STEP 12: Detailing the Sides and Ends

Continued ...

50

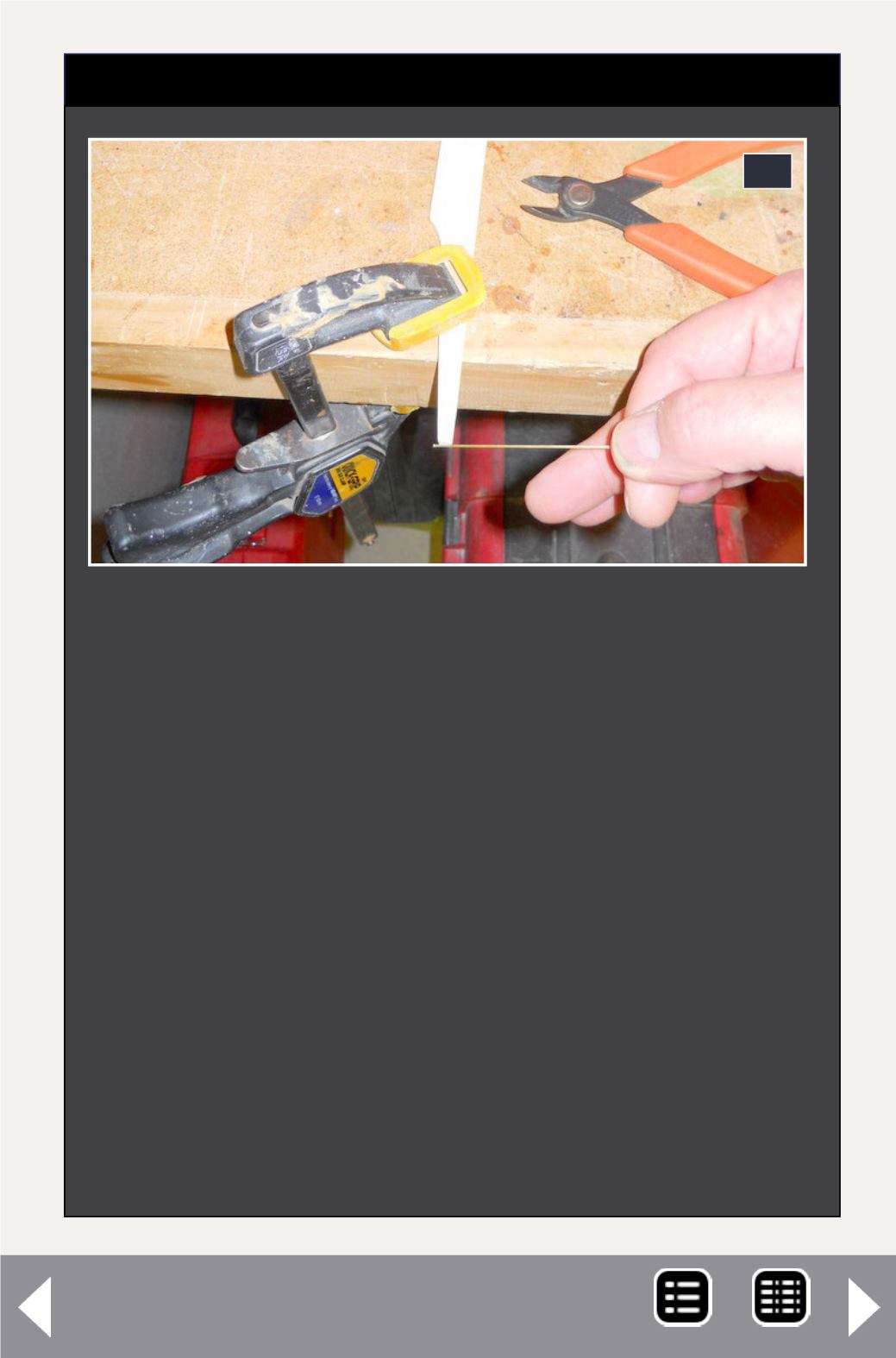

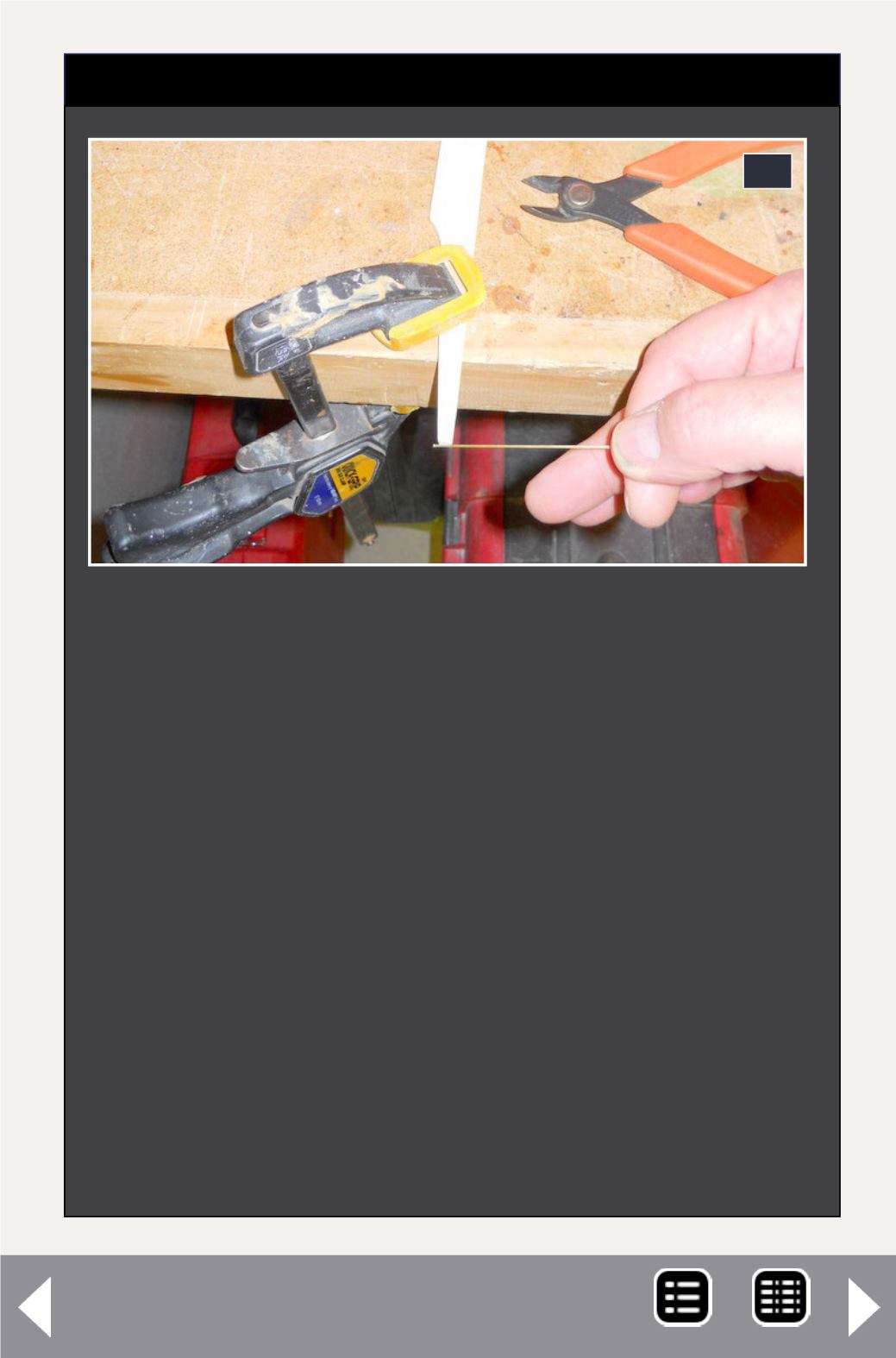

50: I have a homemade jig that I use for bending

wire for grab irons. The jig is made of two pieces

of .060" plain styrene were cut to 5-1/2” long by

3/4” wide. At one end I made a taper from 3/16”

(HO scale 16”) to 1/2” (HO scale 3’-10”), and

this taper is 3” long. A hole was drilled so I could

hang it on a peg at my workbench. A piece of

.020" freight car siding was cemented to one side

of the jig. I then filed the pieces to create a nice

smooth surface along the sides.

With the taper I can bend a variety of grab irons.

The car siding provides the locating marks to

ensure the proper length of the grab iron. To make

sure that I use the proper mark for each grab iron,

I put a piece of masking tape next to the desired

width. Tape was not needed on this project, since I

used the smallest grab irons.