frame was also constructed around the door and window at

the time of construction.

In HO scale, a 2’-wide window is almost exactly 1/4”, while

3/8” is just slightly less than 3’, and 1/2” is slightly less than 4’.

The slight discrepancies are of no real concern because all the

windows and doors will be built in the same jig, and thus will

be the same size. No one will ever know that the windows and

doors are not the exact size.

I purchased all of my brass in 0.064” thickness from K & S. The

only size they did not have readily available was 3/8”, which

I purchased from Custom Shapes. I purchased brass in 1/4”,

3/8”, 1/2”, 3/4”, 1”, and 2” widths. The 3/4” width translates

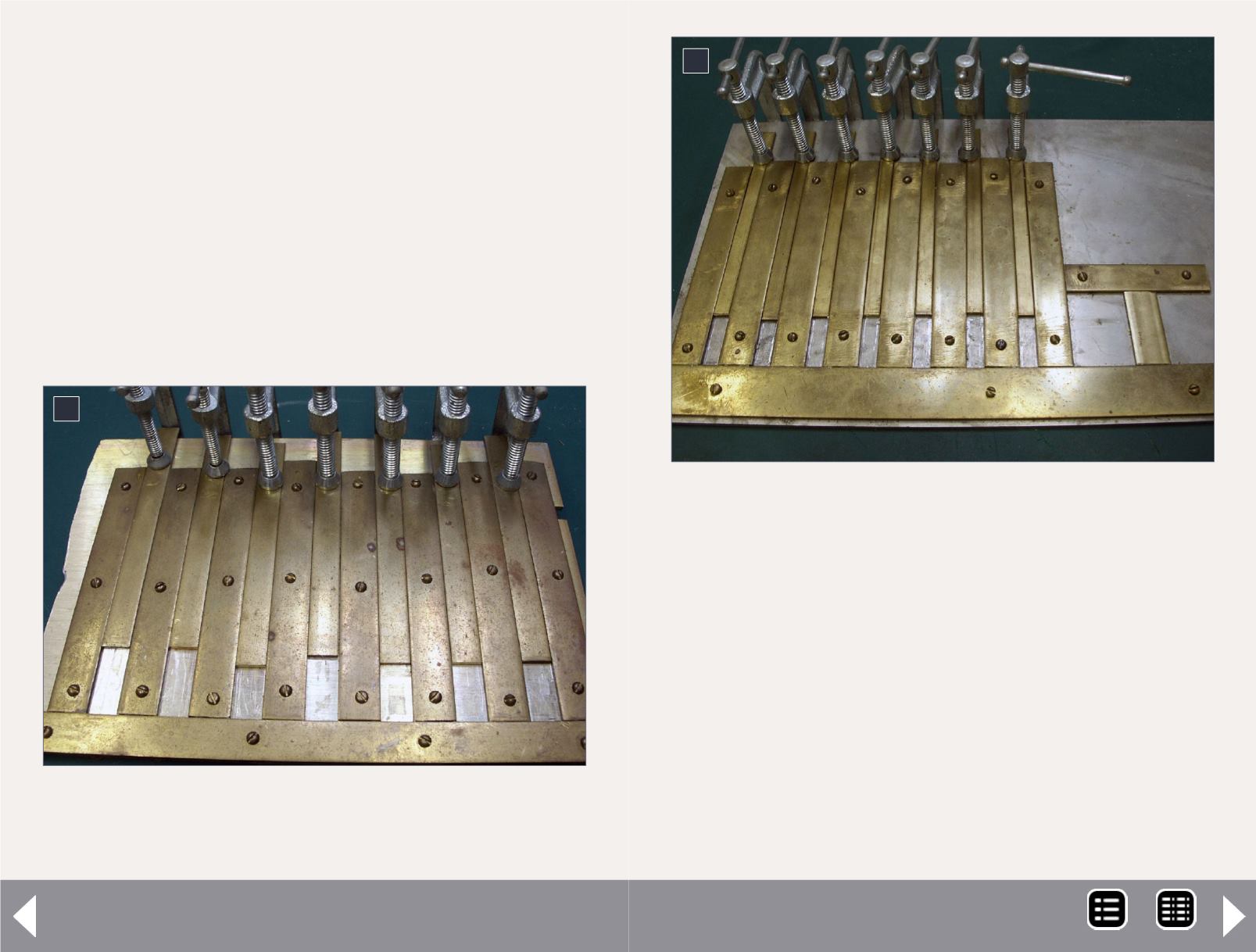

3. This is my 1/2” jig for making 4’ windows or doors. I

can build up to seven windows or doors at a time with

this jig.

3

Windows and doors - 3

4

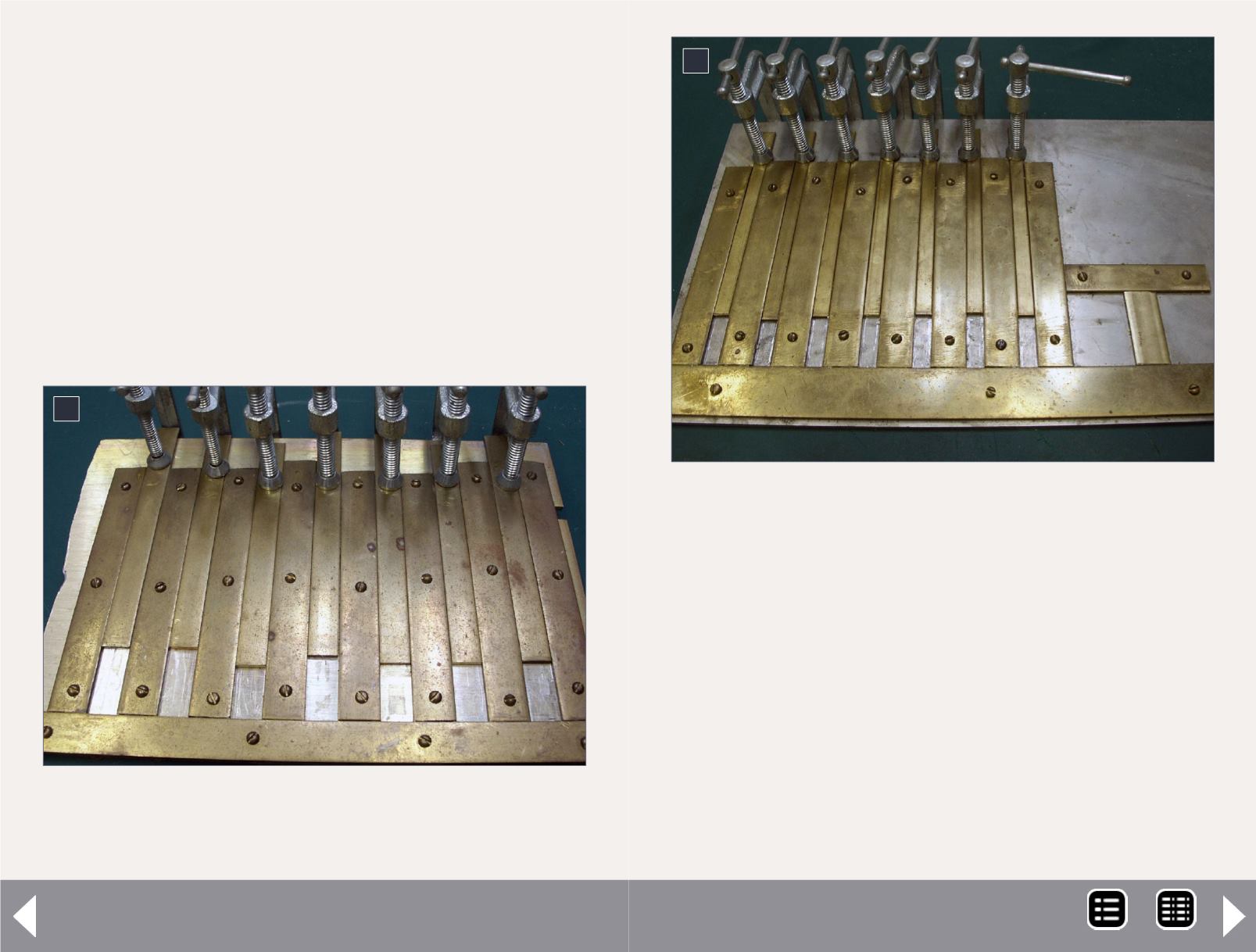

4. This is my 2’ window jig. As with my other jig I can

make up to seven windows at a time. The jigs are

made so that I can adjust the height of the windows as

I need for the structure that I am working on.

into 5-1/2” in HO scale. The 1” width translates into just over 7’

in HO scale. The 2” with piece translates into just under 15’ in

HO scale. If you add together the 1” and the 3/8” pieces they

translate into exactly 10’ in HO scale. The larger width pieces

can be used to make such things as a double, double-hung

window, or perhaps for six double-hung windows next to each

other for use in an interlocking tower. Now I’ll explain how I

construct my jigs.

For the base I use 1/8 “-thick aluminum. These are usually cut

from what is called a rack panel. A rack panel is always 19”

MRH-May 2014