Up the Creek Column - 5

Installing the servos

Installing the servo module – bracket and two servos – is primarily

a matter of getting things well aligned. The first things to position

are the semaphore blades – they should be at the yellow position,

about halfway between the low (green) and high (red) positions.

The next thing to align is the servo bracket. Position it so the two

semaphore control wires drop down between the two servos

and just behind the rear surface of the servo control arms (11).

Connecting the servos and semaphore

I removed the servo control arms from the servos and drilled

them with a #77 bit (.018") which was a couple thousandths

larger than the semaphore control wires. The control wires will

pass through these holes and slop needs to be minimized.

10

10: I mounted the sema-

phore by holding it in

place and tracing its out-

line with a sharp pen-

cil. With the semaphore

removed again I drilled

tiny pilot holes for Micro

Engineering small spikes.

I reinstalled the sema-

phore, double checked

its alignment and added

six spikes spaced around

its base. These appear to

hold it very securely.

The photo shows the

spikes before they were

driven home.

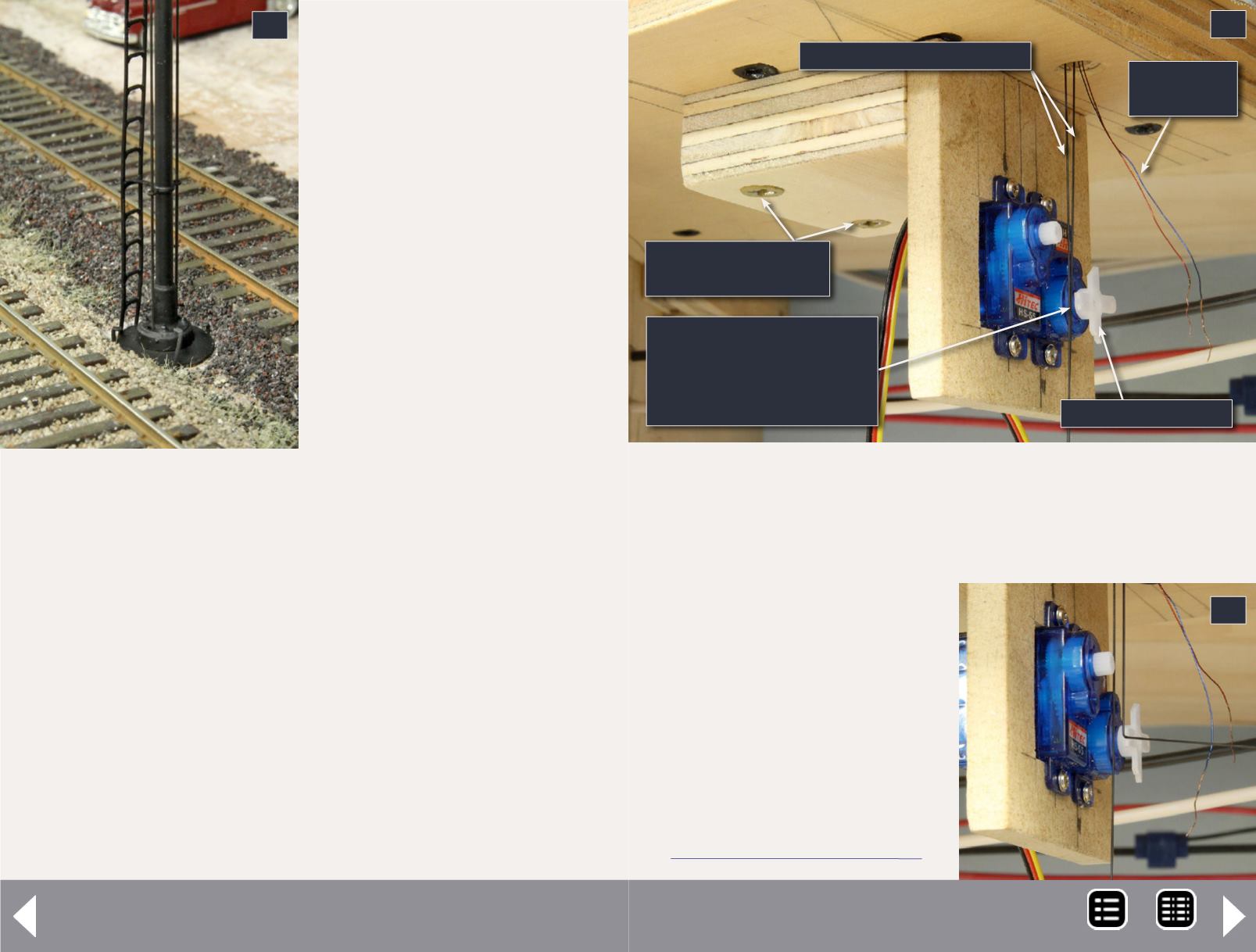

11: The servo module, aligned below the train order

semaphore and screwed in place.

12: A semaphore control wire bent to pass through a

servo control arm hole.

11

Servo module is located

such that the control

wires pass closely behind

the control arms.

Screws secure the

module to roadbed

LED power

leads

Semaphore control wires

Servo control arm

I fit the newly drilled servo

control arms back on the

servos and put a 90

o

bend in

the semaphore control wires

where they will pass through

the control arms (12).

The final step is threading

the semaphore control wires

through the servo control

12

MRH-Oct 2013