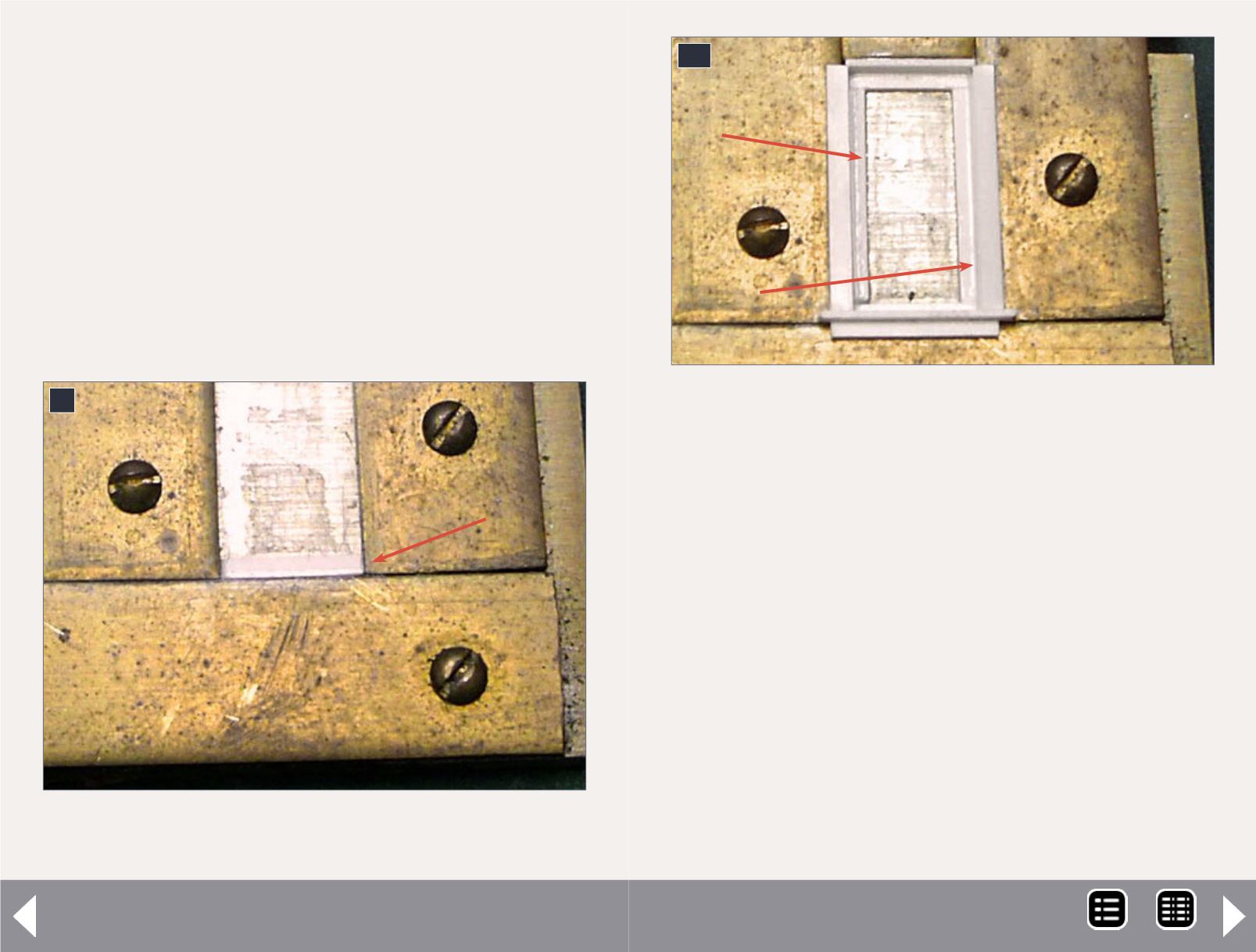

9. Begin by placing 2” x 6” pieces in the jig. The arrow

is pointing at the header.

9

bottom of the window opening in the jig, as shown above.

Notice that when you place the pieces in the jig vertically,

they come up even with the surface of the brass strip; this is

why I specified that you use only 0.064”-thick brass strips in

the jigs. When using the Chopper, place the pencil mark on

your piece of styrene over the slot in the tool steel, and cut

the piece to length.

Now open a package of Evergreen #8204 2” x 4” scale lumber,

and cut two pieces the same length as the 6x6s. Place them

on-edge on top of the 2x6 and glue them to the 2x6, using MEK

and a paint brush.

Windows and doors - 6

3

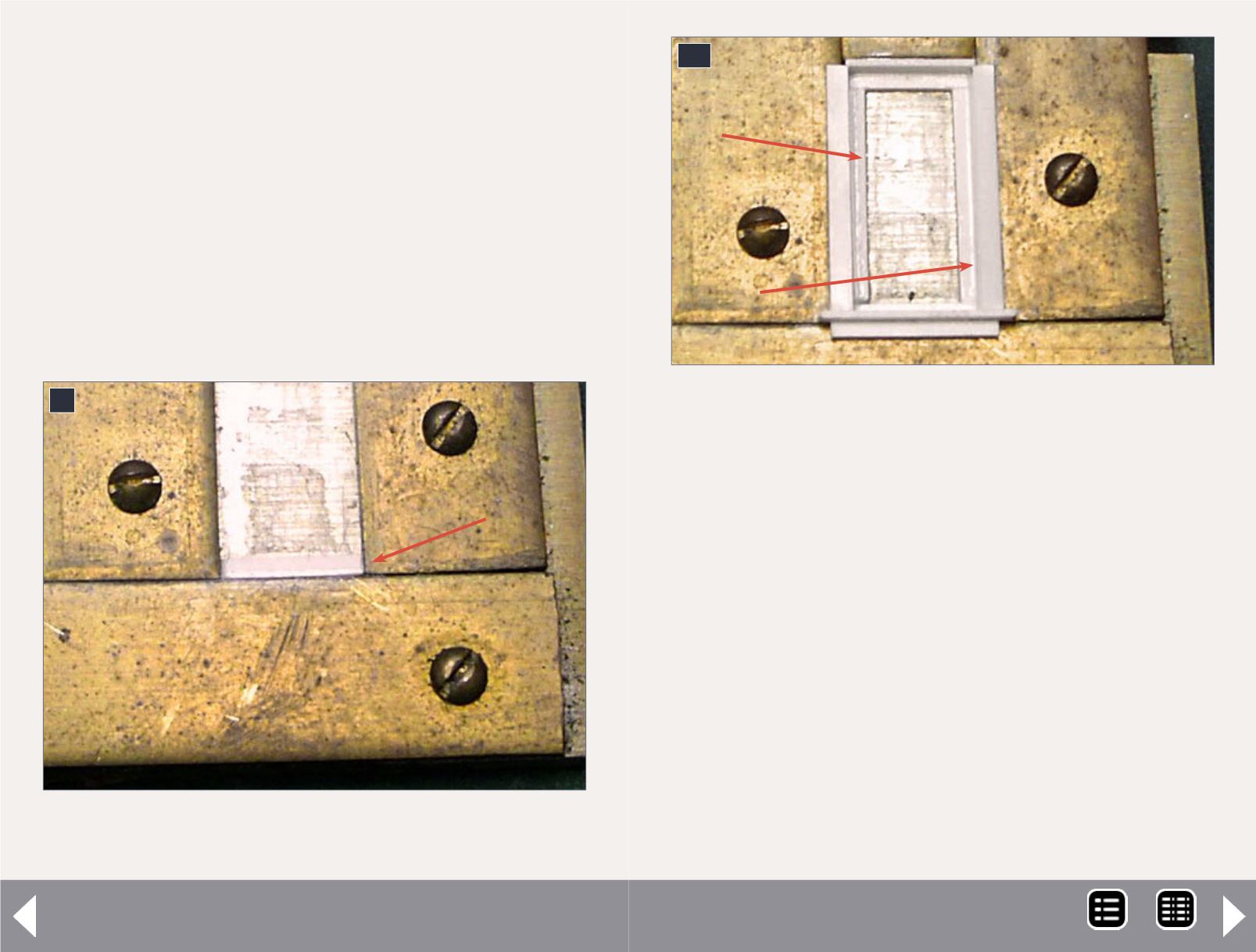

10. Here the window frame is almost complete, just

needing the header. The side rails of the window are

also in place. The arrows are point to the sides of the

window.

10

I keep Tenax-7R, MEK, and styrene putty in clean, old Floquil

paint bottles in holes bored into a block of aluminum on my

workbench. I also store two paintbrushes in the block. To make

this styrene putty, fill a paint bottle halfway up with MEK. Next

add scraps of styrene to the bottle. The MEK will turn this sty-

rene into styrene putty, which you can use to patch or fill any

defects in your styrene structures. The beauty of this method

is that styrene binds perfectly to styrene and does not shrink,

allowing you to file or shape the patch, and then paint it.

In [8] you can see the bottle of MEK, the bottle of styrene

putty, and the bottle of Tenax-7R in the aluminum block with

two paintbrushes.

Using two 2” x 6” pieces of lumber, place them in the jig and

glue them to the other pieces with MEK.

MRH-May 2014