(Cuttingpartsoffof sprues: twohours, 29minutes –Assembly:

threehours, 50minutes).

Phase three assembly – roof

Theparts in this subassembly include the roof, runningboard

(and supports), grabirons, and retainer valves. I built the roof

assemblies, I then glued them to the car bodies.

The roof is thepart of the

car that isusuallymost vis-

ible. Extra caremust be

taken toget the running

boards right.Oneapproach

is toglue the runningboard

to the roof usingguidepins

cast onto the runningboard

that fit inholes in the roof.

Theothermethod calls for

the runningboard tobe

glueddownwithnopins,

directly to thewalk supports

in the center of the roof. I

find thepins candistort the

runningboard, anddon’t

allow it to lieflat on the

roof. I thereforeoften cut

themoffandglue the run-

ningboarddown to the roof

freehand.

Regardlessofwhichmethod

isused, thekeypointsare

toget the runningboards to

Batch-building freight cars - 4

30a

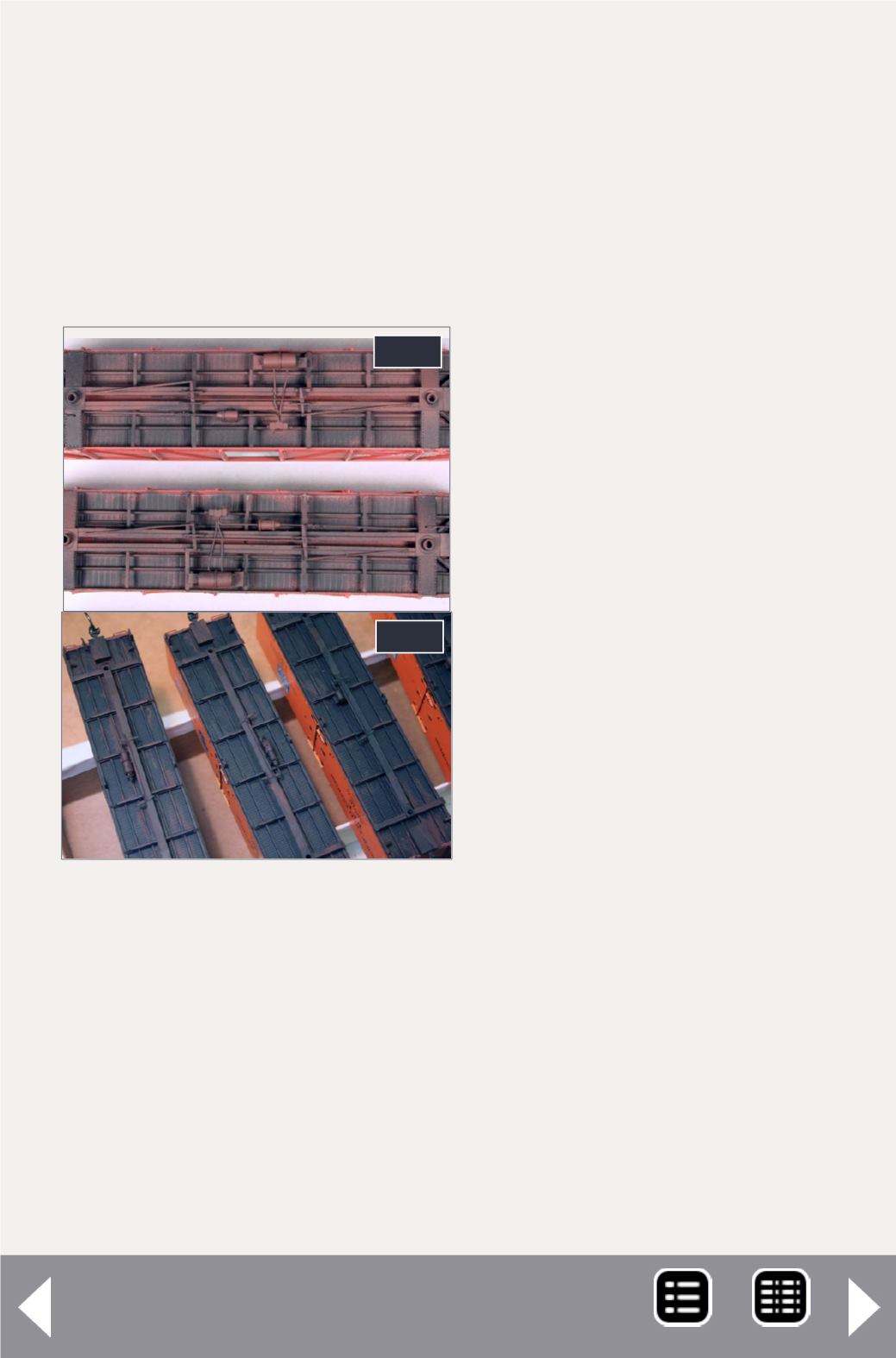

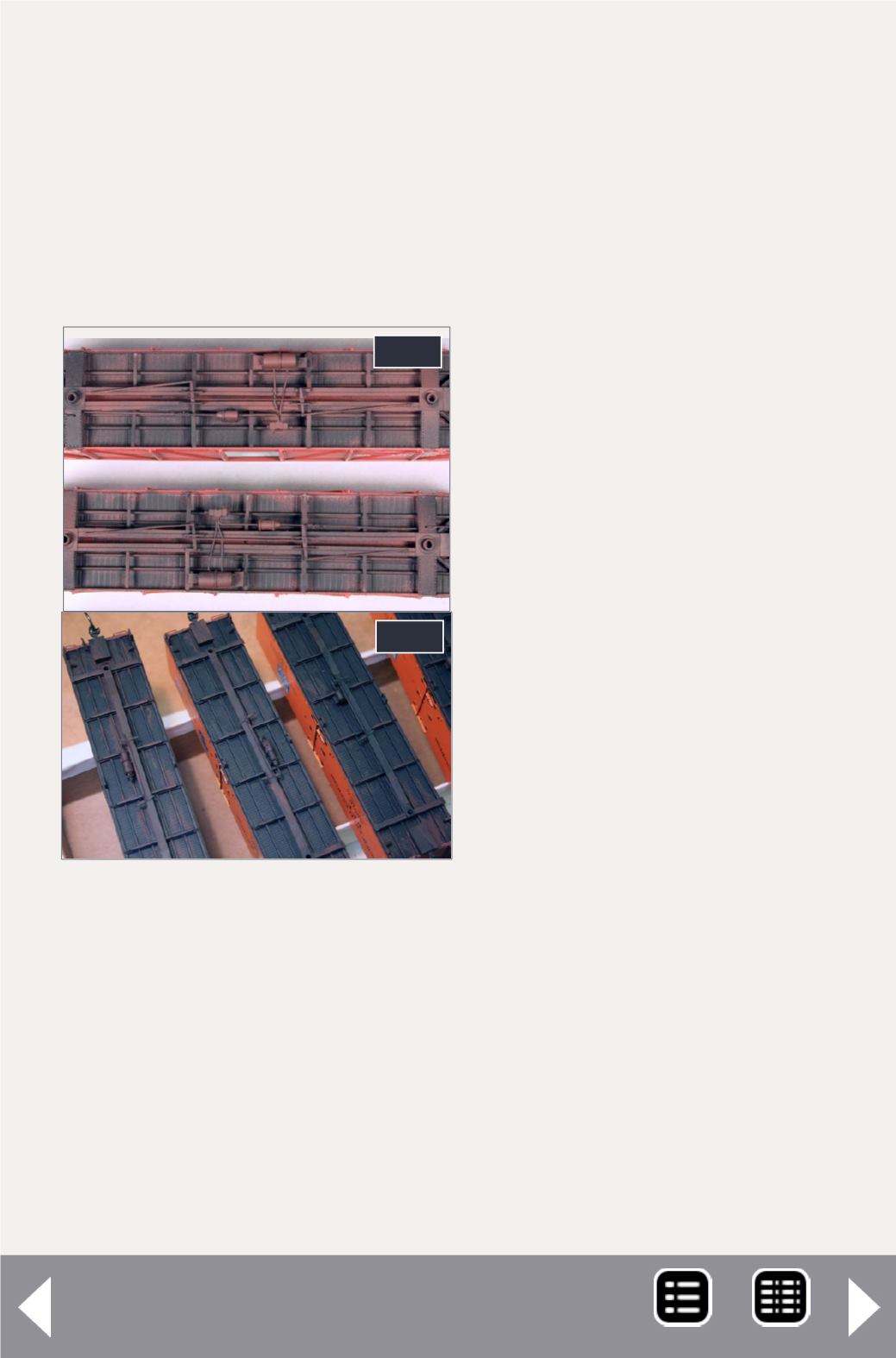

30a-30b: Aboveare

examplesof airbrush

weatheringon the stock

car underbodies. The

airbrushmadequickwork

of theweathering. ThePFE

refrigerator car underbodies

have just thefirst coat of

brush-paintedweathering.

30b

MRH-Apr2014