Working the Line

Let’s follow along with the

crew of Iowa Interstate

Train DMSW-12, locally

known as the “Tramp”, as

they work the Grimes Line

and see how they interact

with the locks along the

way. Today’s lineup calls for

the train to work Beisser

Lumber in Grimes, Iowa at

the north end of the line.

Since Beisser is a facing-

point spur, the crew will

have to runaround their

train at Urbandale to place

the cars in the proper

position. Arriving at the

make it functional. Train crews use an uncoupling pick to flip

it open when they need to spot or pull cars during op ses-

sions. Similar to the fence gate method, I set up a wire to

extend up next to the derail, preventing it from being fully

opened. Crews must unlock the derail to allow it to open, just

as on the prototype.

To help orient my operators on which lock controls what, I

added some inexpensive engraved signs above each lock. The

signs feature the spur or industry name, along with its milepost

location. It’s a simple but elegant way to identify each turnout

and lock while showing crews where they are on the layout. It’s

a good idea to label the locks in areas with large amounts of

switches, such as large indus-

tries or a yard, so that your

operators don’t lock or unlock

the wrong device.

When a turnout is no longer

in use, a railroad will usu-

ally spike and tag the switch

to prevent train crews from

operating the turnout. A new

lock will be added to the

switch stand with a tag or sign

indicating that it is out of ser-

vice. I modeled a spiked and

tagged turnout by having the

lock disconnected from the

switch and the throwbar per-

manently secured with piano

wire. I also added a styrene

tag based on the prototype

one behind the lock to show

my operators that the turnout

is not to be used.

Locking up your layout - 9

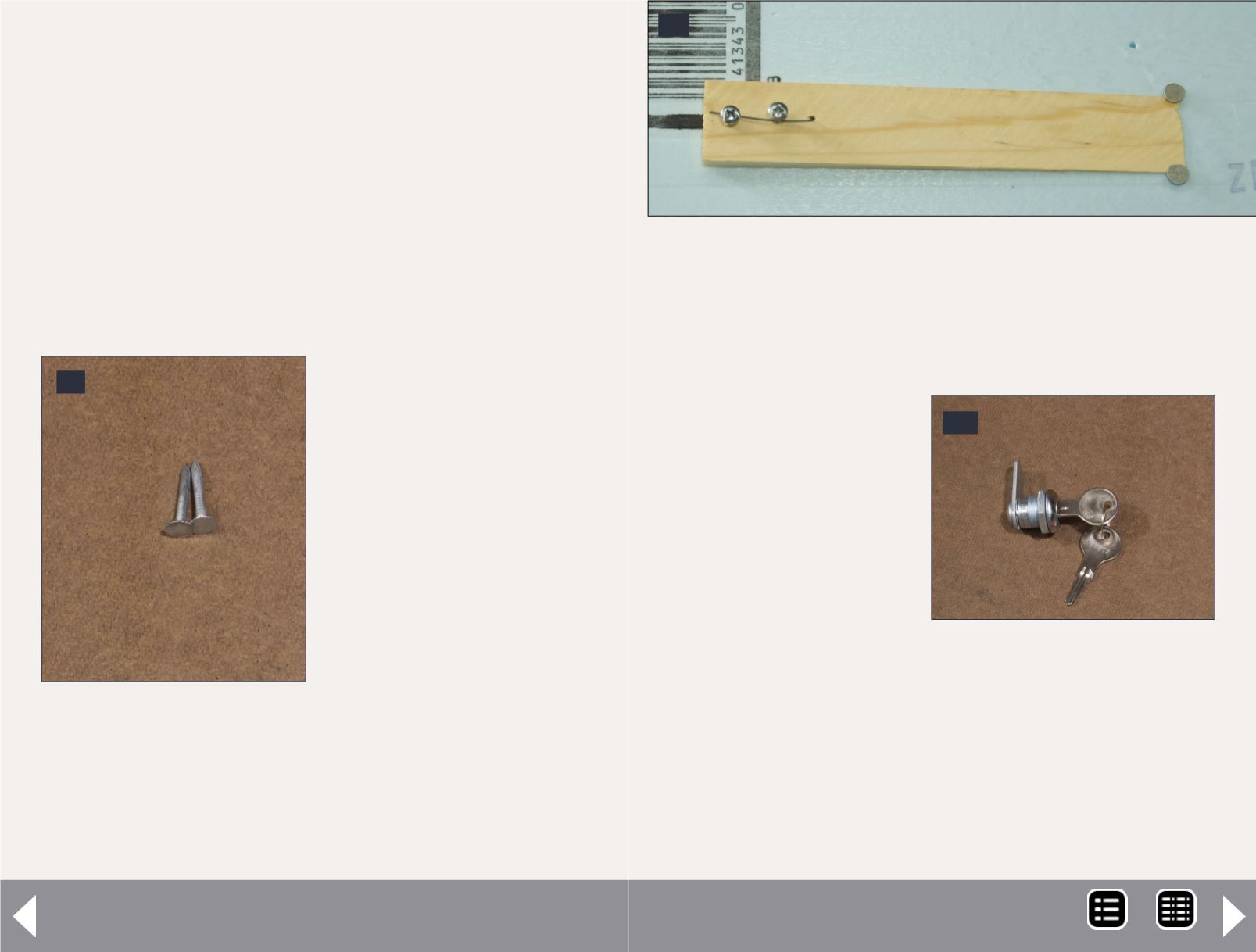

16

16: Roofing nails, with

their short lengths and

wide heads, make great

hinges for the shim wire

setup when using foam

sub-roadbed.

17

17: Make sure the shim wire is installed

perpendicular to the roadbed to prevent it from

binding. Placing the roofing nails on the sides

instead of the ends allows for more flexible

movement of the shim.

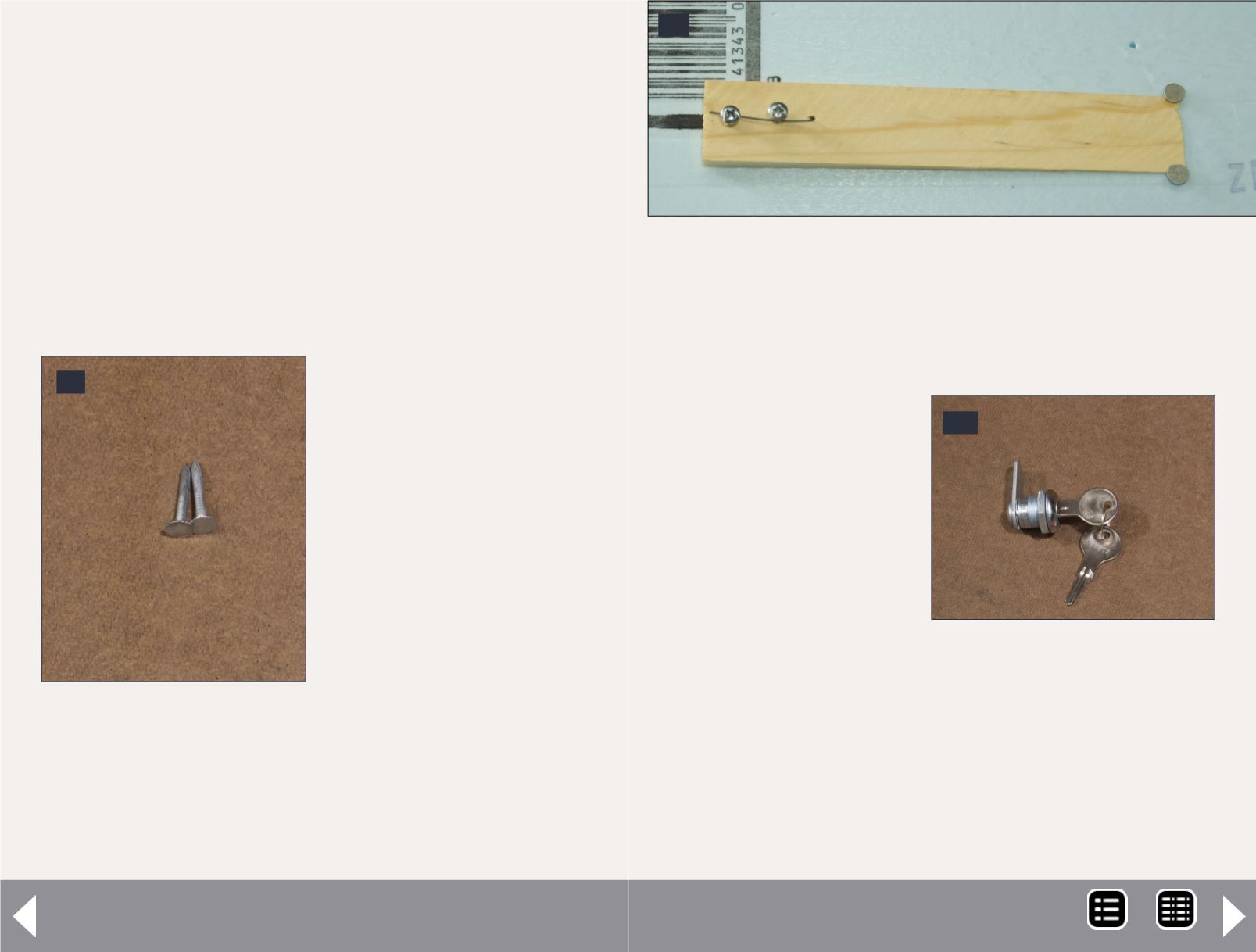

18

18: James used cabinet

cam locks to press

the shim and wire up

against the sub-roadbed.

He preferred the cam

locks because their

flush mounting kept his

fascia clean and clear, as

compared to padlocks.

MRH-Dec 2013