Lite and Narrow Column - 3

I added pre-painted Northeastern corrugated metal roofing,

which is embossed paper, to the walls, overlapping the sides

and bottom of the section to seal the building.

The advantages of using the paper panels are, there isn’t any

shiny metal showing, and it is easy to weather. This is just one

way to construct the metal-sheathed part of the tipple.

In his article, Ron Pearson drew the external walls of the tipple

on .060” styrene. He scribed the styrene and snapped it apart,

giving him straight edges.

3

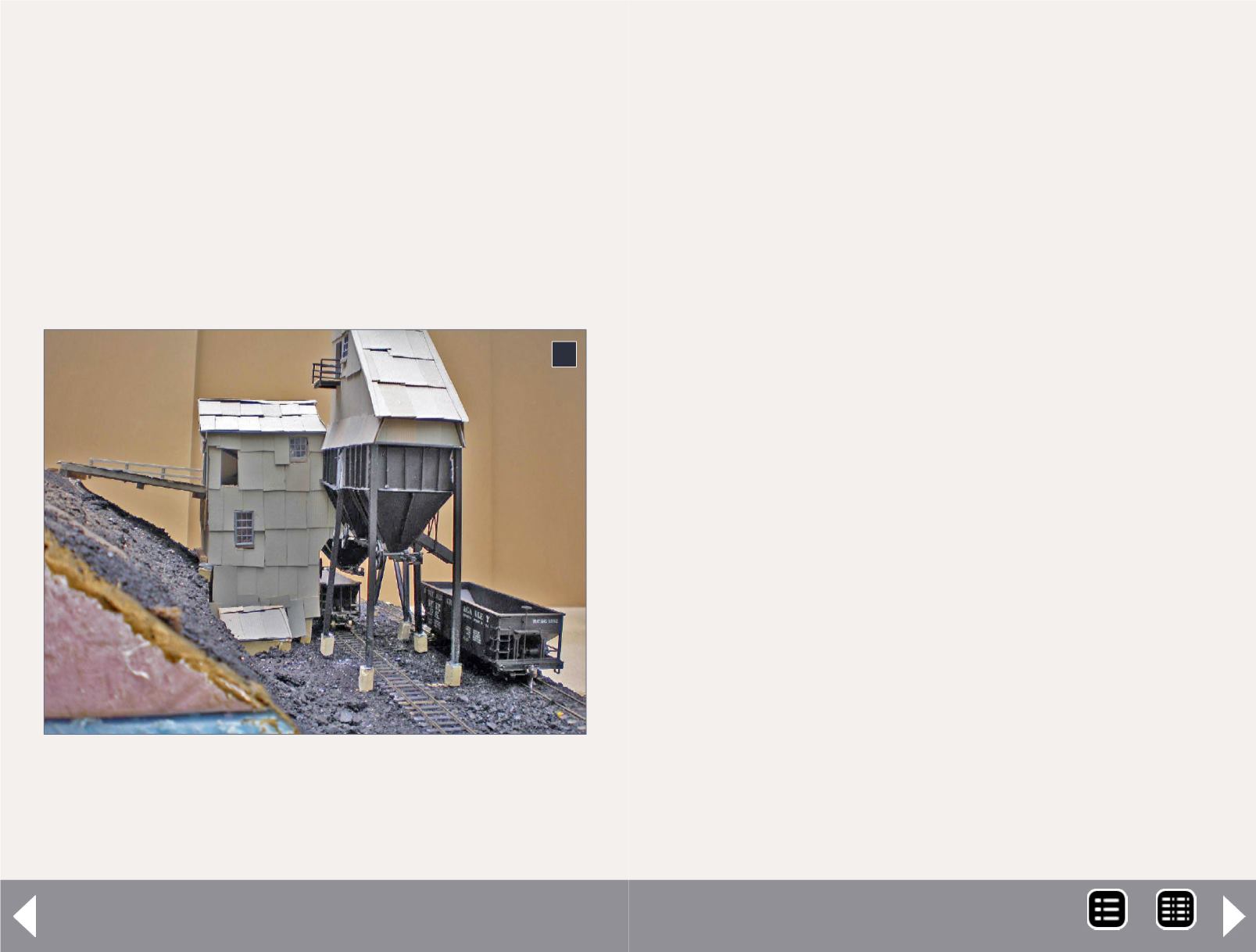

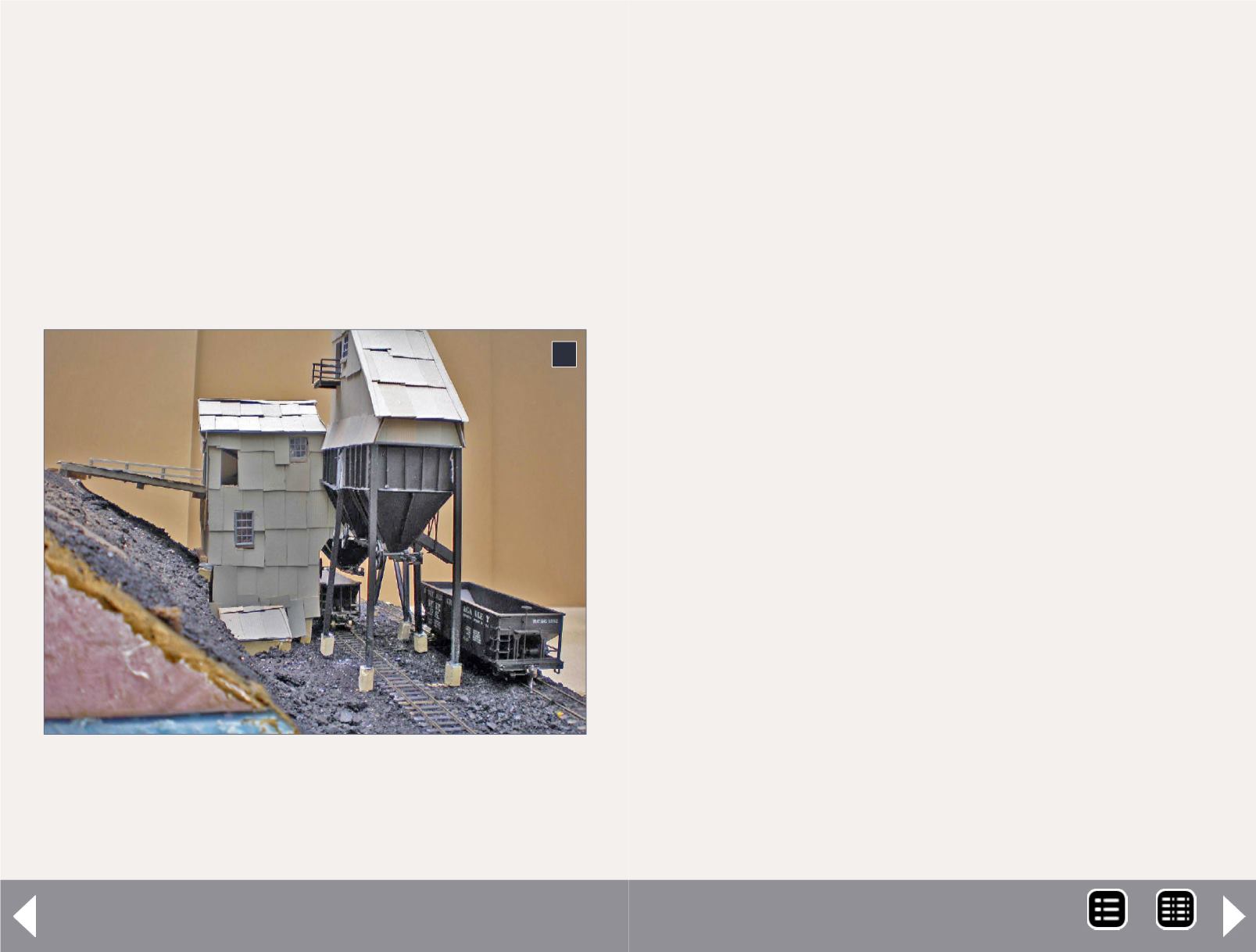

3. East side of the tipple showing the covered pit that

was mistaken for another shaft. The steps have yet

to be installed as well as the waste chute from the

shaker house.

Ron marked the locations for the windows and doors and cut

them out. He then glued Evergreen 9” H-beams in the corners.

Over the styrene sheets, he applied Campbell’s corrugated

metal cut to 4’ wide sheets.

The Northeastern and Wild West Models corrugated paper

could be used with this type of construction as well, but these

products weren’t available at the time Ron built his models.

Those of you in larger scales may substitute either foam-

core board or thicker styrene for stronger walls. Also, the

Northeastern corrugated paper is available in O scale.

Alternative methods

Another method for making the walls is a combination of

open frame and solid styrene. For the areas where the steel

work is visible, such as through the large opening at the rear

of the tipple, using the open steel work so that the bracing

can be seen, as in the prototype photos, and solid styrene

walls when it can’t.

However, using this method requires the corrugated metal

or paper to be finished on both sides in the visible areas, as

with the open frame type of construction. No matter which

method you use, do not enclose the building over the tracks

until the loading bin has been installed. This will make for

much easier installation.

Once the framework was complete, I installed the dumping

floor of the tipple. To better support the floor, I added additional

H-beams. The floor was installed using individual 2” x 12” scale

lumber and was stained with Builders in Scale Silverwood.

The mine rails come from the mine to the tipple across the

ramp. To locate the mine rails, find the center of the structure

MRH-Aug 2014