Animated icing platform - 3

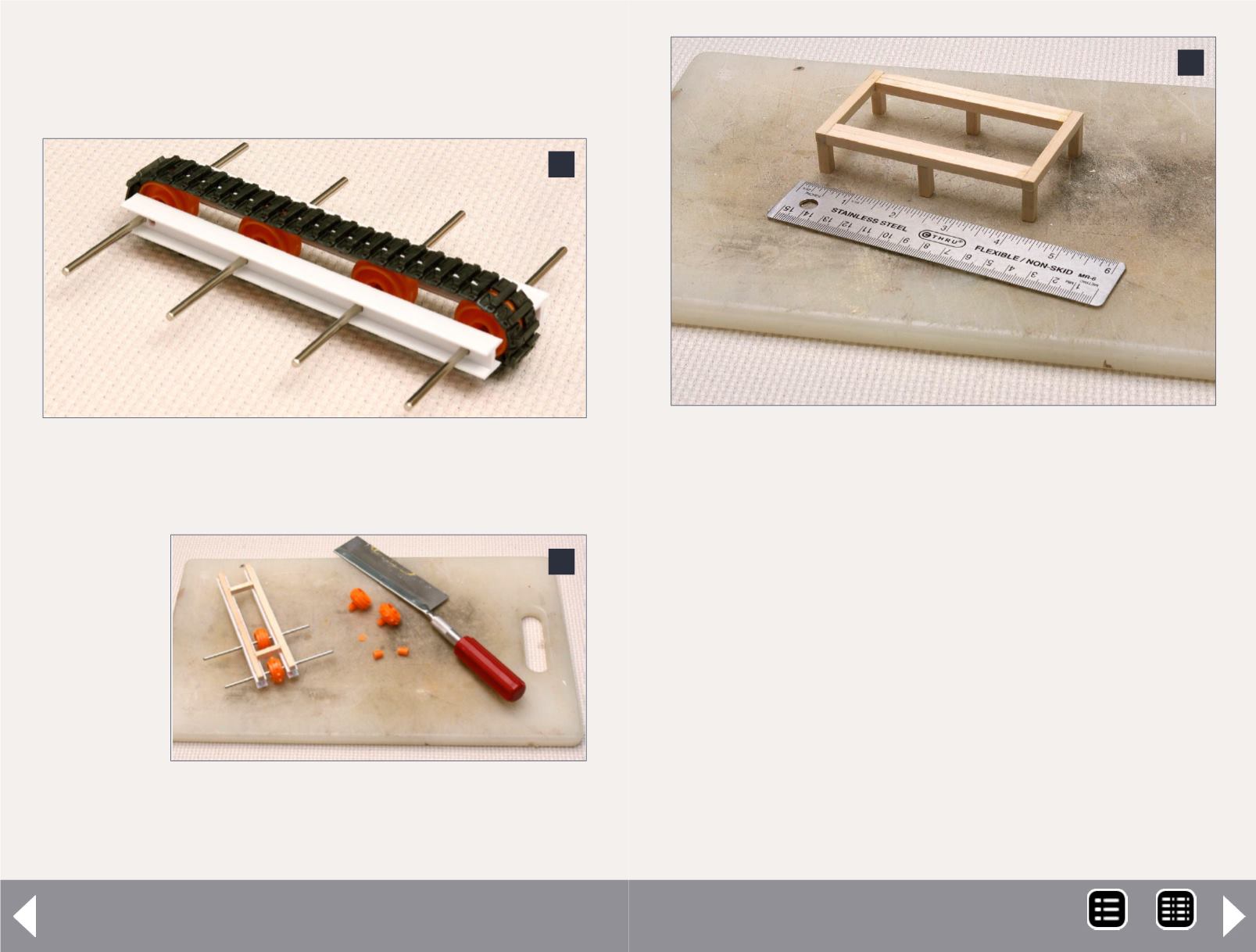

sprocketed end wheels for the drive and smooth inner wheels

for conveyor support. I determined that the tread was stretched

appropriately when the outermost axles were 4-7/8” apart (5).

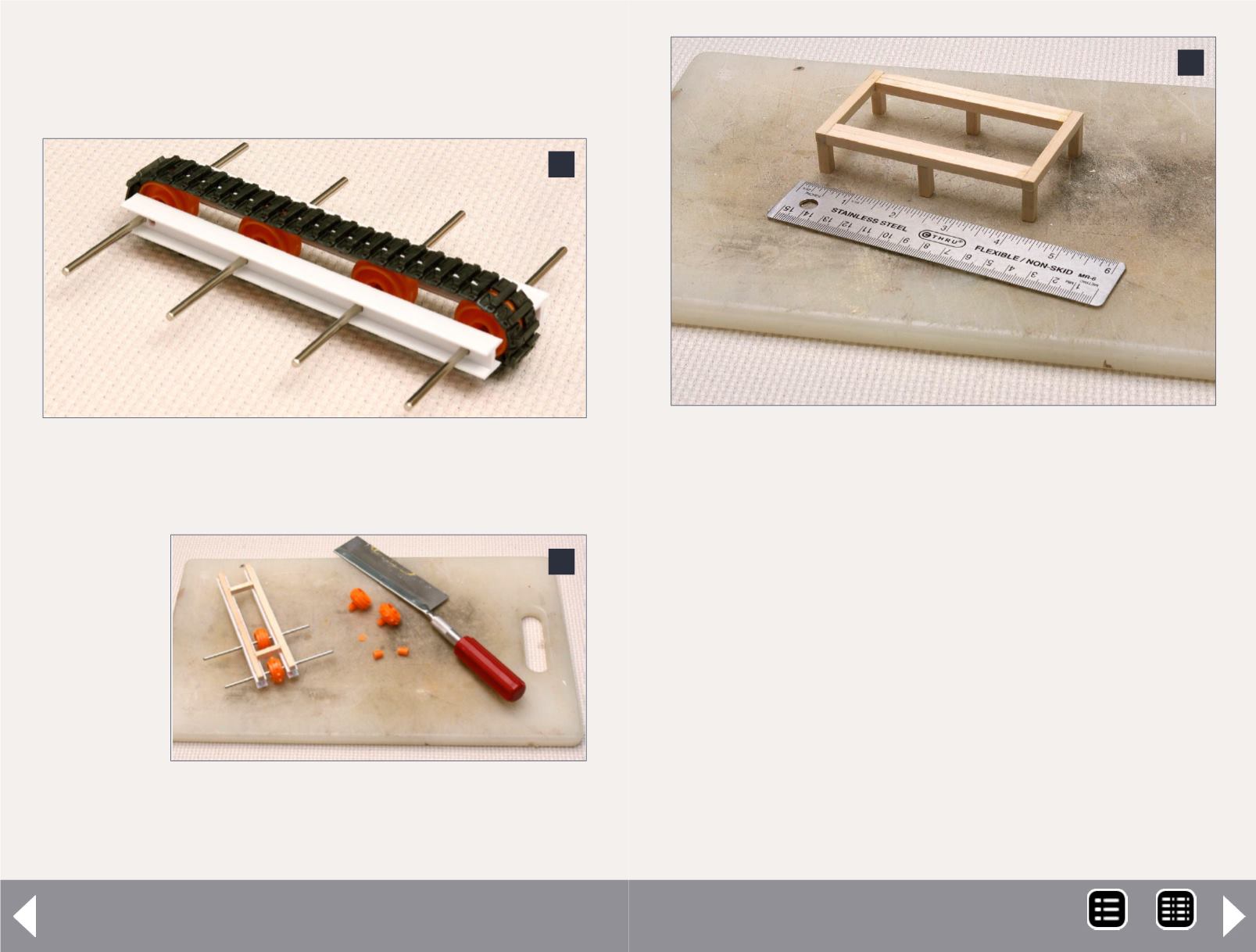

I then created a simple frame from square basswood (10” x 10”

scale) to hold the H-beams 1” apart, measured between their

innermost edges, and trimmed extensions on the Tamiya wheels

to fit (6).

I created a simple frame from square basswood to hold the

H-beams one inch apart measured between their innermost

edges. I then trimmed the extensions on the Tamiya wheels

to fit.

I made a simple 2-¼” x 4-½” lower platform structure to hold

the conveyor belt (7). Next I glued 1/8” x 3/8” slats, leaving

a center hole for the conveyor. The conveyor is attached to

the platform by the axle running from the motor through the

wooden frame and an end hole in the H-beams. I also glued

5: The partially completed conveyor system. The holes

drilled in the H beam need to be square with each

other so that the conveyor will track properly.

5

6: I built

a wood

frame from

10” x 10”

O scale

bass that I attached to the H beams to maintain the

proper spacing. You can also see the extensions that

are trimmed from each of the Tamiya wheels.

6

7: The base of the simple platform I made to house the

bottom end of the conveyor.

7

MRH-Aug 2013