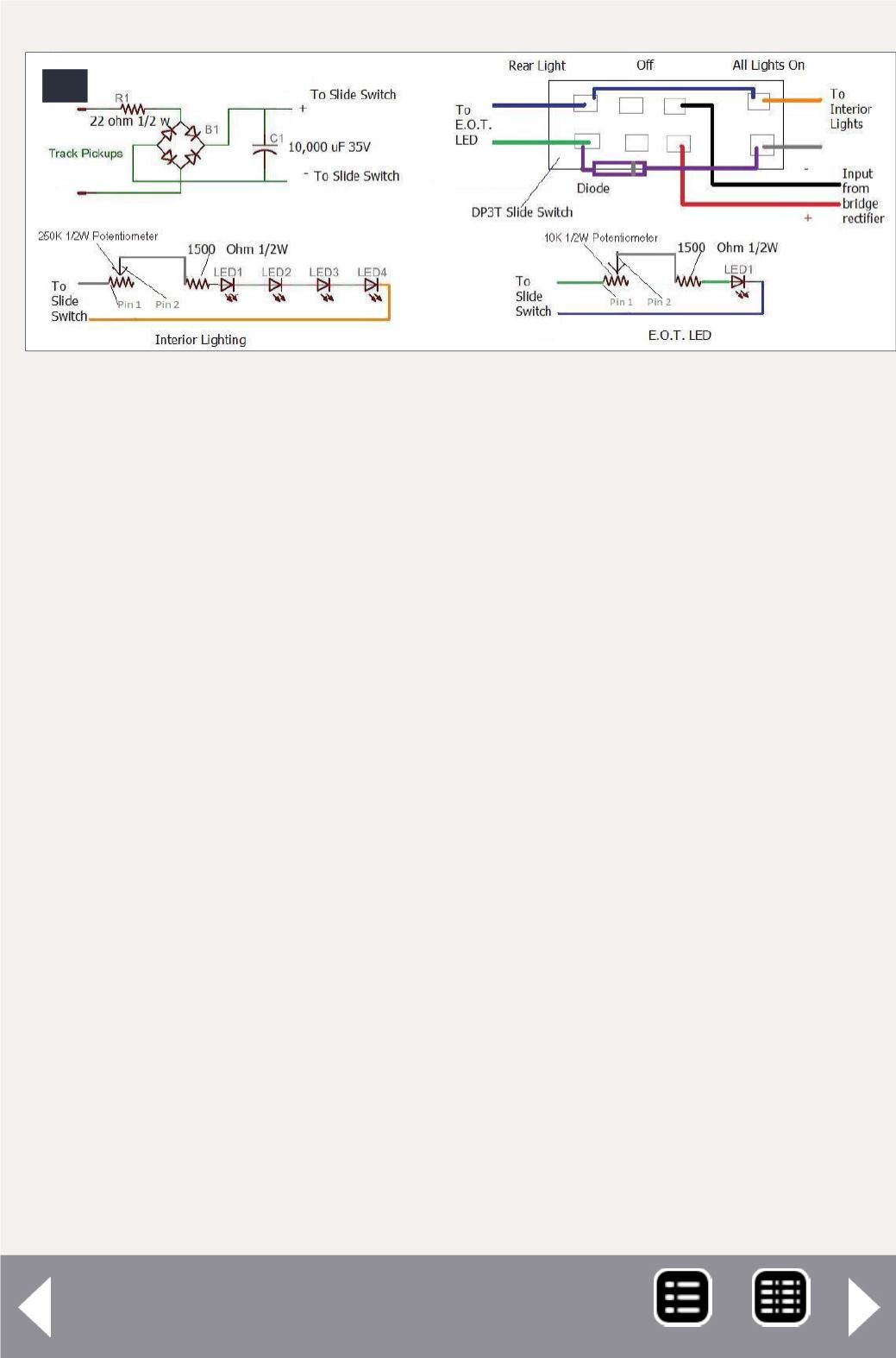

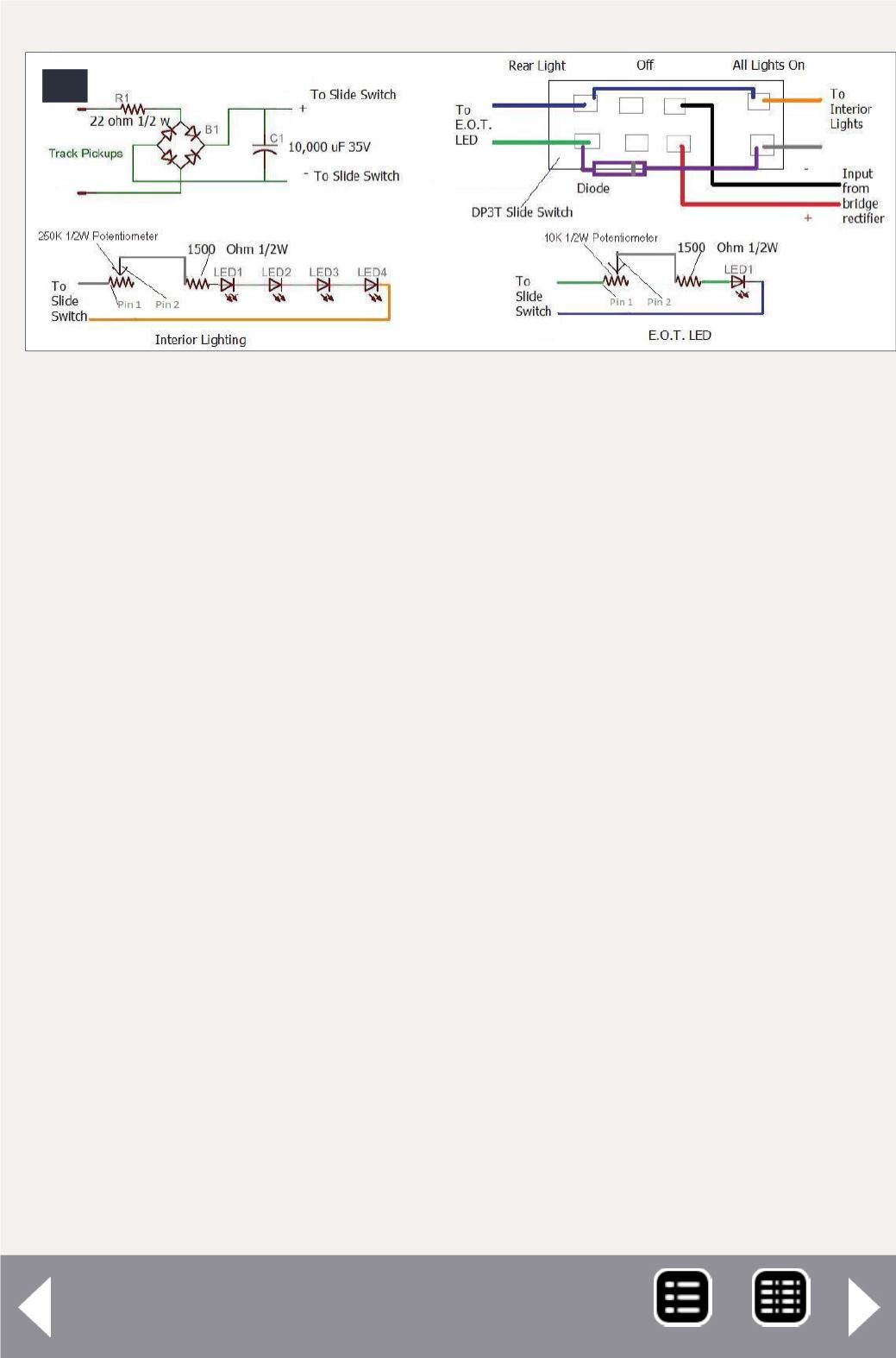

see [17] and [18]. The capacitor is also wired to the same tabs

on the slide switch as the positive/negative power inputs. I

wanted a capacitor large enough to keep the LEDs from flicker-

ing due to dirty track. I put in a 10,000 µF 35v capacitor. Some

say this is fine, others say overkill. For me, it’s doing the job I

want it to do. Running over semi-dirty track has resulted in no

flickering. From what I’ve read, 2,200 µF through 10,000 µF

will keep lights from flickering, but it all depends on how much

interior space you have to work with.

Electrical power is carried to the roof by metal tabs that run up

the side in each corner. I soldered a negative wire to one tab at

each end, and did the same thing for the positive wire. If you

look at the upper-left corner of [19] you’ll see the conductor’s

table I added. I used an N scale building door light as a desk

lamp. It seemed to be the right size at first, but now I’m won-

dering if an HO scale lamp would have been better. [20] shows

the conductor’s desk before being glued into place.

18. Here I added in potentiometers to control the

brightness for the interior lights and the EOT light. The

resistors near the LEDs prevent damage to them if the

potentiometer is turned all the way down.

18