Getting Real Column - 2

An exception to this was a package of Peco flex track I pur-

chased from my local hobby shop. The Micro-Engineering track

is held quite firmly by the ties, which makes bending smooth

curves a challenge. On the contrary, the Peco track flexes very

easily. The spikes are a little on the large side, and only four per

tie, but ease of handling makes the difference. I used the Peco

track to lay the four parallel curved tracks in the Deremus yard.

In the past, I laid the track using spikes about 2” apart, as

needed to hold the track in alignment. Unfortunately, (or fortu-

nately!), the Celotex sub-roadbed does not hold the tiny spikes

nearly as well as Homasote. That led me to find a better and

faster way to hold the track in alignment. I laid the track over

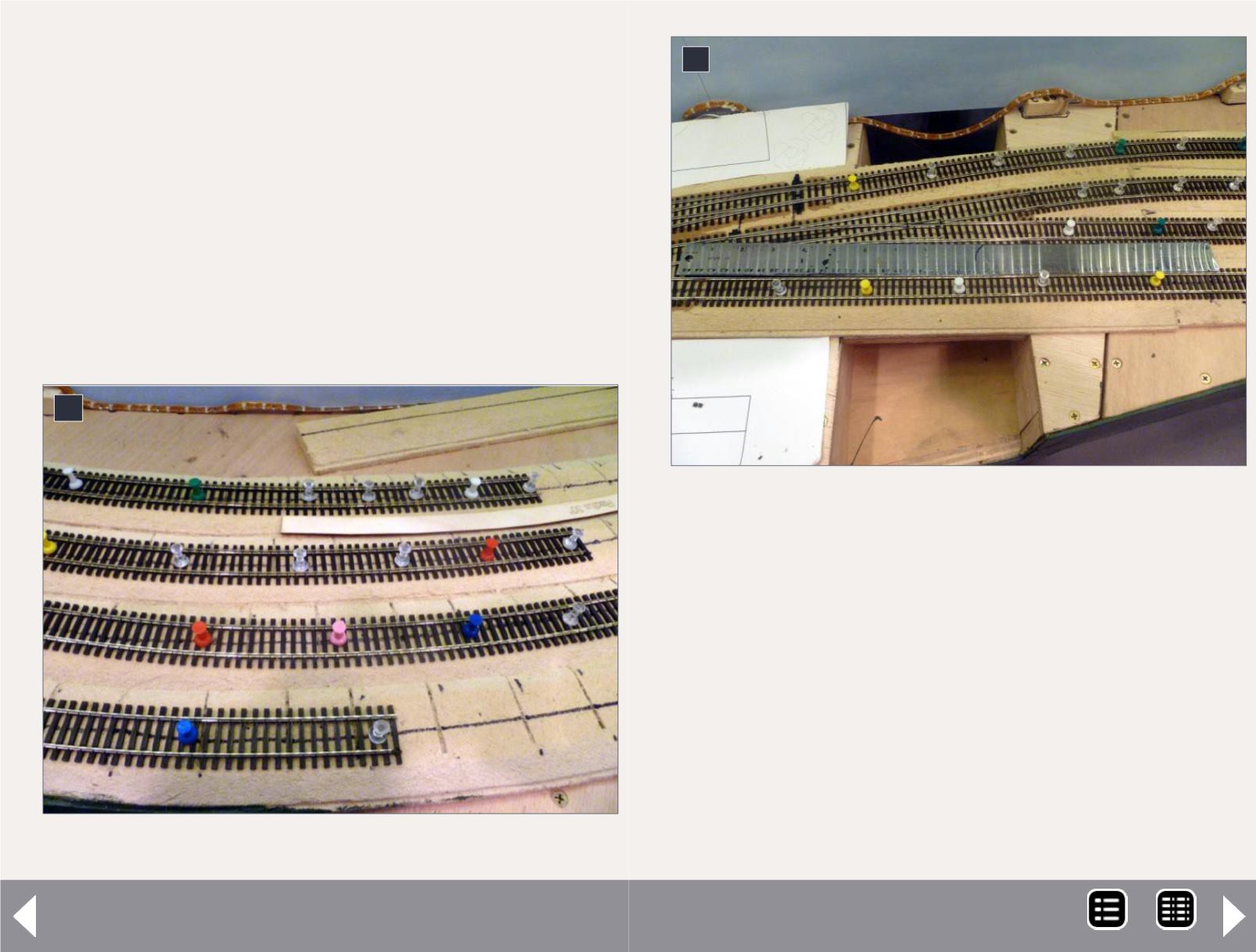

the marked centerline and held it in place with pushpins [1].

1. Track held in position with pushpins.

1

In addition to being faster and less tedious, it is easy to make

lateral adjustments. For straight track, I used a long straight-

edge to align the track. For curves, I used 1/16” wooden tem-

plates cut to match the radii that I was using. This helped

ensure there were no inadvertent kinks, and that the curves

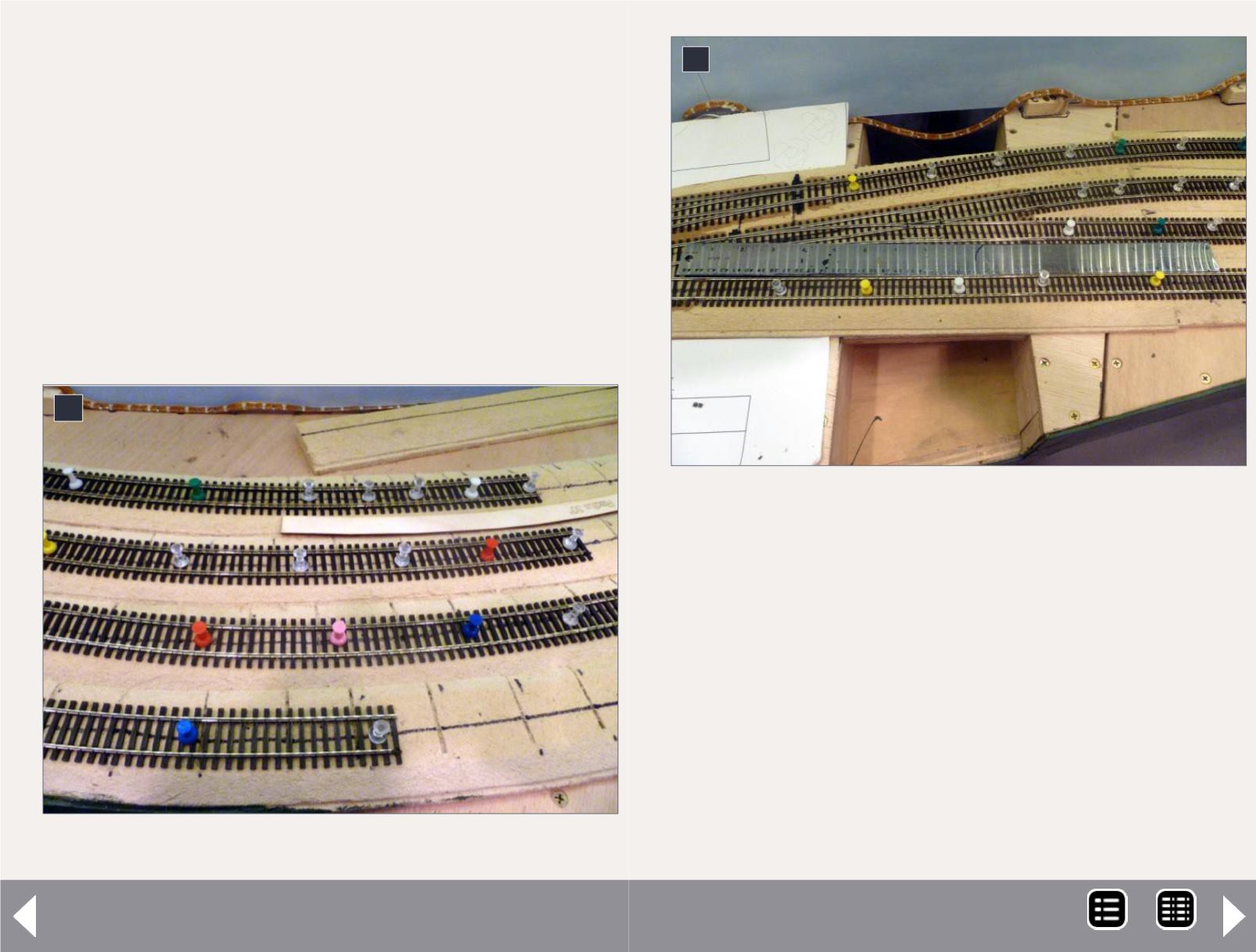

were laid smoothly [2].

Once the track was properly aligned, I needed to fix it in posi-

tion so it could not be easily bumped out of alignment. On a

previous layout, the track was held in place by the ballast and

diluted white glue. As it turns out, this does not adhere very

well to the Delrin ties, and the track can be easily popped

loose, as I discovered on dismantling that layout. So for this

2. A straightedge is used to align straight track.

2

MRH-May 2014