running (that is, switching) it has. Compute the max-to-main value

as:

max nbr of cars / mainline track cars

to get a percentage, with

the results meaning:

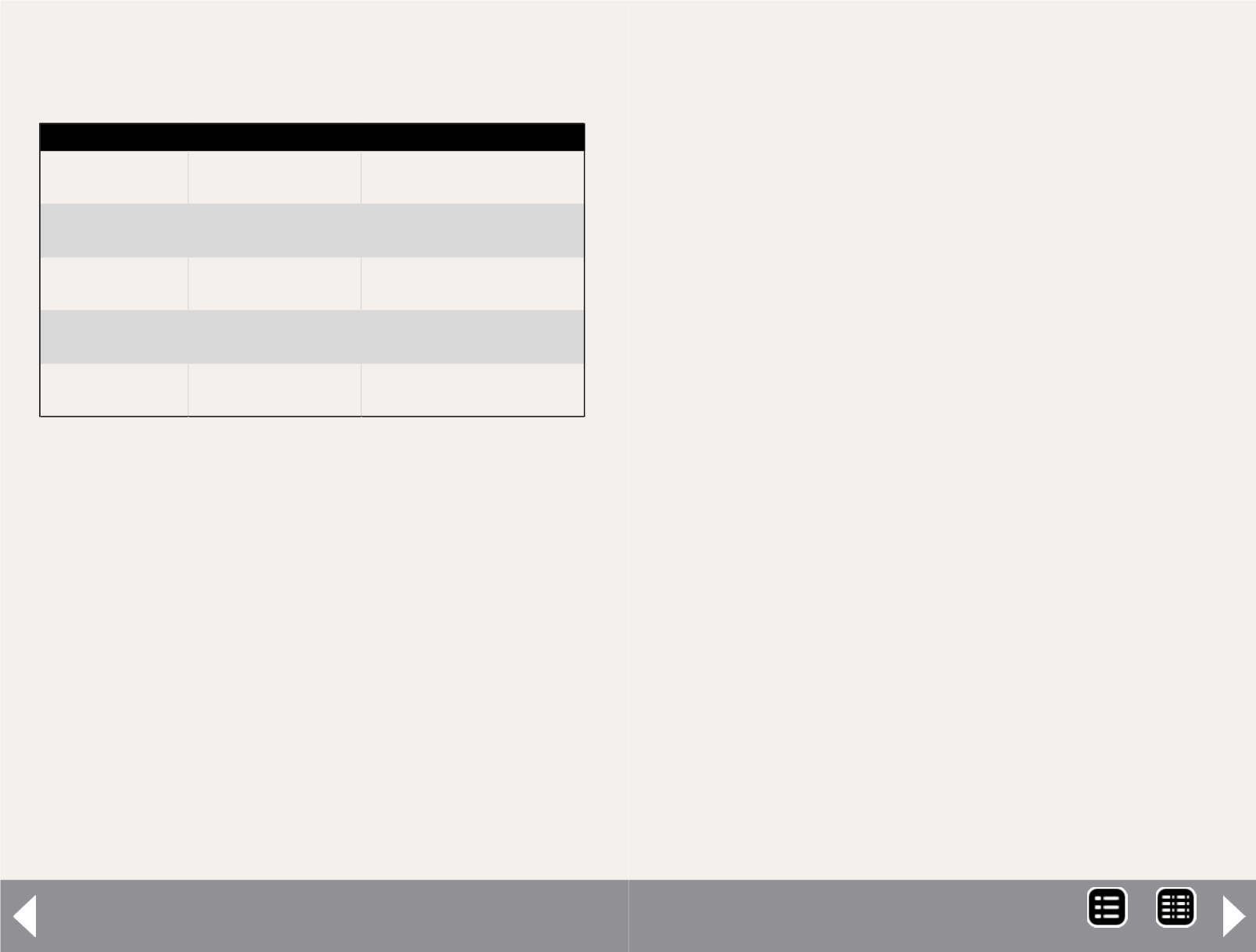

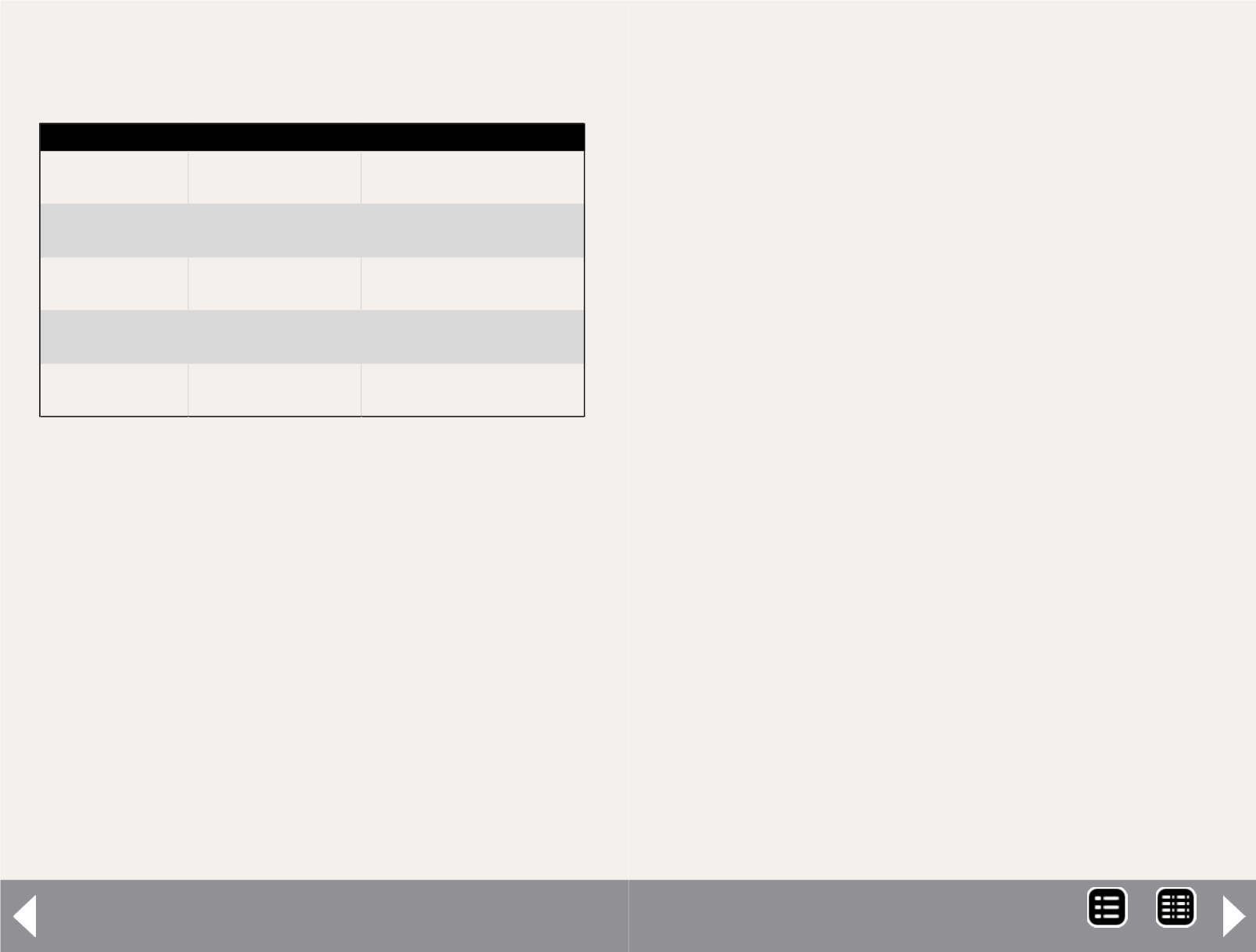

Percentage

Summary

Comments

Under 50% Mainline focus Focus is mainline running;

little switching

50 - 80% Mainline emphasis High amount of mainline

running vs. switching

81 - 120%

Balanced

Mainline running and

switching balanced

121 - 150% Switching emphasis High amount of switching

vs. mainline running

Over 150% Switching focus Focus is switching; little if

any mainline running

NUMBER OF CARS MOVED:

The number of cars moved in a typi-

cal operating cycle can be computed as: 4

0% of (staging x 2 +

passing + connecting)

. To increase the number of cars moved,

we need to increase some combination of staging, passing, or

connecting trackage.

Notice staging is particularly effective in increasing the number of

cars moved, since for every train that leaves staging, another can

move in to replace it, meaning twice the cars can be moved (if they

are available elsewhere on the layout). In effect, staging acts as

both connecting track and passing track – thus serving double duty.

Another thing we can do to increase cars moved is stop using some

track for storage, and designate it instead to be either staging, pass-

ing (if trains can legitimately “pass” on this trackage), or leaving it

undesignated and always free of stored cars, so by default it be-

comes connecting track.

Layout design assessment - 8

TRAINS:

We can divide the number of cars moved by our average

train length to arrive at the average number of trains we can expect

in a typical operating cycle.

Average train length is the smaller of

average passing train length or average staging train length

.

One operating cycle is defined as running the layout in a realistic

manner until the trains you run begin to repeat. Ordinarily this will

be one “24 hour” day according to the modeled train schedule. De-

pending on our fast clock ratio, the experience of our crew, the reli-

ability of our equipment, the length of a typical run, and the level

of detail to which we simulate prototype operating practices, the

actual time it takes to complete one cycle could vary from one hour

to dozens of hours. Three to four hours is probably a good typical

cycle, however.

DISPATCHING THRESHOLD:

Compute as:

(3 x shortest passing sid-

ing + 2 x average passing siding + longest passing siding) / 6

. Two

opposing trains of this size or larger will tend to create a dispatch-

ing bottleneck because they cannot easily pass each other except

at select sidings. If you want to ease the dispatcher’s workload,

keep the typical train length at or under this size.

If you want the dispatcher to more easily manage longer trains,

then lengthen your passing sidings. The best way to increase this

threshold is to lengthen your shortest passing sidings first. Of

course, you need to keep the length of your staging tracks in sync

with passing siding lengths as explained above under the train

length stats.

Another less obvious tactic to improve this stat (if your passing

sidings are smaller than your staging tracks) is to declare very

short passing sidings to be switching runaround tracks only

(and thus connecting track instead of passing track), thereby

removing them from routine consideration as locations where

MRH-Oct 2014