piano wire. The wire is

then bent back under-

neath the shim and

held in place with small

screws. The screws add

additional weight to

the shim.

With the wire attached

to the shim, it’s then

positioned underneath

the layout. I found that

it’s important to make

sure the wire slides

freely through the brass

sleeve. If it binds, the

wire won’t drop down

when released. Make

sure that the wire and

shim combo are per-

pendicular to the sleeve

and roadbed when

installing them.

Fighting Gravity

The wire was now

free to drop into the

unlocked position, but I

needed a way to prevent it from dropping down to the floor. I

only needed the wire to drop enough to clear the throwbar, a

distance of less than an inch.

First, I needed a way to attach the shim and wire combo to the

underside of the layout, but still allow it to move freely. Luckily,

I use extruded foam as my sub-roadbed. Some short but thick

roofing nails give me the leverage I need to act as a hinge on

Locking up your layout - 6

the same diameter as the wire to allow it to fit snugly when

locked, then trimmed the wire flush with the top of the throw-

bar. To stiffen the wire and make sure it wouldn’t wiggle loose

in my extruded foam sub-roadbed, I use a brass tube as a

sleeve around the wire. The tube also reduces friction as the

wire moves through the roadbed.

With the wire in

place, I needed

a way to lift and

remove the wire to

lock and unlock the

turnout. I decided

I wanted the wire

to default to the

down, or unlocked,

position. That

way if there was

a mechanical fail-

ure, I could easily

unlock the turnout

without affecting

its operation. By

itself, the wire is

not heavy enough

to drop down on

its own. I devised

a way to use a sim-

ple wooden shim

to add additional

weight to the wire.

A hole is drilled

through the thicker

end of the shim to

feed through the

10

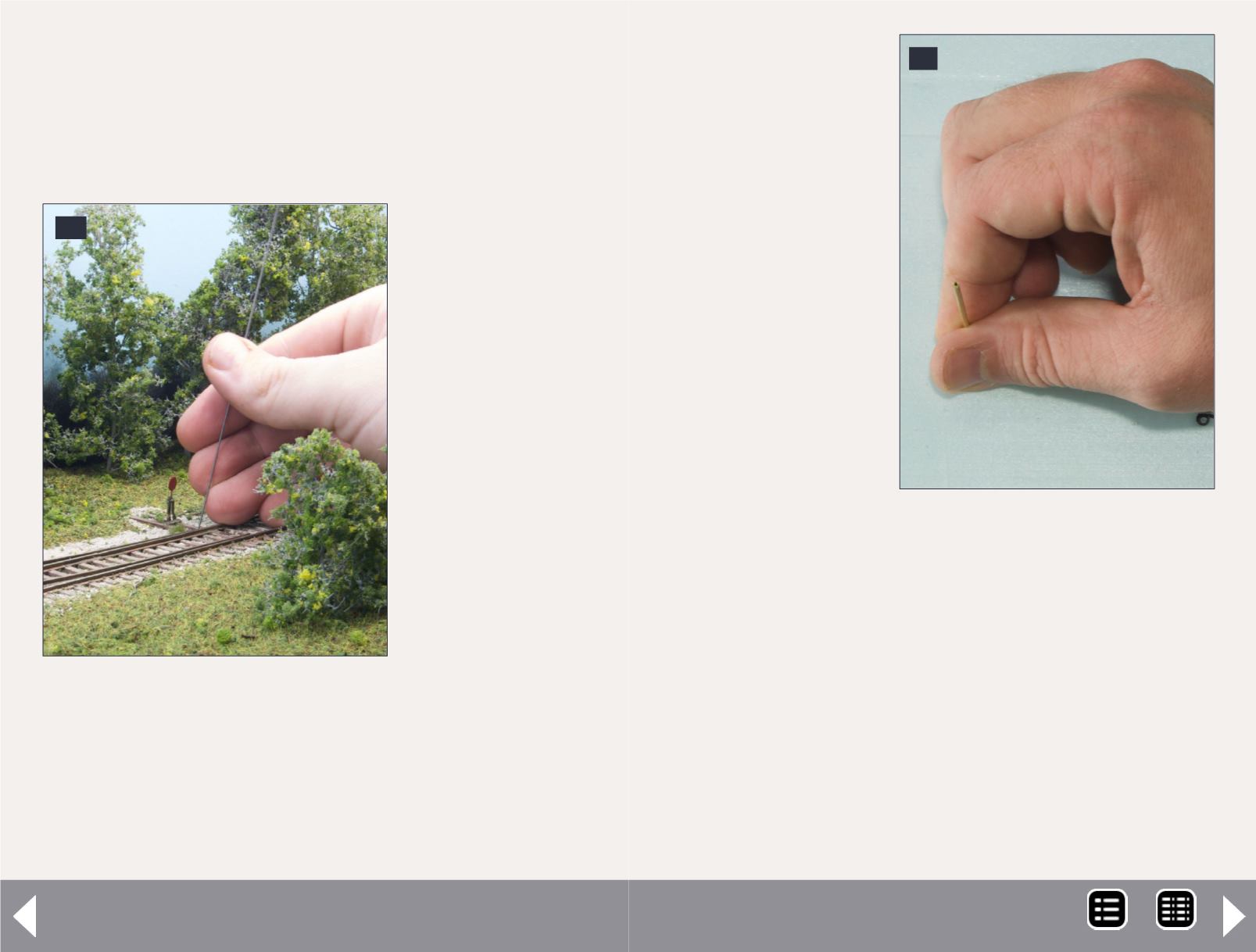

10: Stiff but thin piano wire

is then threaded through the

throwbar hole and into the sub-

roadbed. James uses extruded

foam so he doesn’t have to drill

through a plywood base to pass

the wire through.

11

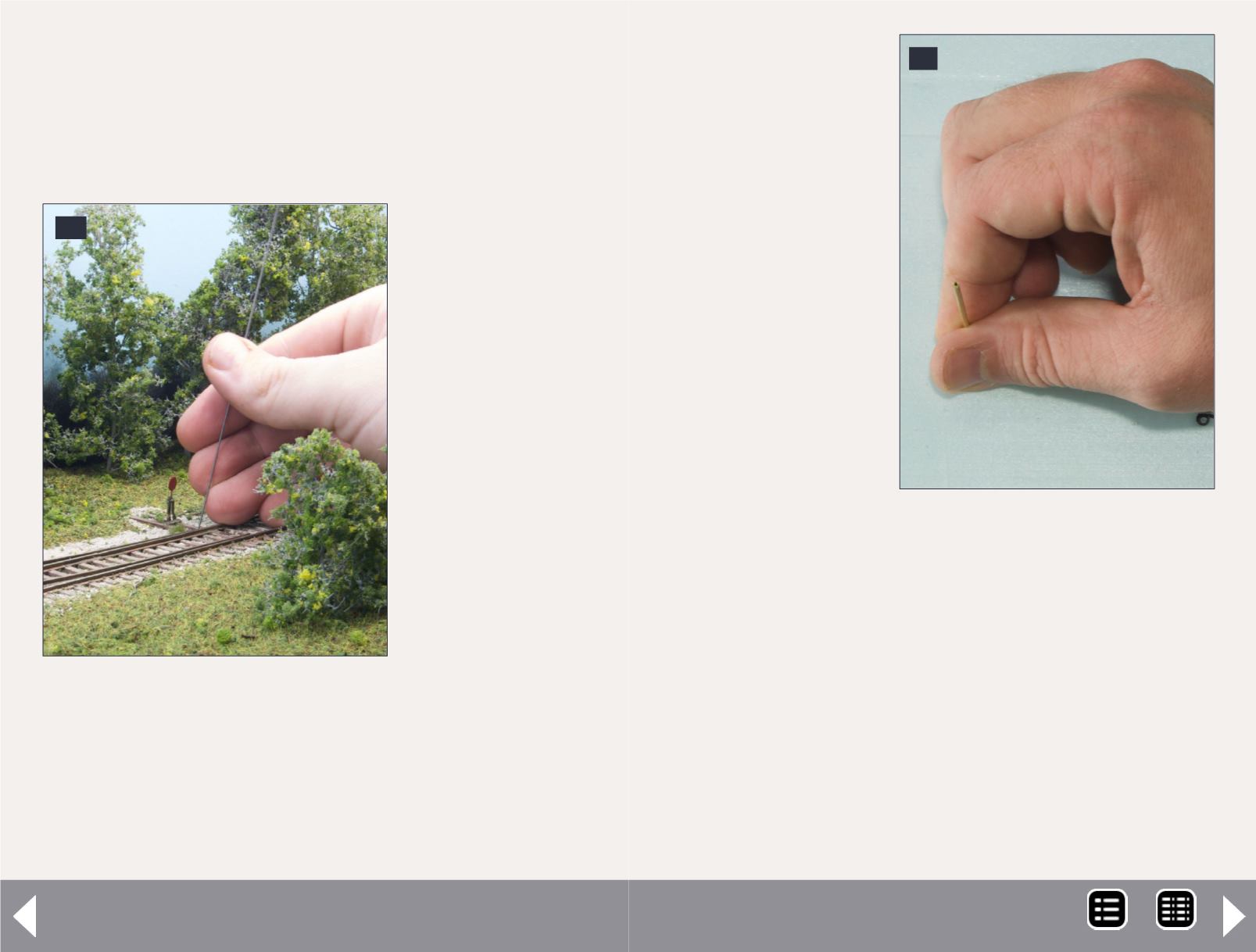

11: The wire is threaded

through a brass tube to stiffen

it in the sub-roadbed and

prevent it from moving around

in the foam.

MRH-Dec 2013