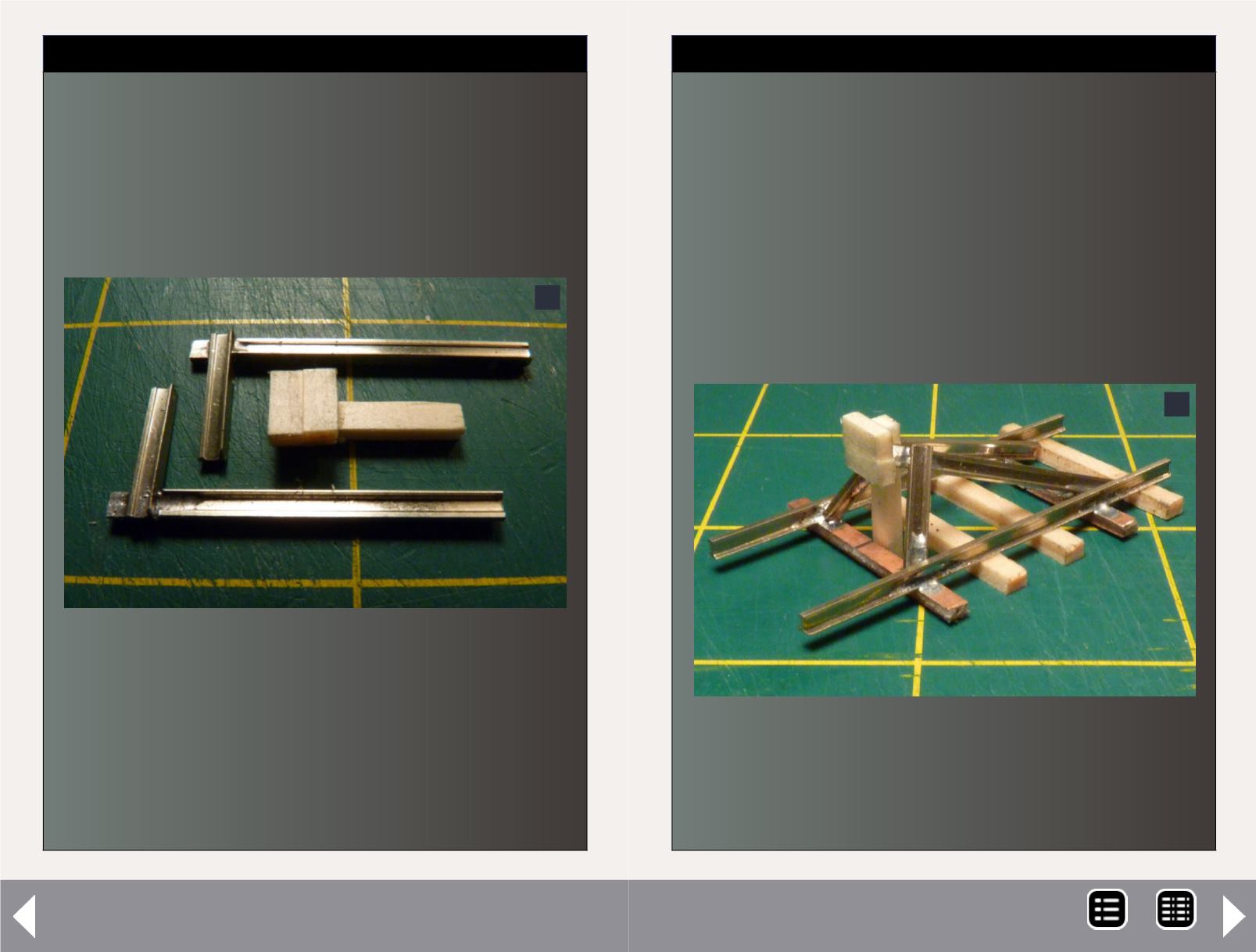

3: These are the three sub-assemblies required to

make the bumper.

STEP 3:

I then assemble the components. I solder the 1-1/4" and

1/2" rail pieces at 90⁰ angles to each other, making mir-

ror pieces. I wire-brush any solder residue from the rails.

I glue (using fast setting CA) the two 1/4" wood tie pieces

next to each other to form 1/4" wide pad, two ties high.

When dry, I glue the pad to the top of the 5/8" wood tie

which becomes an upright support for the pad.

3

Scratchbuilding a Code 83 Rail Bumper - 3

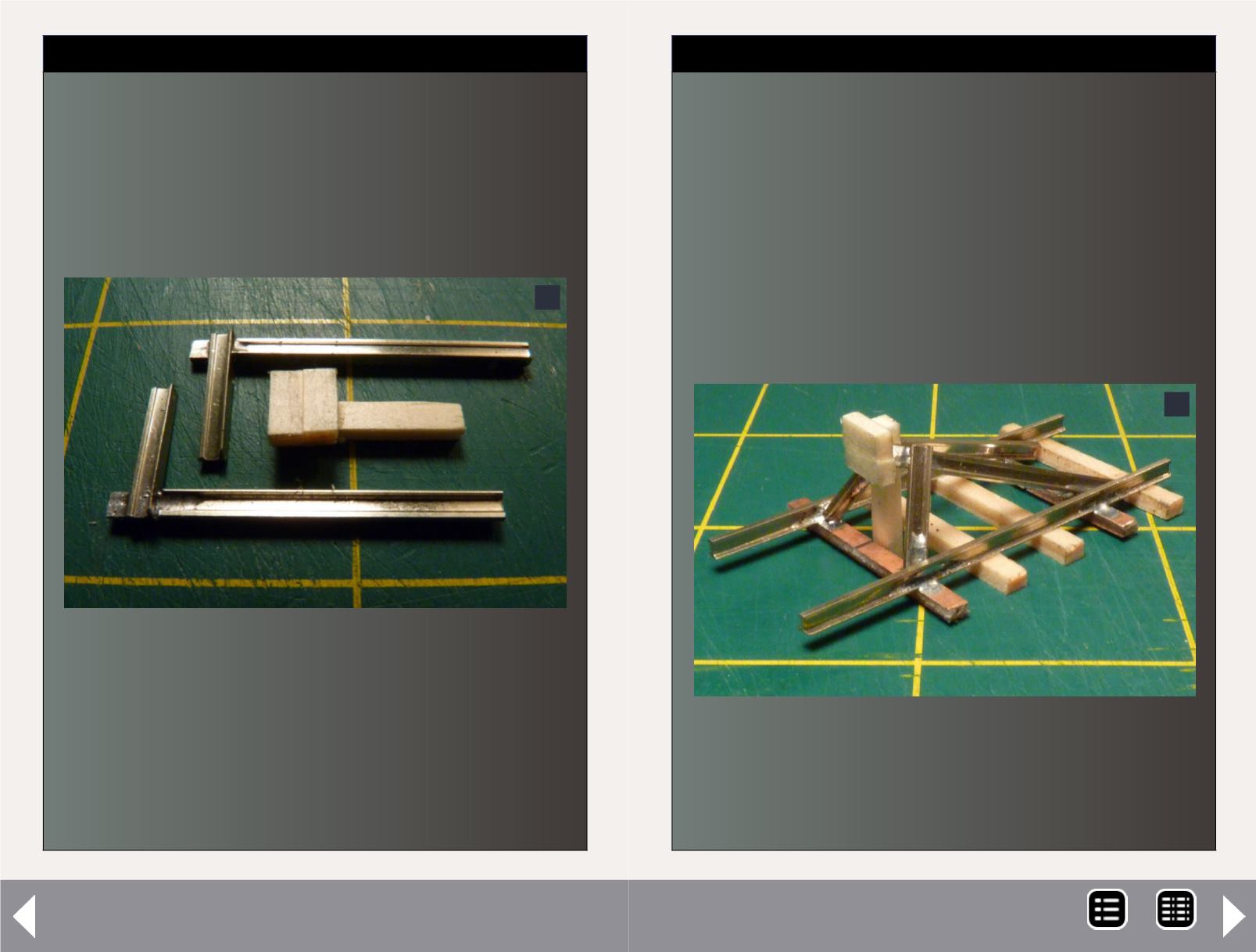

4: This is the completed bumper ready for

installation.

STEP 4:

Now, I glue the bottom of the upright pad support to the

side of one PCB ties facing the middle of track section.

When the glue dries, I lean each 900 rail piece onto oppo-

site sides of the top of the upright pad support behind the

pad. The end of the 1/2" rail piece should rest on the PCB

tie and the end of 1-1/4" rail piece should drop between

the other PCB tie and the last wood tie. Make sure the

ends of the 900 rail pieces are touching the inside of stock

rails. Touch top of 90⁰ rail pieces with a drop of glue, and

wait to dry. Then solder the ends of the 90⁰ rail pieces to

inside of the stock rails

4

MRH-Jun 2013