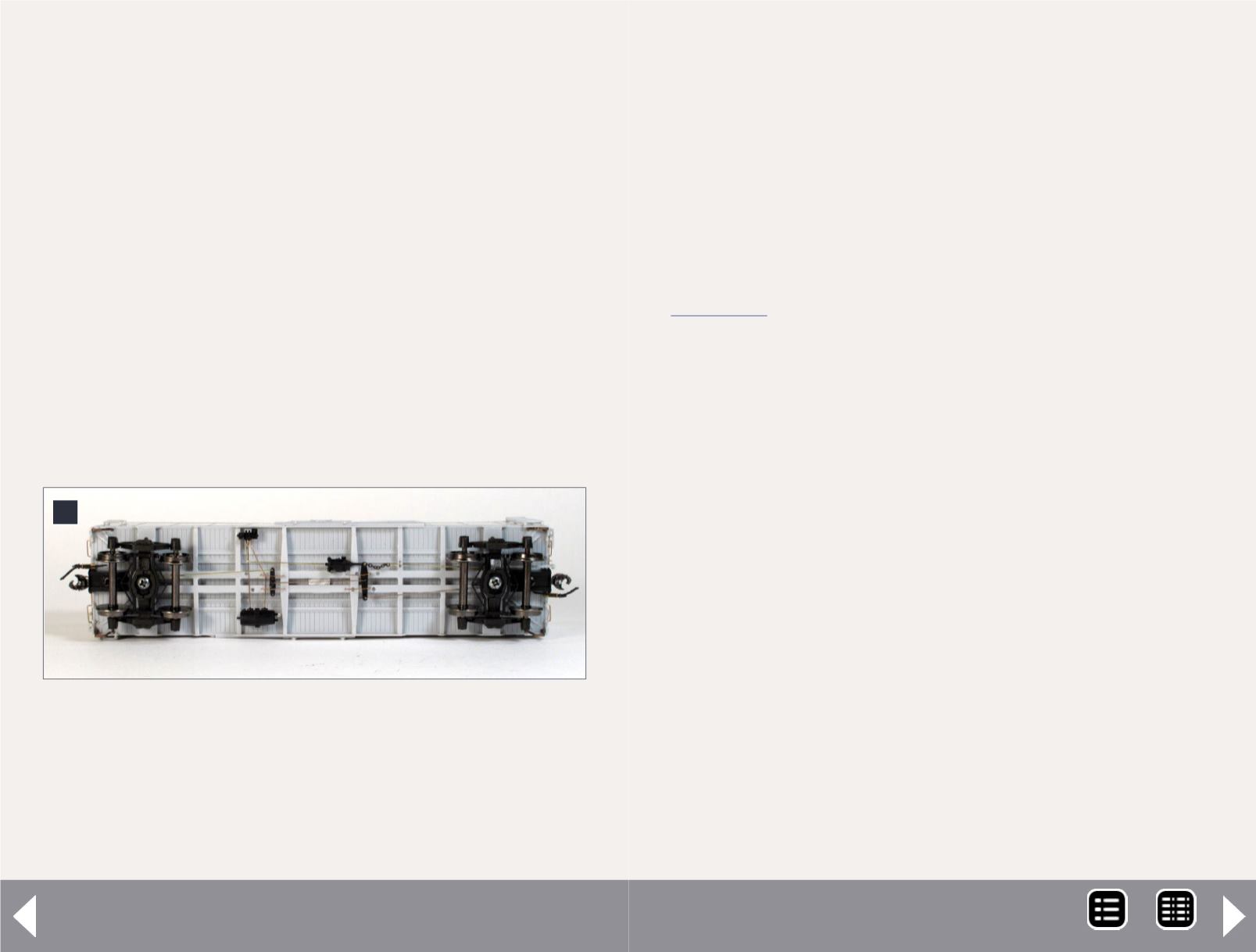

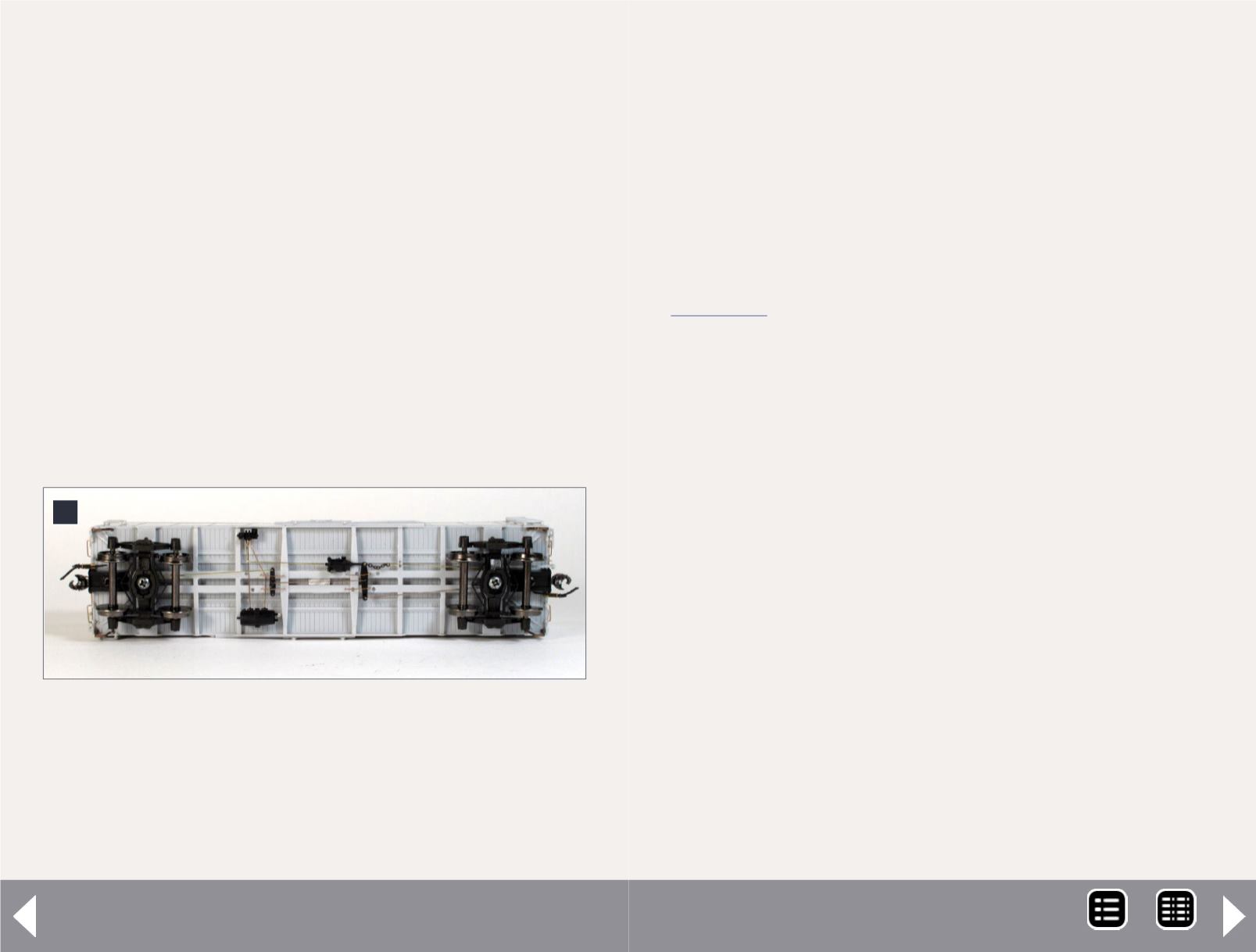

wheel and brake gear. The left and right sides of the car are

identified as the left and right sides of the car when the viewer

is facing the B end. No matter which way you look at the car,

there is always a clearly defined A end, B end, left side and

right side of the car.

I assembled the underframe per the car’s instructions but dis-

carded the brake gear sprue and used a Cal Scale No. 294 brake

gear and set and Tichy .010” wire. I consulted prototype pho-

tos to ensure I mounted the reservoir, AB valve and cylinder in

the correct places. I omitted the train line. I used a short sec-

tion of Builders-In-Scale No. 252 chain to attach the cylinder

and the brake rod.

I took great care to ensure that no gear was hanging in a man-

ner that would interfere with the model’s operation on my lay-

out. I filed down the injection molding post in the center of the

car to make the underframe fit. I discarded the plastic coupler

boxes included with the kit and substituted Kadee No. 178

scale couplers, which I glued in place and then screwed in to

provide a solid connection to the carbody.

Photo [9] shows the trucks installed. I used the new Kadee

No. 564 50-ton Bettendorf Self-Centering Trucks with two-

piece HGC parts for this model. I’m not satisfied with the

appearance of the Accurail Bettendorf truck and have not

found a suitable alternative, but this new Kadee truck side-

frame looks great and operates well, and it is now my new

standard. I ordered the truck sideframes direct from Kadee

without the wheelsets and used Reboxx No.

01-1.030 wheelsets.

Next I constructed the B end of the car. I used many of the

kit-supplied parts, but cut off the retainer pipe and applied

it as a separate piece. I used a Kadee brake wheel and made

my own uncoupling levers from Tichy .010” wire and a few

Detail Associates No. 2206 eye bolts. I also cut the trip pin off

the Kadee coupler and added a Hi-Tech Details No. 6040 air

hose with brass mounting bracket. Since I am modeling an as-

delivered car, I mounted the tack board in the high position. I

finished the A end in the same manner but without the brake

gear, of course!

Next, I moved on to the car sides. Again, this was a simple and

straightforward process. I attached the kit-supplied grab irons,

ladder and car door, and then added the placard and route

car holder to the door. I followed the same procedure for both

sides. I cemented the doors in place.

Last, I constructed the car’s roof. For this model I used Plano

No. 11920 40-foot Gypsum Boxcar Running Board, Diamond

Pattern, which is a photo-etched stainless steel detail part. I

made latitudinal running board supports with Evergreen .010”

9

9. The underframe of the built-up model. I used the Cal

Scale AB valve, reservoir and cylinder but replaced all

the plastic linkage with brass rod. I did not include the

train line or connections from the train line to the valve.

I constructed the underframe on rest of the cars in this

article to the same standard. John Golden photo.

Seaboard B8 & B9 - 7

MRH-Jun 2014