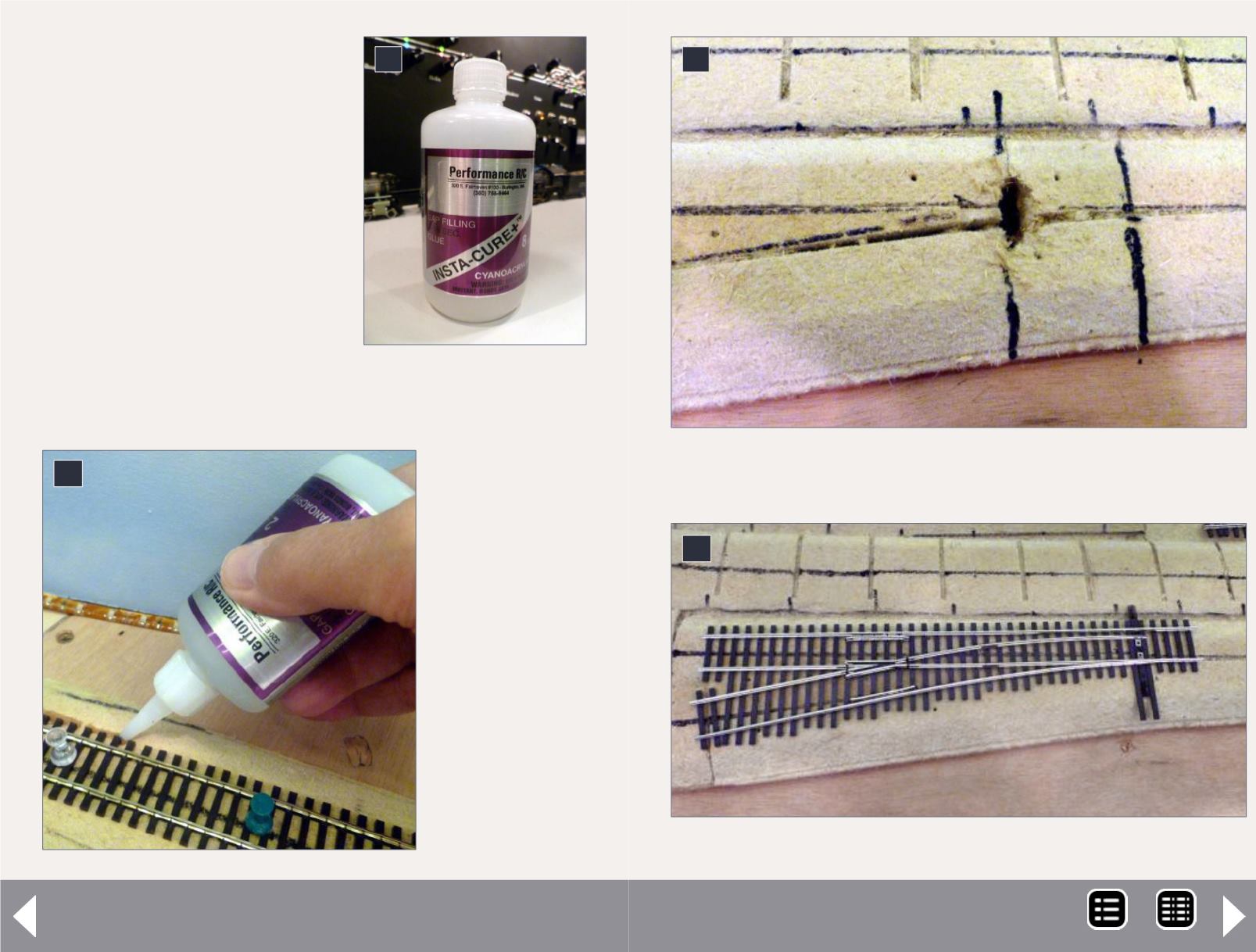

Getting Real Column - 3

layout, I fixed the track in place by

using gap-filling cyanoacrylate. I ran

a bead of ACC along each edge of

the ties. When the glue has set, the

pushpins can be removed. A word of

caution – as the glue cures, a white

haze can form on anything near the

track, so keep the area around the

track clear for 24 hours [3-4].

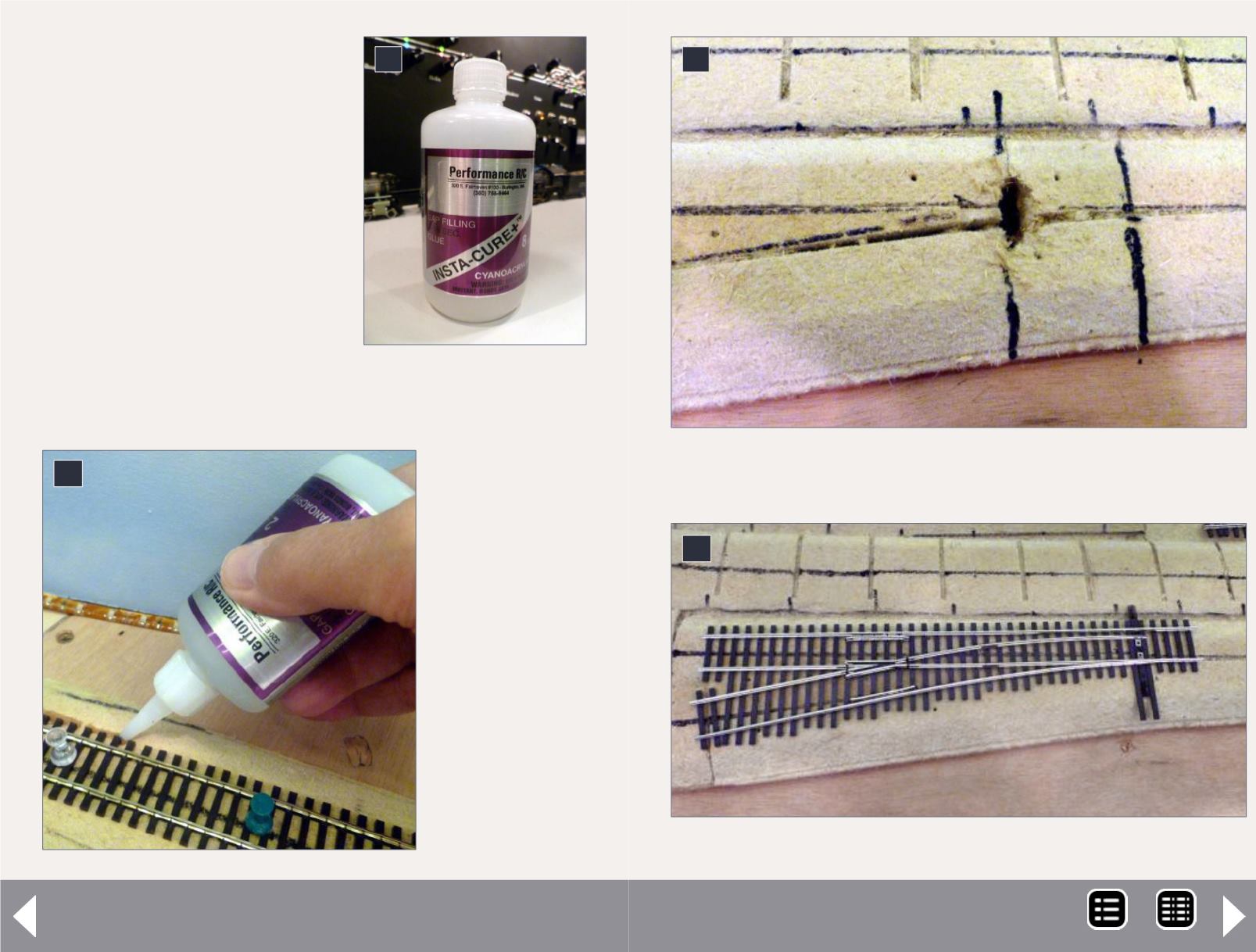

For the turnouts, it’s necessary

to accurately locate the position

of the throwbar to drill a hole

through the layout for the actuat-

ing wire from a Tortoise switch

machine. Once the position was marked, I drilled an elongated

hole, moving the drill from side to side with a sharp ¼” bit.

Especially in

curves, and at

other locations,

you will find that

the rail ends

don’t match;

one will be lon-

ger than the

other. In this sit-

uation, I lay the

3. Gap filling

ACC glue.

4: Run a bead

of ACC along

each end of

the ties.

3

4

5. Marking the throw rod position.

5

6. Drilling a slot for the throw rod.

6

MRH-May 2014