Batch-building freight cars - 9

Step four: Cut out and assemble

Next it’s time to start construction. Starting with the first sub-

assembly, locate all the parts needed. Then cut them off of the

sprues and make little piles of each part. In many cases, cutting

off the parts will take more time than gluing the parts together

but don’t rush this step. Total time to cut out parts in our stock

car build was three hours. 38 minutes.

After you have cut out the parts for a particular subassembly,

put the assemblies together one at a time until all of these par-

ticular assemblies are done.

For this stock car batch proj-

ect, I built the underbodies,

and then I applied weather-

ing to the trucks, wheels and

underbodies. Next I built the

car bodies and applied the

roofs. The last step was to

attach the weathered trucks.

Some subassemblies will

benefit from a bit of initial

weathering. For example,

in order to appear realis-

tic, it is necessary to kill the

shine on the wheels, trucks

and underbody. On the

prototype these parts usu-

ally have varying degrees

of grime on them. When

the underbody is done, but

before mounting the trucks,

paint it flat black (or the

body color, if appropriate

to the prototype) and apply some weathering. Do this even if

the parts are already cast in black plastic, I have found that it is

easier to weather tanks on tank cars before applying the rail-

ings and grabirons. Many modelers airbrush and weather car

roofs before assembly as well. The rest of the weathering will

come after the cars are completed.

Step five: Road test:

With construction complete, it is time to perform a road test.

Check the coupler height with a gauge (you do have a gauge,

right?), and adjust if necessary. Make up a string of the new

cars and run them around the layout for a shakedown cruise.

Watch for wobbles, and note if any cars derail (hopefully

none). If the same car derails more than once, pull it off to the

14: This photo of the

workbench shows all the

subassemblies organized

in boxes.

14

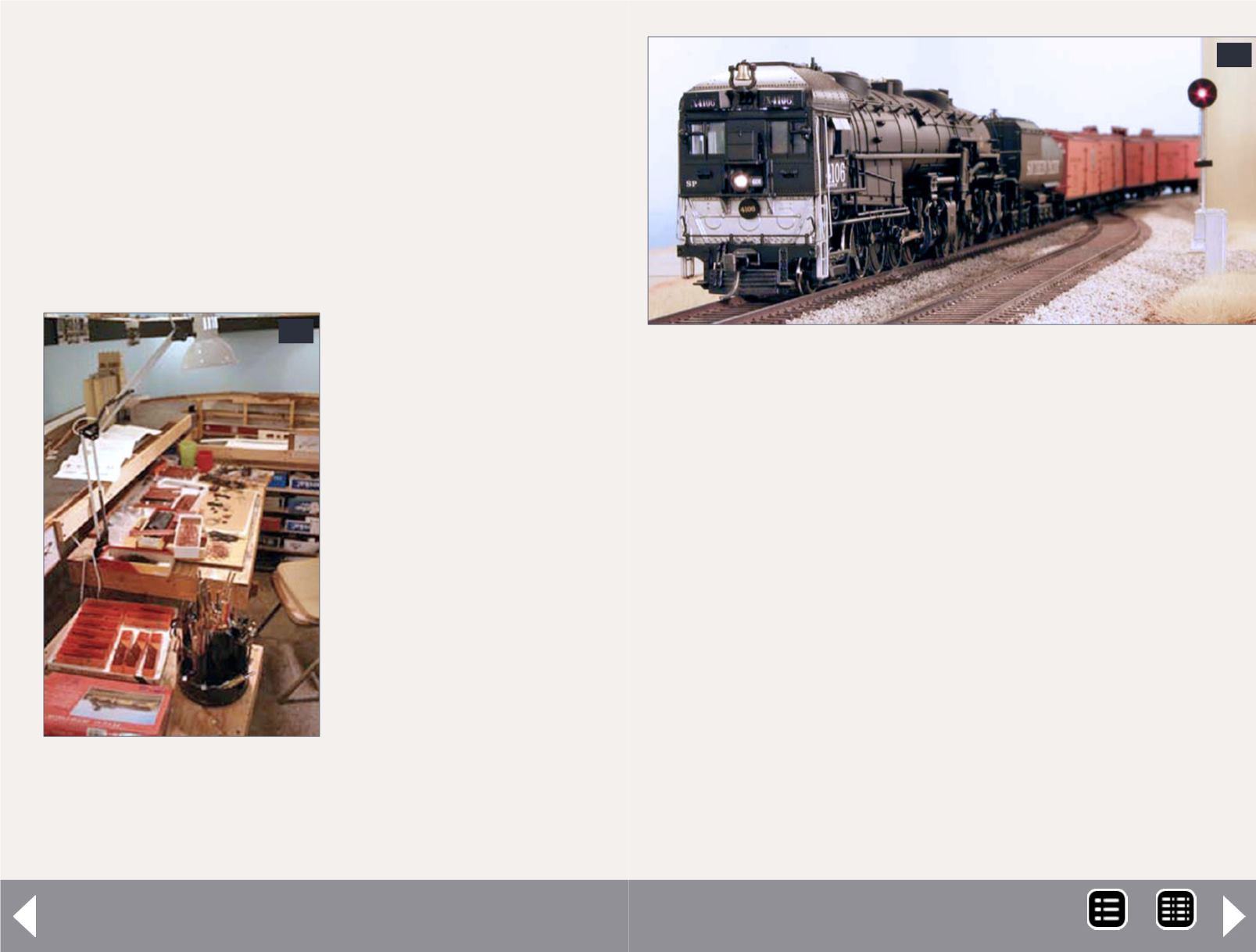

15: A recently assembled string of reefer cars is run

through their paces to determine if adjustments need

to be made. The train usually is run around the layout

a few laps, and then run in reverse to find if any of the

cars need adjustments.

15

MRH-Mar 2014