Car roof

This part of the car is very visible on most layouts. A light coat

of dust and dirt will improve realism here if you don’t want to

do heavy weathering. By the way, dust from the layout is not

weathering!!!

Car body sides and ends

Add a light dust on the top and darker grime along the running

boards. Make sure to get the weathering material on the body

under the ladders and grabs to avoid weathering shadows.

Some weathering examples

I am by no means a rolling stock weathering expert. These cars

would no doubt get plenty of “helpful suggestions” if posted on

the weathering forums around the web. I am sharing several of

Batch-building freight cars - 13

them here as average examples of what is possible with some

easy-to-execute, common techniques.

Next month I will walk us through the batch building of four

Proto 2000 stockcars.

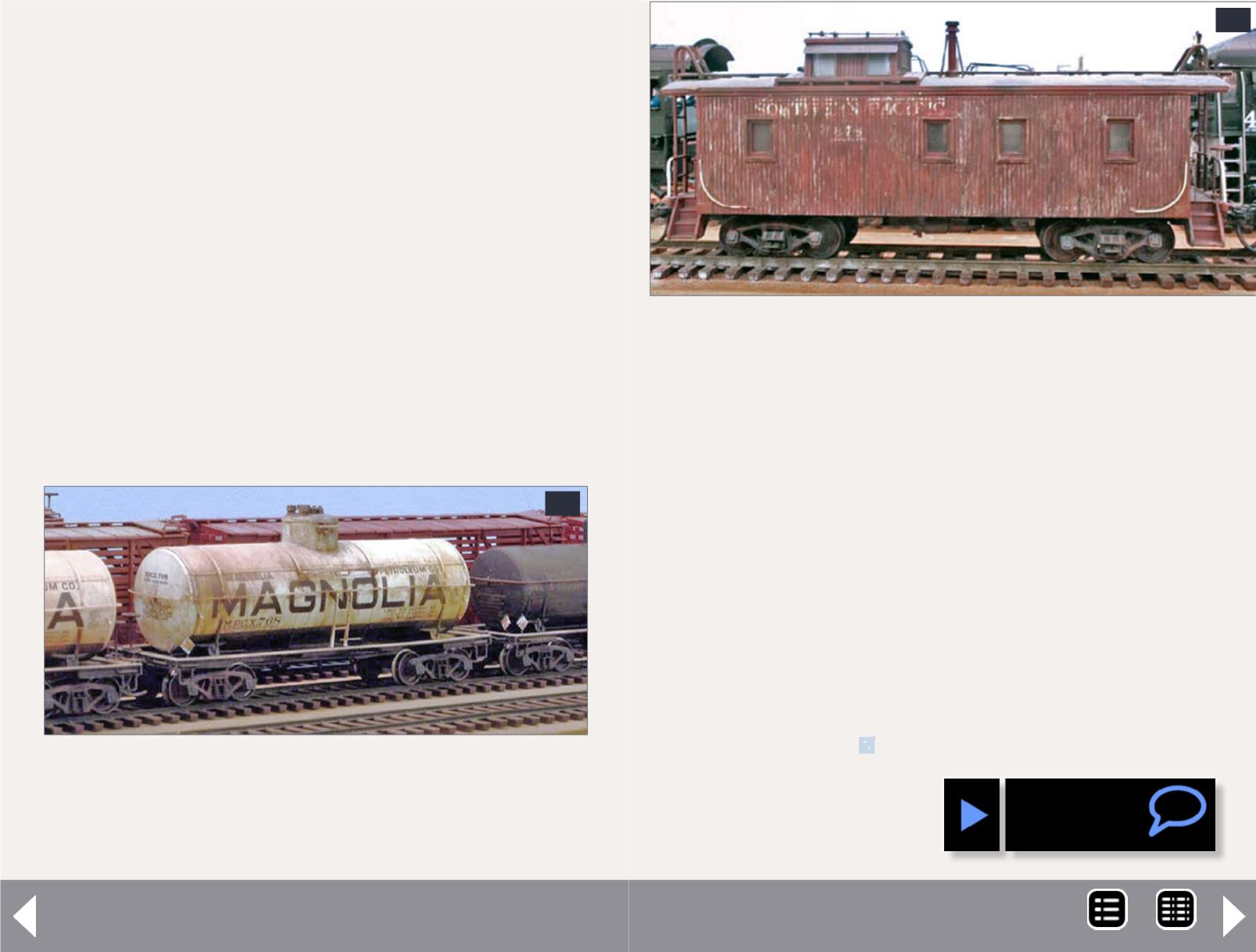

18: This P2K tank was weathered before assembly with

artist oils. Engine black and rust were applied to the

frame and trucks. A final coat of weathering powder

was then applied to the top of the tank after assembly.

21

22

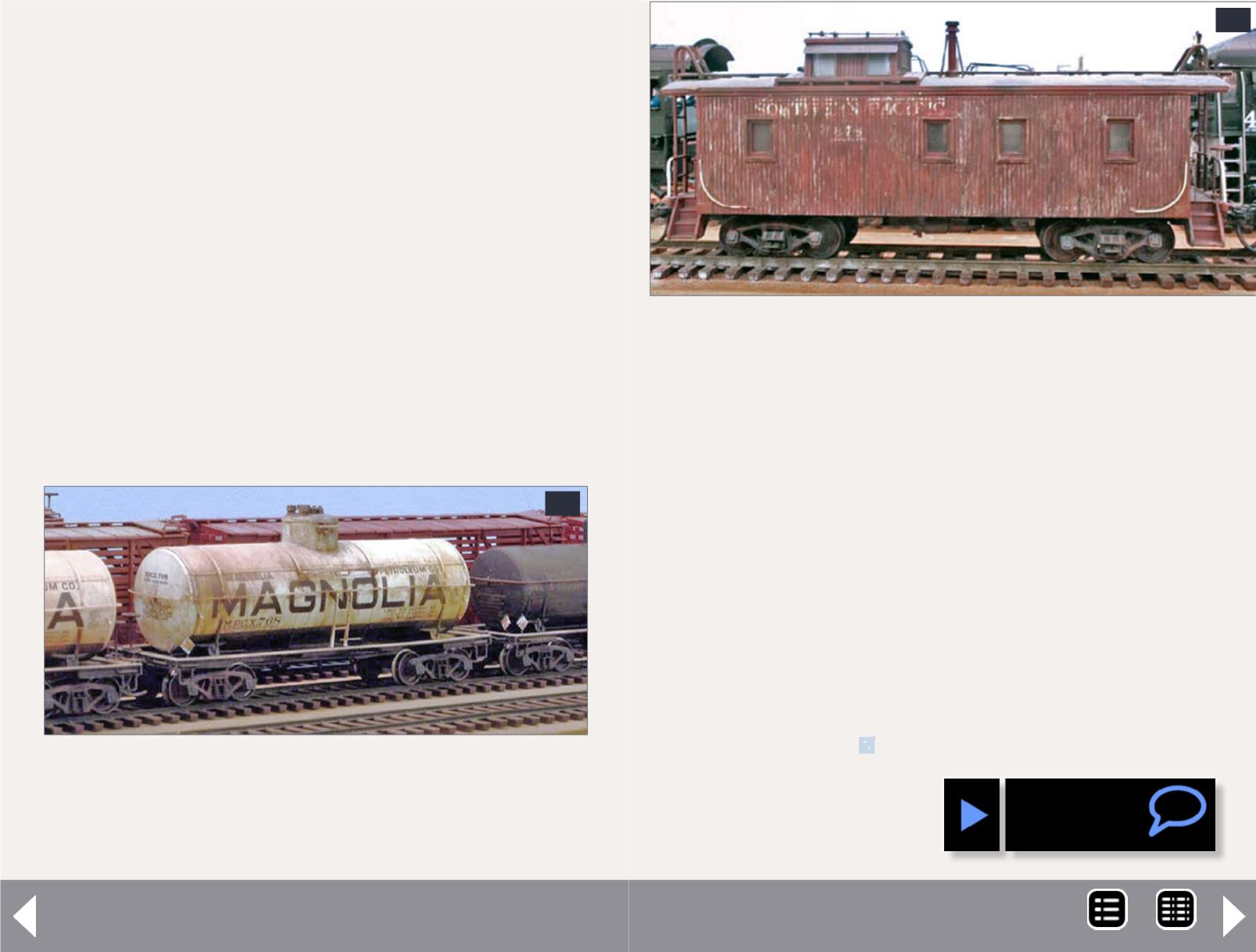

22: Oops! This car has certainly seen better days and

could be taken as a cautionary tale to those who might

tend to get too carried away with weathering. While

“rolling wrecks” were on the rosters of most railroads,

they were often rusting away on sidings, and not in

service. A Walther’s C-30 wood caboose was painted

with gray paint and then had brown applied, and

scratched back to produce the rotting /wood peeling

paint effect. It has been pointed out to me that the

SP would have removed a car in this condition from

service. Oddly, this caboose has been very popular

with crews during operating sessions.

MRH-Mar 2014