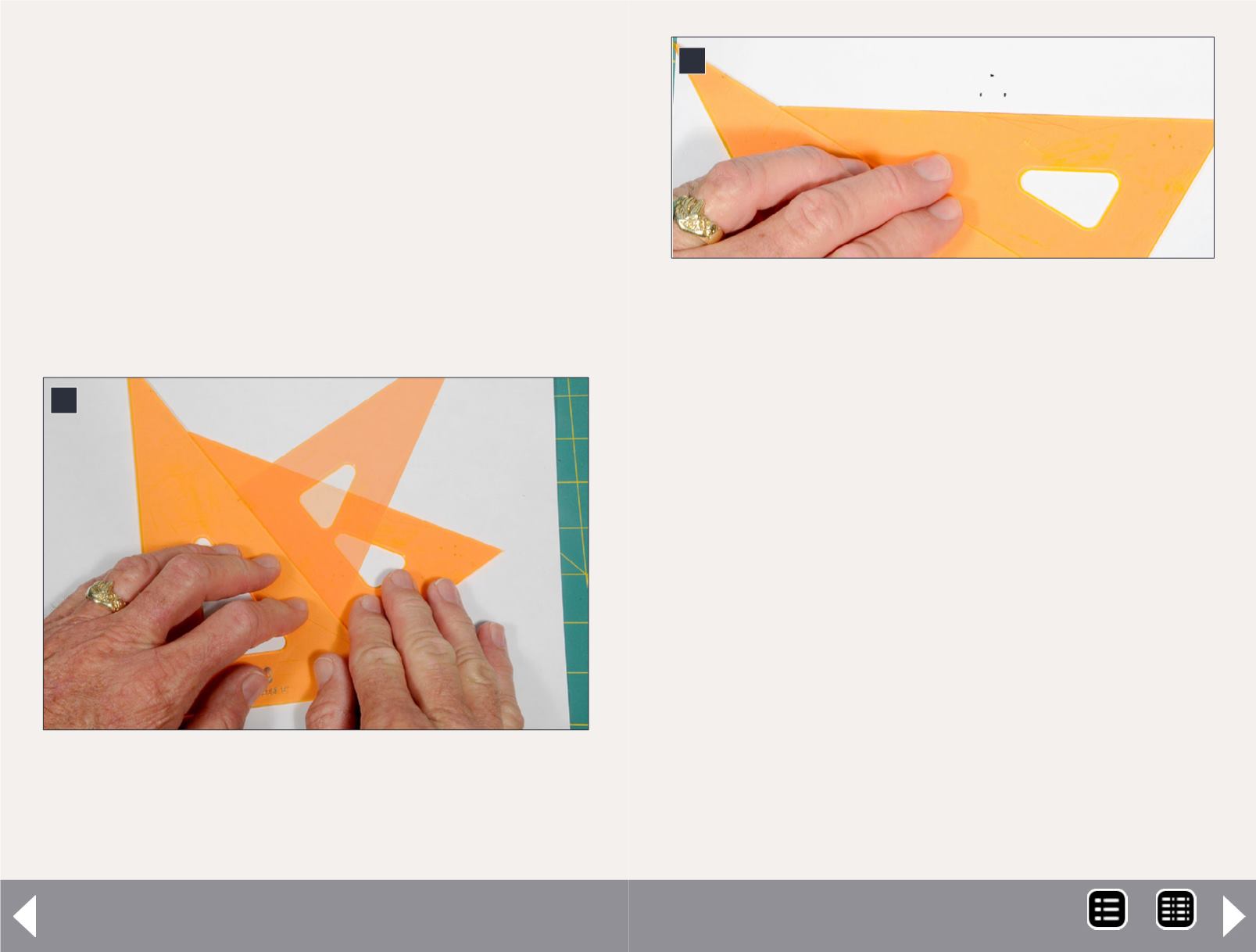

8: By turning the “sliding” triangle 90°, as shown by the “ghost

image”, you can easily draw or cut something at a 90° angle to

the base line. The 90° angle is formed in the space between the

two triangles directly above the middle finger of my right hand.

8

Here is another trick using the same technique. If you need

to cut a number of strips of masking tape into narrow strips

to mask truck wheel treads, cut a piece of masking tape a

few inches long and stick it to a piece of plate glass or other

smooth surface which won’t ruin the adhesive. Set up your pair

of triangles and then simply cut one strip after another, mov-

ing the sliding triangle along the fixed triangle to create parallel

cuts and thus parallel strips of masking tape.

Making two lines perpendicular to each other is also easy with

a pair of triangles. One method is to align one triangle with the

base line and then simply place the second triangle in a right-

angle position to it. However, I always use a variation of the

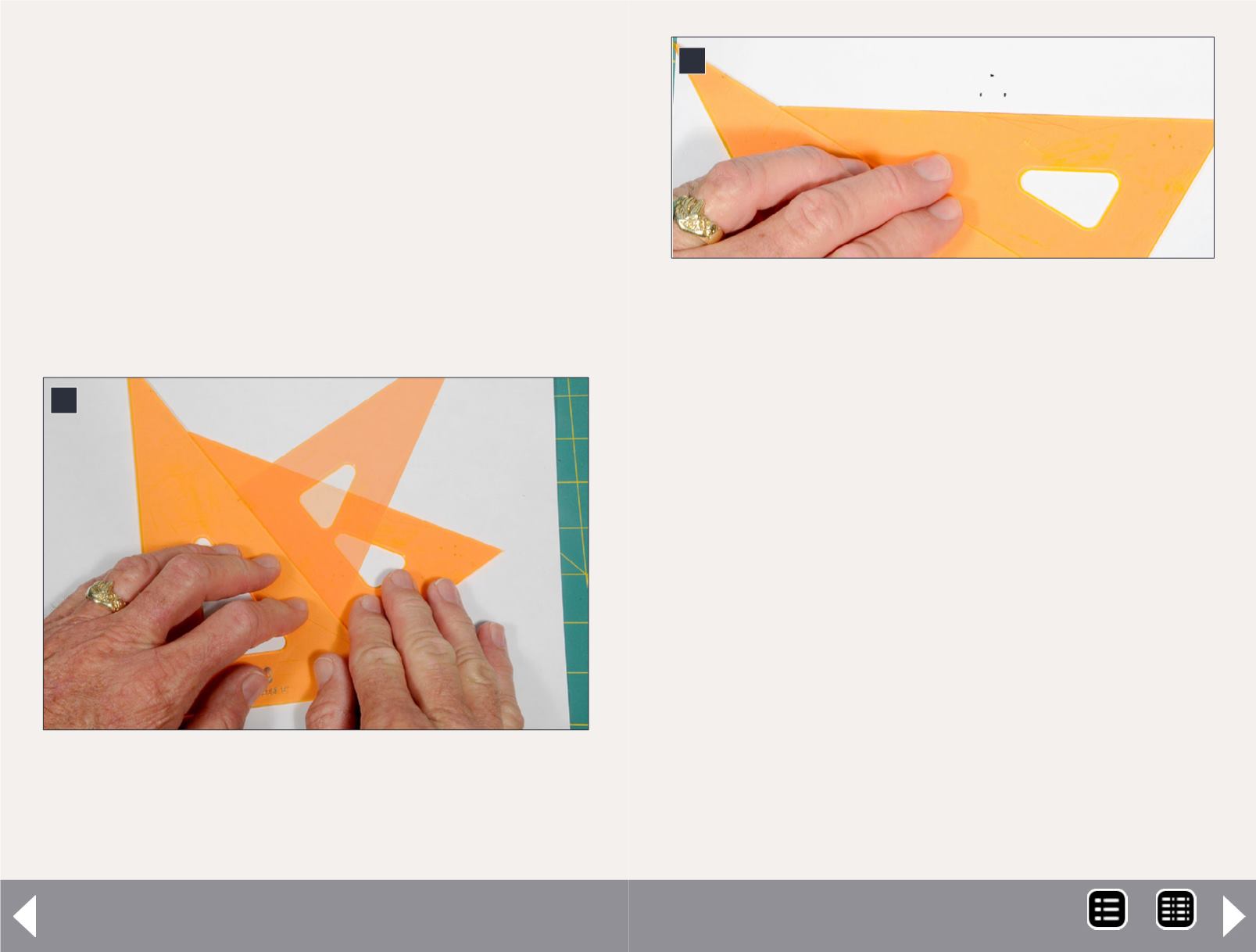

9: These four photos show how you can easily make a template

for cutting a sheet of clear styrene to make window glass for a

window casting. There are pencil marks on the paper for the hor-

izontal and vertical extents of the window opening. In this view,

the sliding triangle is aligned with the bottom pencil mark.

9

“parallel line” technique discussed above. As shown in Photo 8,

hold the pair of triangles together and align the sliding triangle

to the base line. Then, while holding the fixed triangle, turn the

sliding triangle 90

o

degrees as shown and you have a 90

o

angle.

Here is a practical application using two triangles shown in

Photo 8. Let’s assume that you want to cut some clear styrene

to fit inside a cast styrene window. You can easily make a win-

dow tracing template to make this task very easy.

Start by measuring the width and height of the opening in the

window casting and transfer those measurements to a piece

of paper with pencil marks. Envision the window casting on

the paper and make the marks roughly in the middle of the

two sides and middle of the top and bottom. The marks on the

“sides” should be equal to the width of the “glass” for the win-

dow opening, while the top and bottom marks should be equal

to the height of the glass.

The tool shed - 5

MRH-Aug 2013