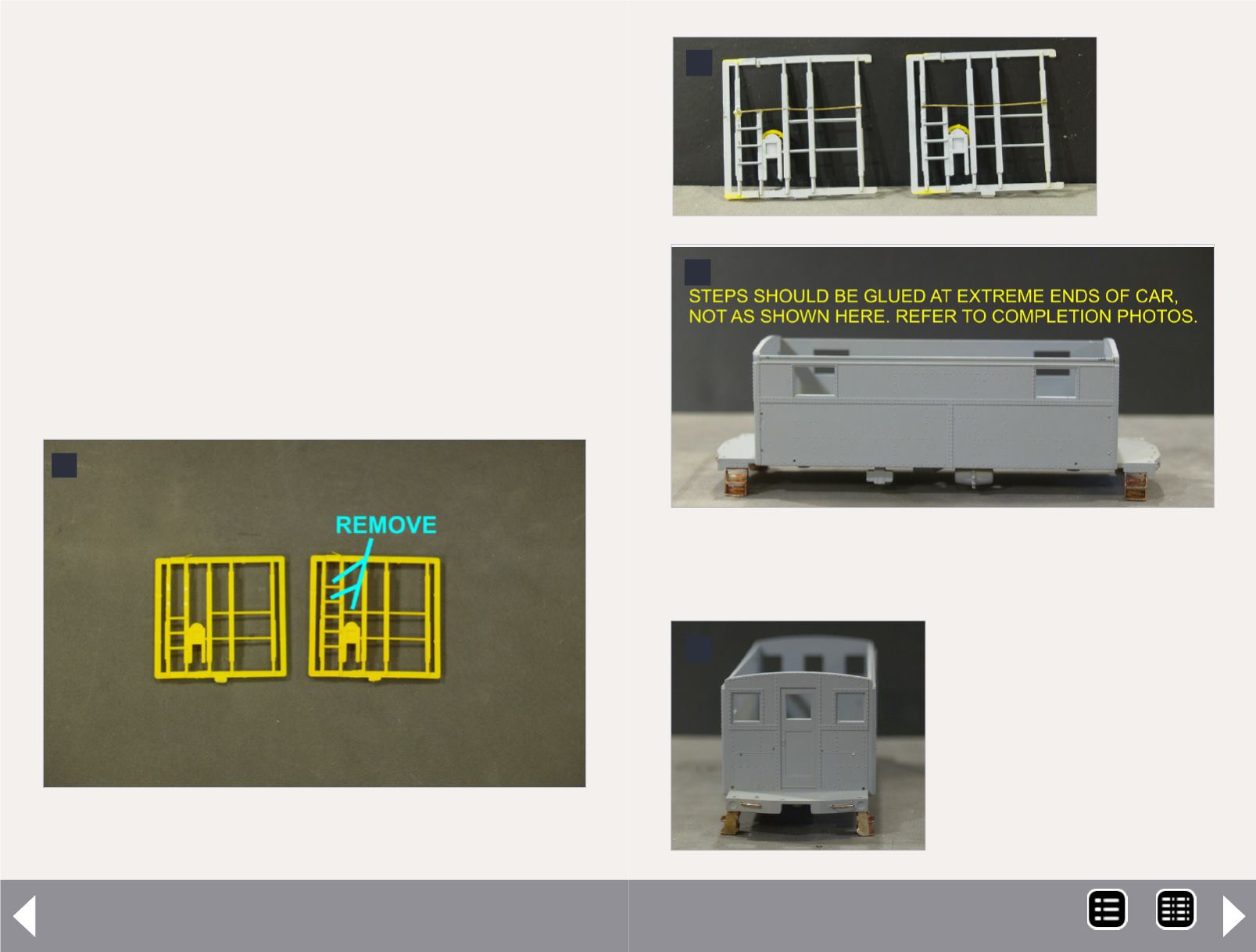

5. Do as I say, not as I do. As indicated, the steps

should have been glued to the ends of the car.

Otherwise, there will be clearance issues with the

Atlas Caboose Trucks.

Also, body is pre-drilled for

grab irons.

6. An end view, showing

the pre-drilled holes for

grab irons and installed

end sill grab irons.

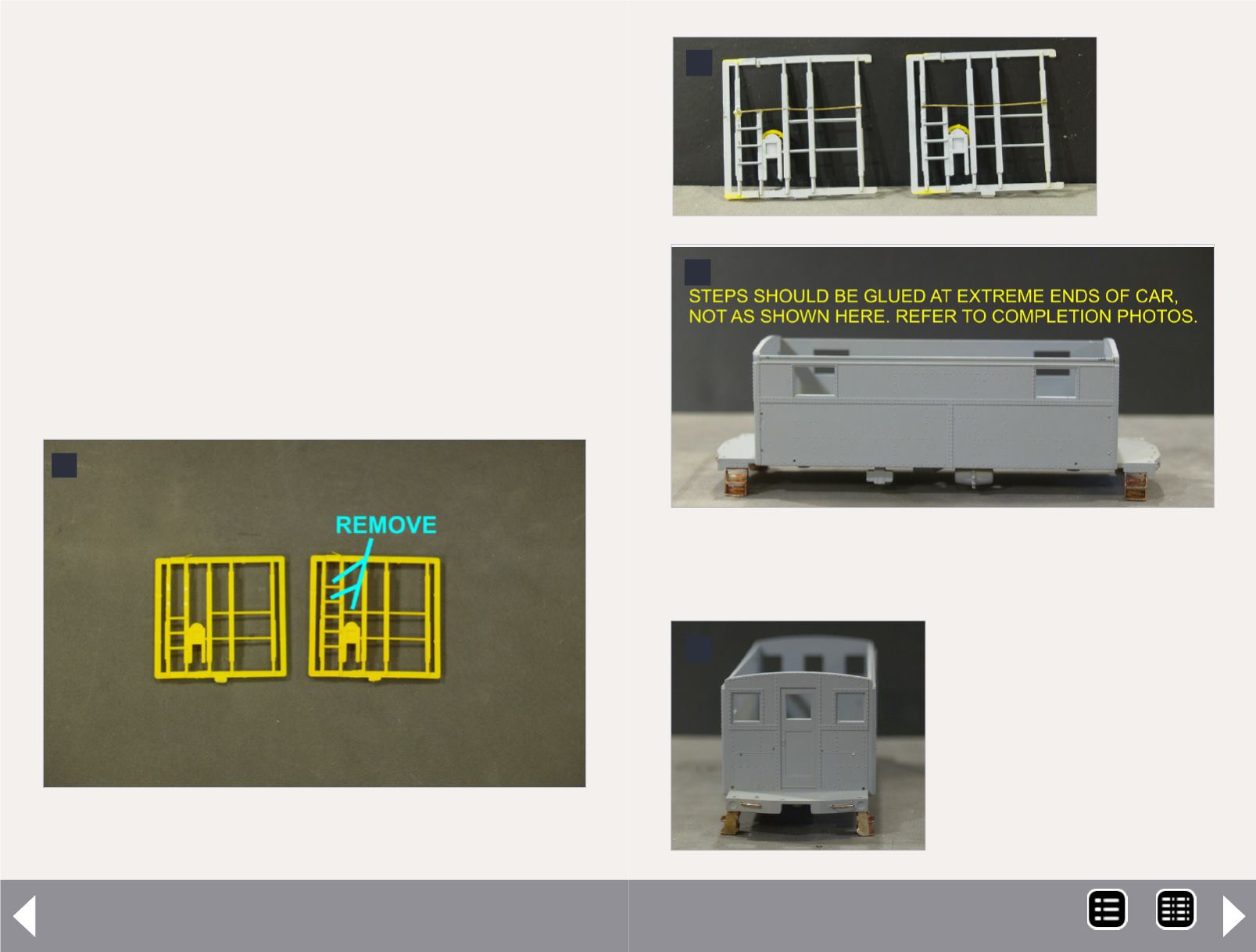

this caboose is having modifications done to represent it

after its rebuild with replaced trucks, I used Cal Scale #475

(Pennsylvania Railroad Caboose Steps), which replaced the

original steps, and were moved outward to allow space for

the new trucks. A note of caution: despite the casting hav-

ing two pins spaced at the same distance as the body-molded

holes for the original steps, DO NOT use these holes. The

steps must be glued at the extreme ends of the caboose to

obtain the correct spacing for the new trucks, just like the

prototype did. (I found this out the hard way.) This completes

the body modifications (5-6).

Now that all the major component modifications have taken

place, it’s time to paint and letter the caboose, I airbrush using

Floquil Railroad Enamel products. I first primed all parts to

3

3. This shows the removed portions of the ladder and

grab bar.

Modeling Conrail’s EX-PC/PRR N5 Caboose Fleet - 3

4

5

6

4. The

added

wire grab

across

the full

width of

the ends.

MRH-Feb 2013