potentially troublesome contact locations: the sliding contact

between the trucks and the copper strips and the non-sliding

contact between the copper strips and the frame halves. This

should improve your operational reliability.

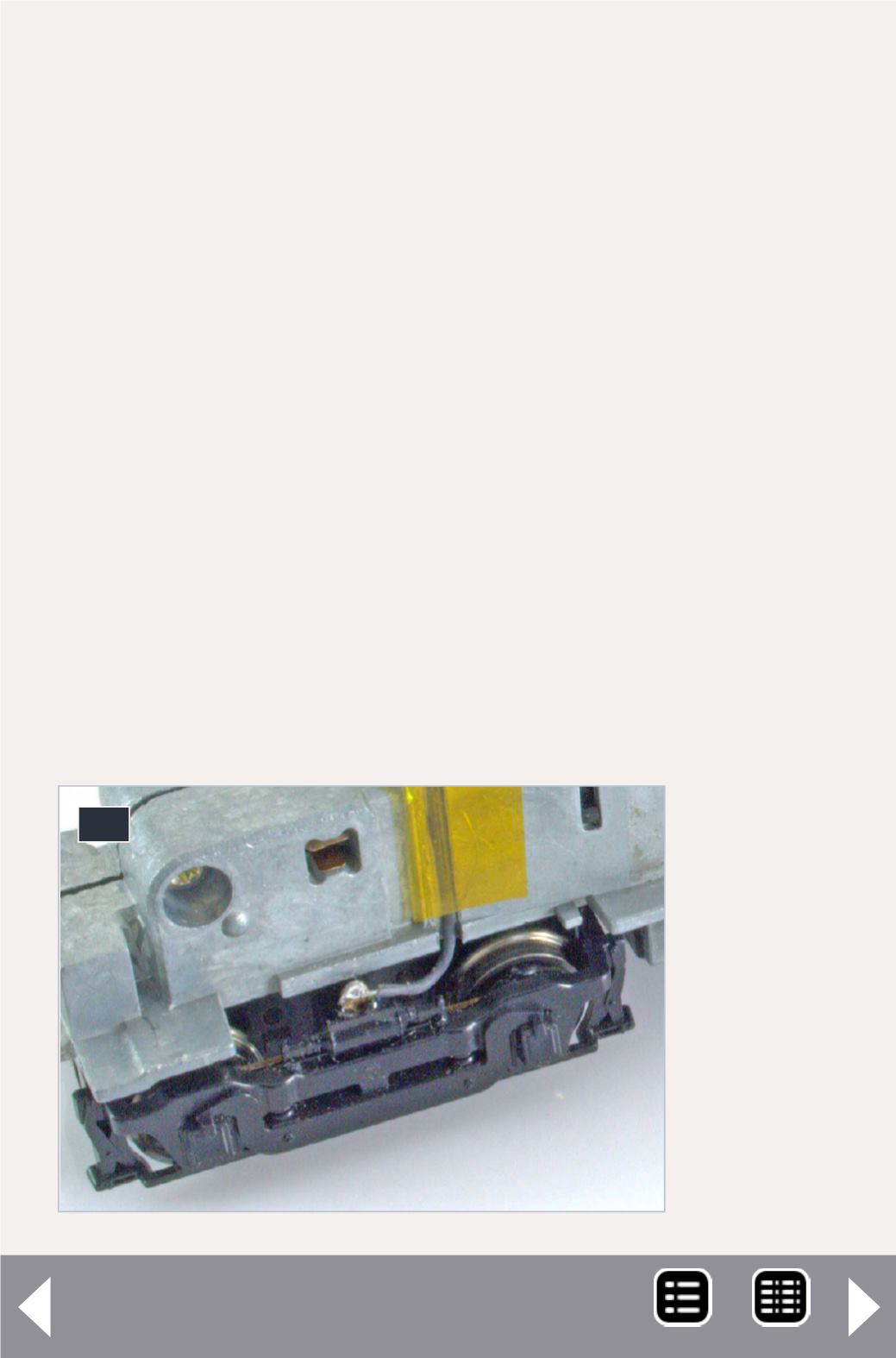

9.1 Solder wires to trucks

Use a motor tool and a brass brush to clean off the contact point

at the top of the truck. Quickly tin the point. Strip and tin some

Wire-2951 and quickly solder it to the tinned contact point. You

need to be quick with your soldering so as to not melt the plas-

tic details on the truck side frame. Cut the wire about 2 inches

above the frame. This is a bit long, but I don’t want to be short

and need to redo the solder joint on the trucks (24).

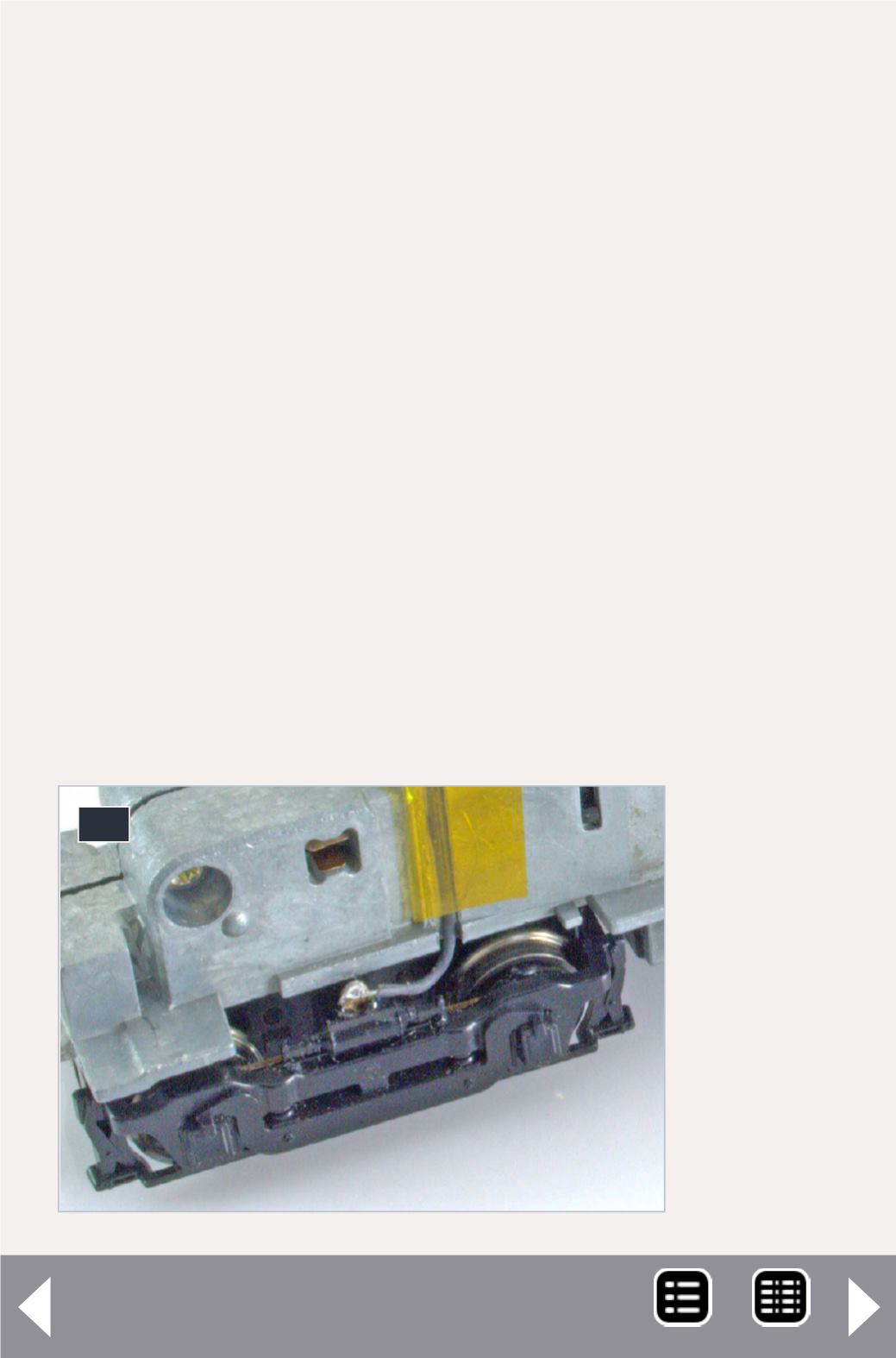

9.2 Secure truck wires to frame with

3/8” Kapton tape

Once you have all four truck pickups wired, apply 3/8-inch

Kapton tape to hold the wires in their channels. When you are

done with this step, your loco should look like figure 25.

24

24: Close

in photo

of the

wired

truck after

step 9.2

is done.