MRH:

I’ve been impressed with your fabrication facility. Tell the

readers why you are so committed to in-house manufacturing.

ST:

We believe that we can and should do it in the U.S.A. It is

all about quality and service. We can completely control the

manufacturing process, which is key to our quality control.

We also control our delivery – pretty much guaranteeing that

we will have product available when our customers need it.

We have seen what happens to companies that manufacture

overseas – product is late shipping, pricing is not within their

control, and quality is average at best.

With the closing of so many factories over the past twenty

years, the subject of how we are able to successfully

manufacture our products in the U.S.A. is frequently

broached. We invest regularly in quality capital equipment.

Our SMT (Surface Mount Technology) machines are fast and

efficient, and continually upgraded and improved. In the past

six months, we have added two new pieces of production

equipment. This is just part of our commitment to continually

improving our processes while keeping a stable workforce.

Adding some automation does not take away jobs! In fact, it

offers opportunities for some of our employees to ‘specialize’

in the operation and maintenance of these unique pieces of

equipment, keeping what could otherwise become a routine job

a tad more interesting.

Making our electronics in the U.S.A. allows us to completely

control our production – time to delivery, cost and quality.

Automating some of the manufacturing allows us to offer

competitive wages to

our employees. Parts

procurement and pricing is

more controlled. We don’t

DCC Impulses Column - 4

suffer the delays and expense of having our product shipped

from outside the country. It is our intent to continue the design

and manufacture of our electronic products in the U.S.A.

Of course, the subject of Blackstone Models comes up as well.

We design them here but, at present, can only economically

produce them in China. Nobody would be happier than we to

manufacture these products here. Watching wages overseas

rising, customers are often under the impression that we could

now successfully bring this manufacturing on shore. The labor

rate in China has increased from $0.90 per hour to $2.00 per

hour. It is still a fraction of the domestic minimum wage of

$7.50/hr. There are so many manual assembly processes in the

making of a model that we can’t assemble it here and deliver it

at a cost that the market wants.

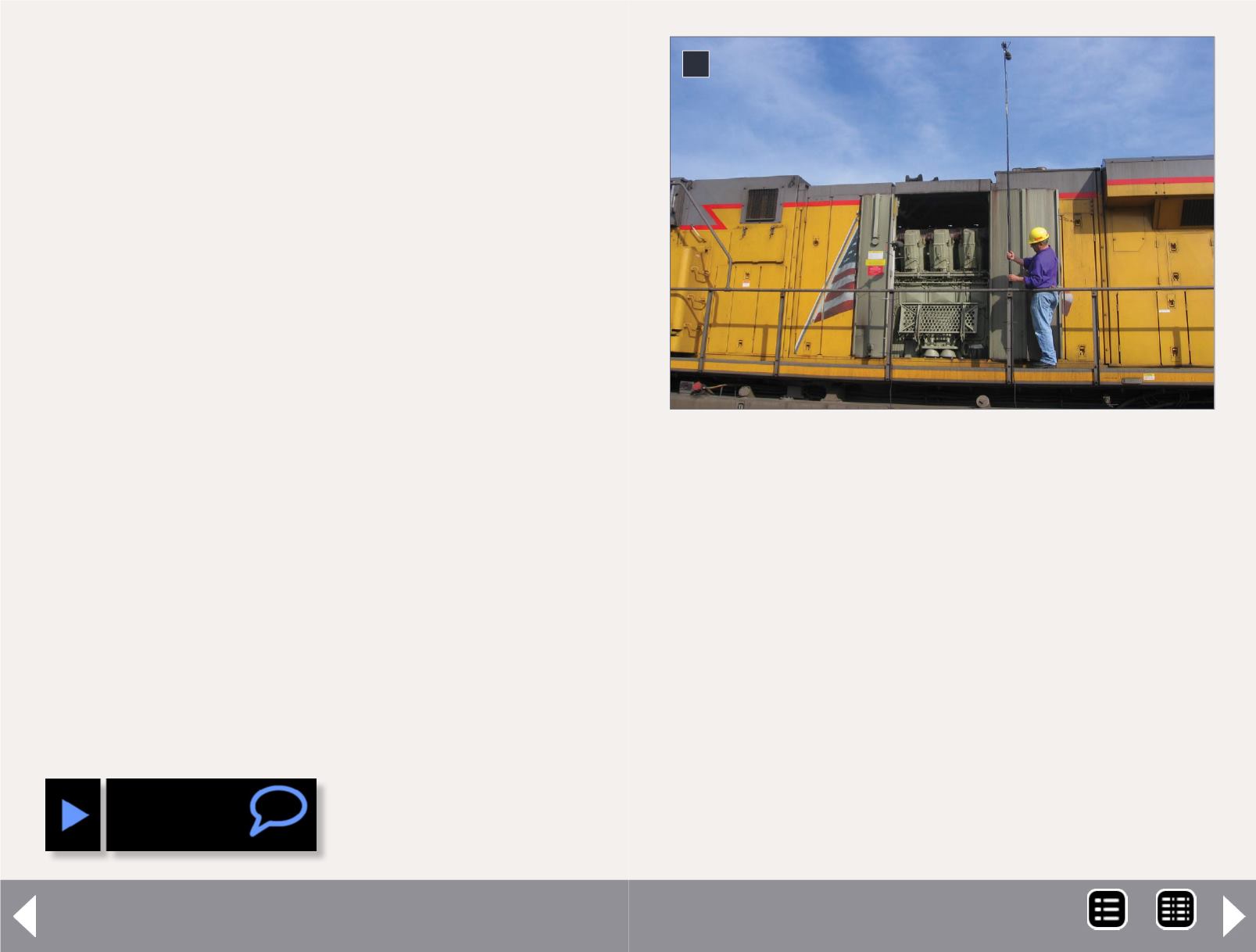

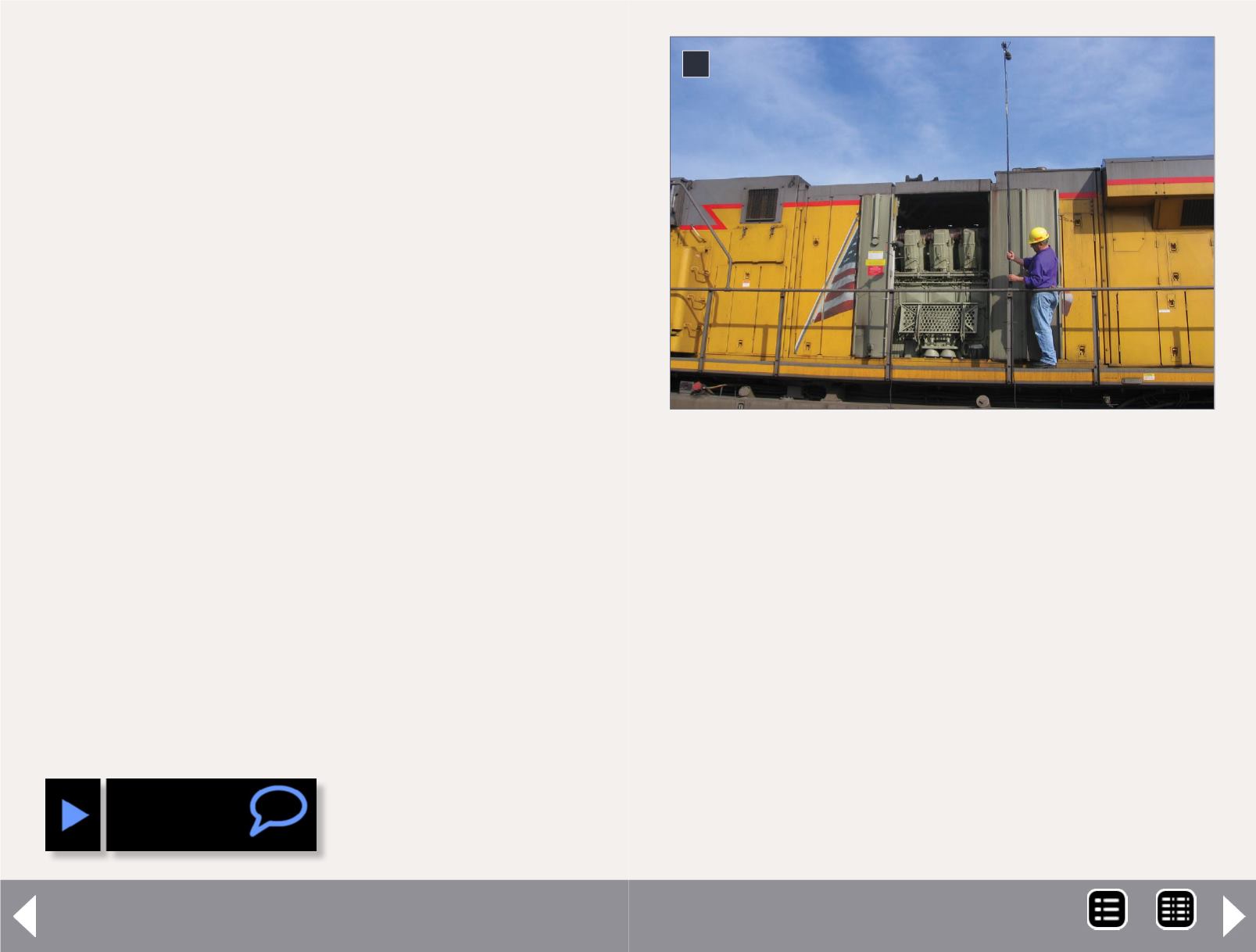

4: SoundTraxx’ personnel recording a diesel loco on site

4

MRH-Oct 2013