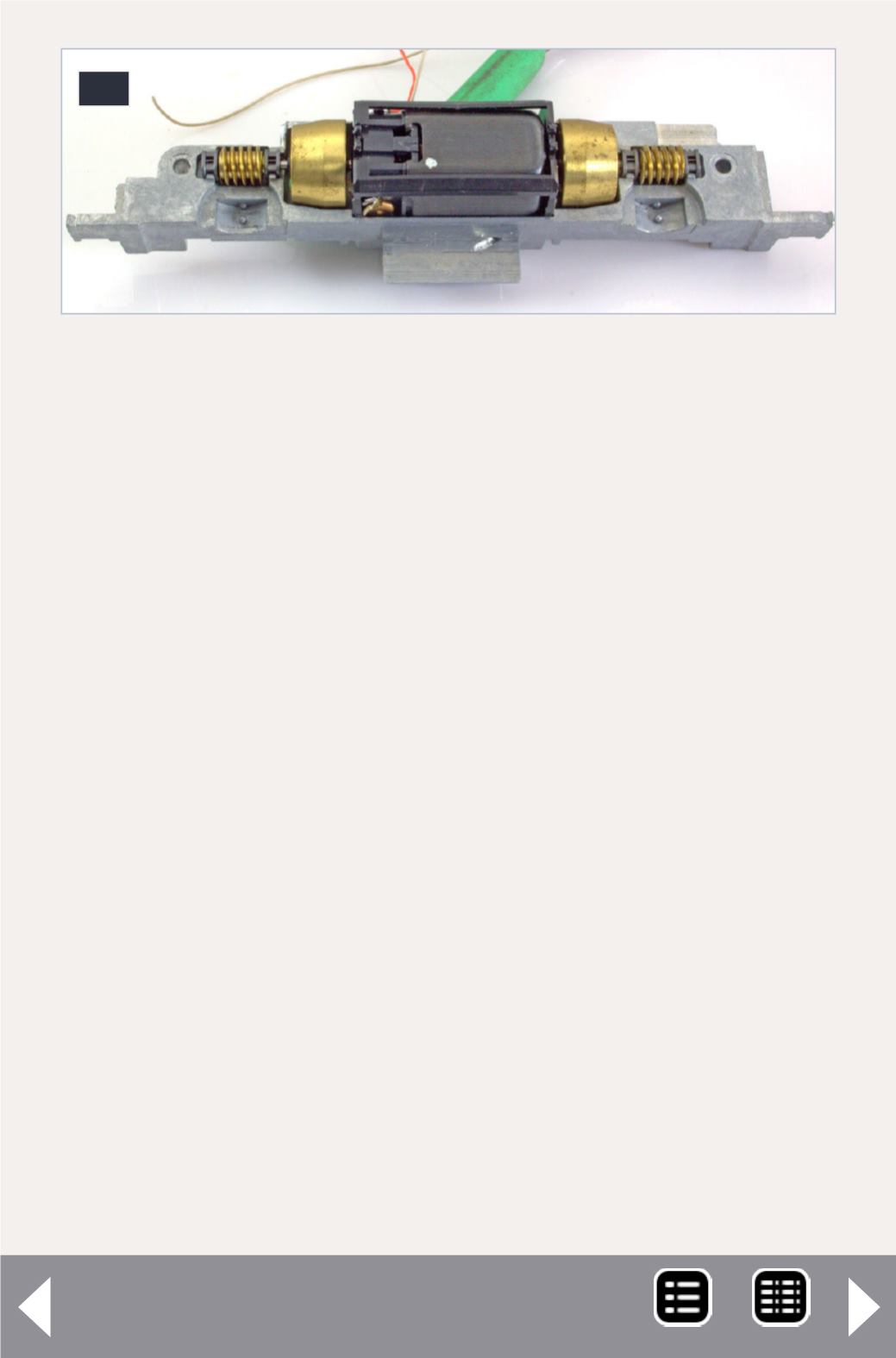

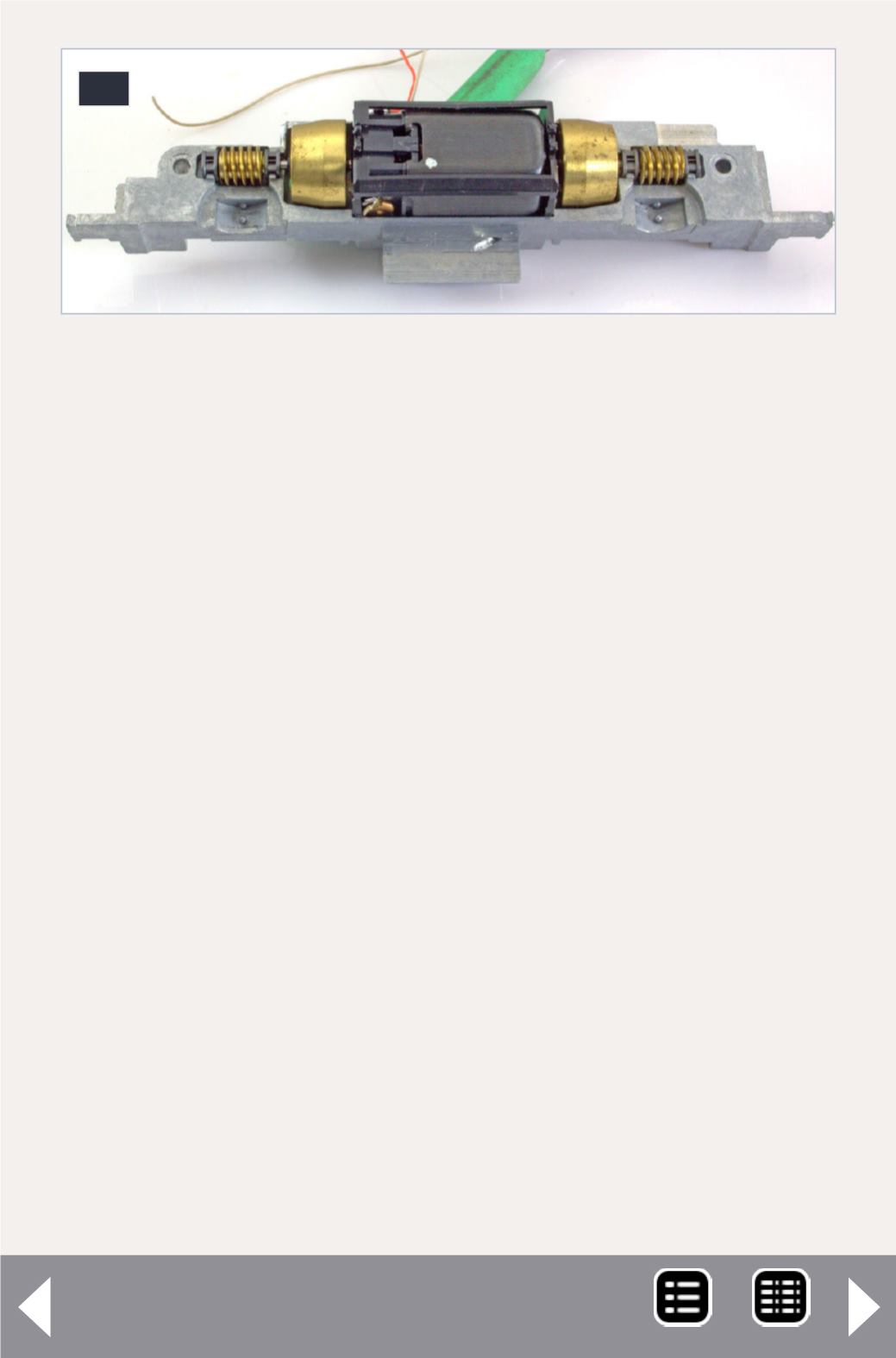

the worm gears, the adapter sleeves and the motor into the

left frame half, as shown in figure 19.

6.4 Position motor wires

The motor wires need to be routed out the top of the frame

in such a way that they won’t be cut by the frame. The wires

need to be positioned so that they won’t contact either frame

half. See figures 15, 19 and 20. If you have any questions, use a

piece of Kapton tape to prevent a short. The motor in figure 19

didn’t have any clearance issues. The one in 20 might, so I used

Kapton tape, just to be sure. After the photo (20) was taken,

the motor mounting clip was rotated around the motor shafts

until it was in the position shown in figure 19.

6.5 Assemble frame halves and trucks

The next step is to put the cleaned trucks into the left frame

half and put a drop of 10- weight Nano-Oil where the truck

slides on the frame.

6.6 Lightly tighten screws

Once you have the parts positioned as shown in figure 21,

slide the other frame half over the drive train and tighten the

19

19: Drive train reassembly ready for trucks and

insulators.

DCC Impulses column - 12

MRH-Jan 2013