First Look: Center-beam flatcar - 2

its construction. The center-beam itself is a 0.010” etched brass

piece and appears prototypically slim in profile. It is 8-11/16"

long from the outsides of the bulkheads, and weighs 3.8

ounces, significantly less than the 5 to 5½ oz. recommended by

the NMRA for a car of its length. With very little space to hide

extra weight in its detailed underside, adding weight via a load

would seem to be the most visually acceptable solution.

The car comes with factory-installed Kadee #58 couplers and

the coupler box lids are screwed on, making it relatively simple

for those who prefer a different size or type of coupler to trade

them out. Care should be taken with the fragile coupler cut

levers, which are attached to the lid, air hoses attached to the

side of the coupler box, and the brake rigging in the same area

on the “B” end of the car.

The printing on the model is crisp and clear, down to the tiniest

print in the data panel and the “Thrall Car” logo and, on some

models, the road numbers on the trucks.

History and information on center-beam

flatcars

“Center Beam” is a Thrall Car Co. trademark. The company

built the first of the type in 1969 for bundled lumber traffic on

the Burlington Northern, using a plan developed by Canadian

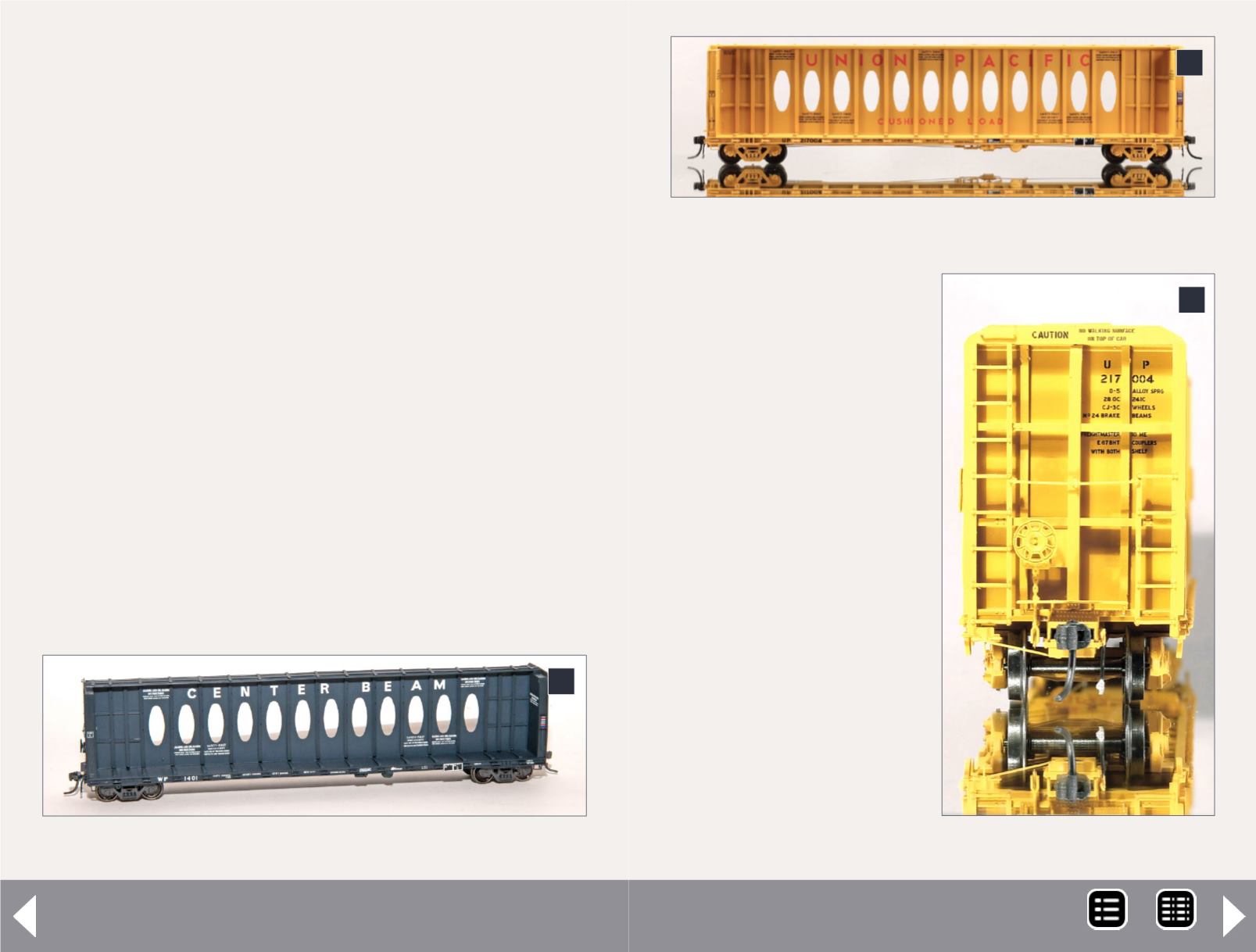

2: WP 1401 (Joe Brugger photo).

2

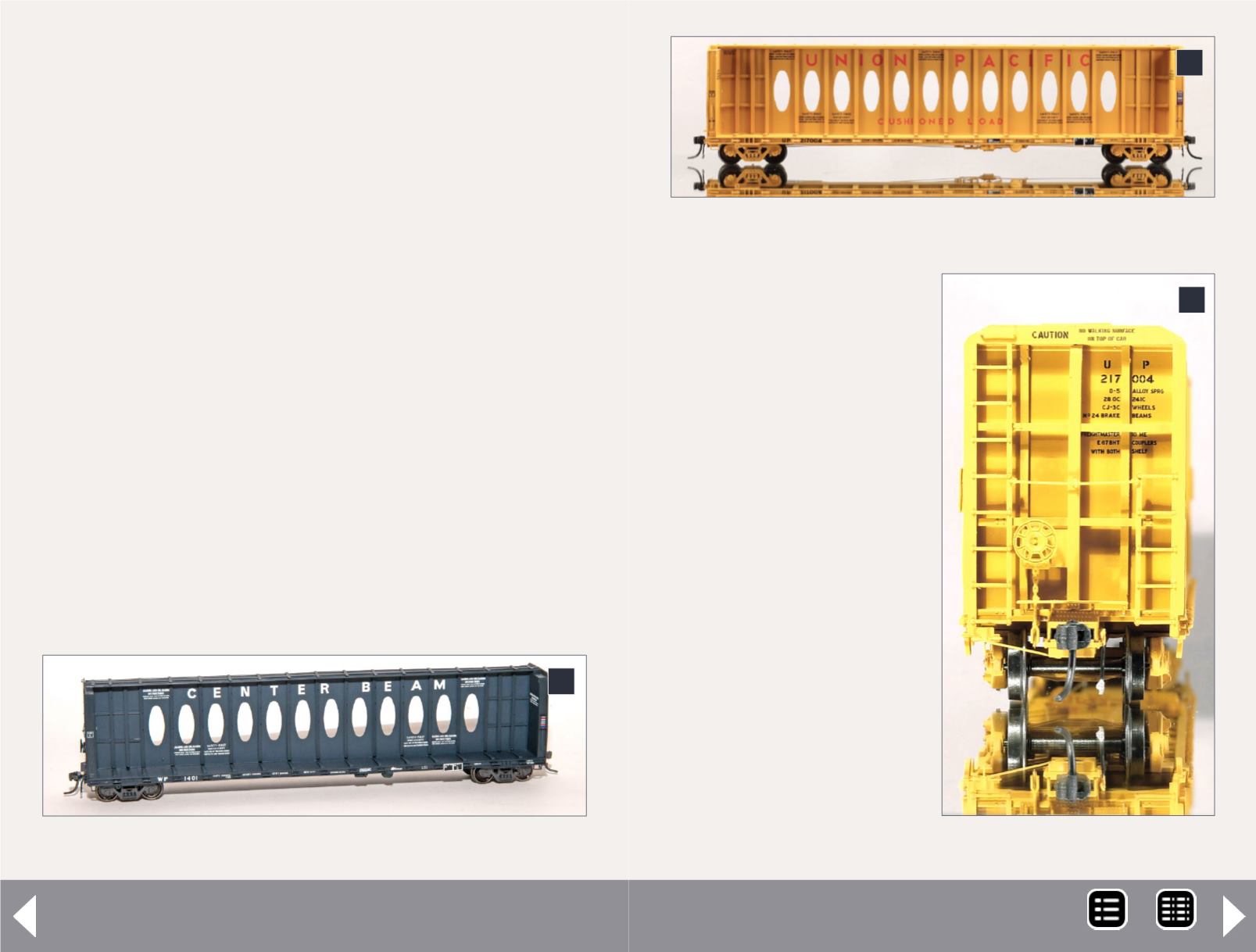

3: UP 217004.

3

4: Closeup of the B end.

4

National. Think of the beam

as a very tall center sill,

improving the ability of a

low-decked flat car to carry

heavy loads. It also ties the

bulkheads, useful on cars

hauling shifty loads like lum-

ber, poles and pipe.

The type has have been

built in several lengths

– 66' between the bulk-

heads for BN, 83-footers

for steel truss traffic on the

Seaboard Coast Line, then

these ExactRail 60' 8” cars in

1977 for Milwaukee, Union

Pacific and Western Pacific.

Later cars were built to 73'

for less-dense kiln-dried

lumber, and Walthers has

offered these. The Front

Range-McKean model car

MRH-Nov 2013