Shoofly free-moN module - 6

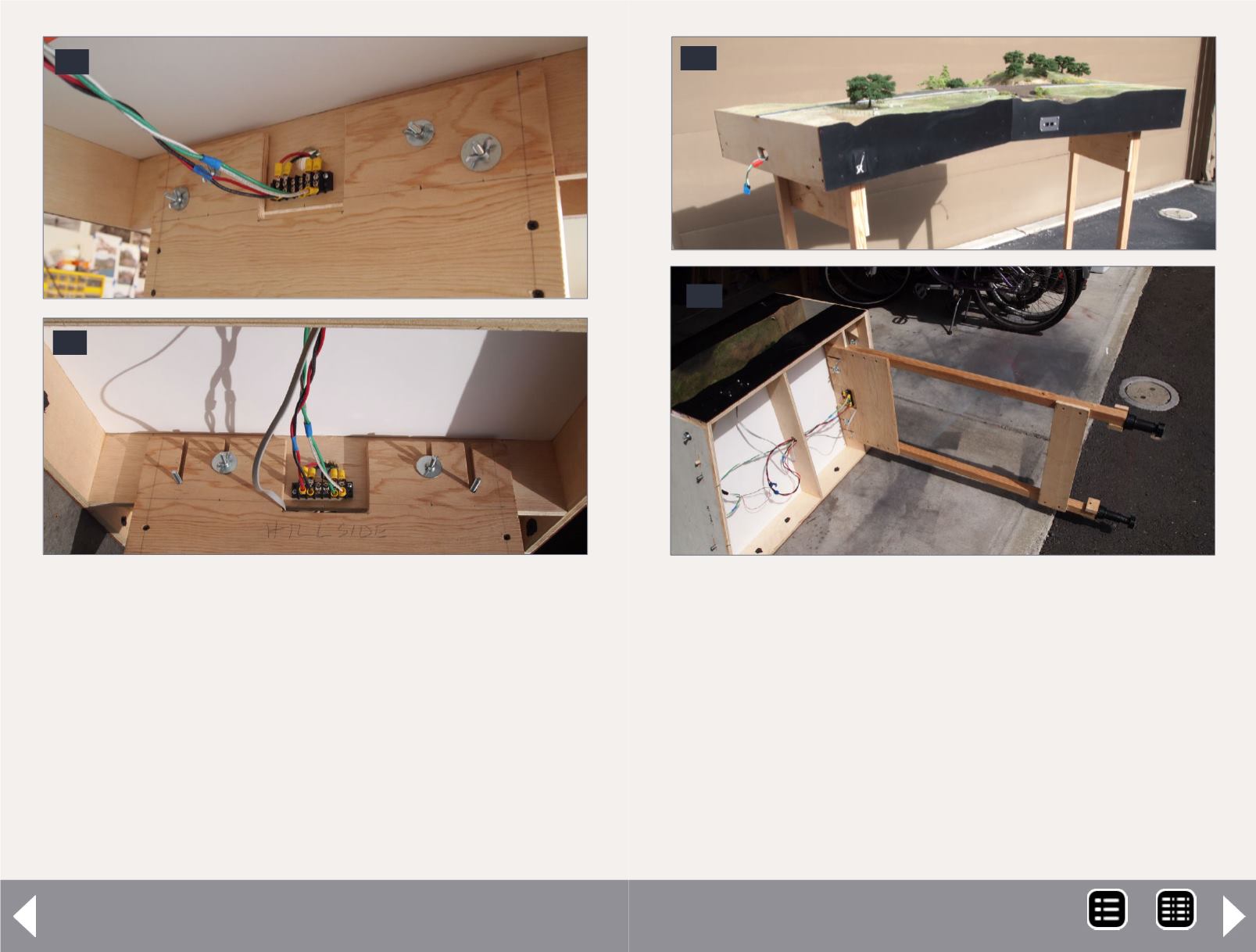

5b

5a

5a-5b: At first I passed ¼” bolts through both cross

supports and leg plate. Cutting notches to allow the

legs to slip onto the bolts saves much time and energy

during setup and take down.

I also did not extend the section end plates up to bookend

the foam, instead allowing the foam from each section to

butt up against each other. Again, it’s held up so far, but The

Voice of Experience says it’s better to have a solid butt joint

with ply, rather than only the softer foam, to extend the life

of the module, especially given the constant set-up, take-

down and transport.

Legs:

The legs are 2”x2”s with a simple frame of ½”-plywood stiff-

ening plates affixed to top and bottom. The top plate extends

4” above the legs with 5/16” slots cut from the top down,

allowing them to slip onto the 1/4” bolts attached to the

cross-supports (5b). Originally I had loose hardware to pass

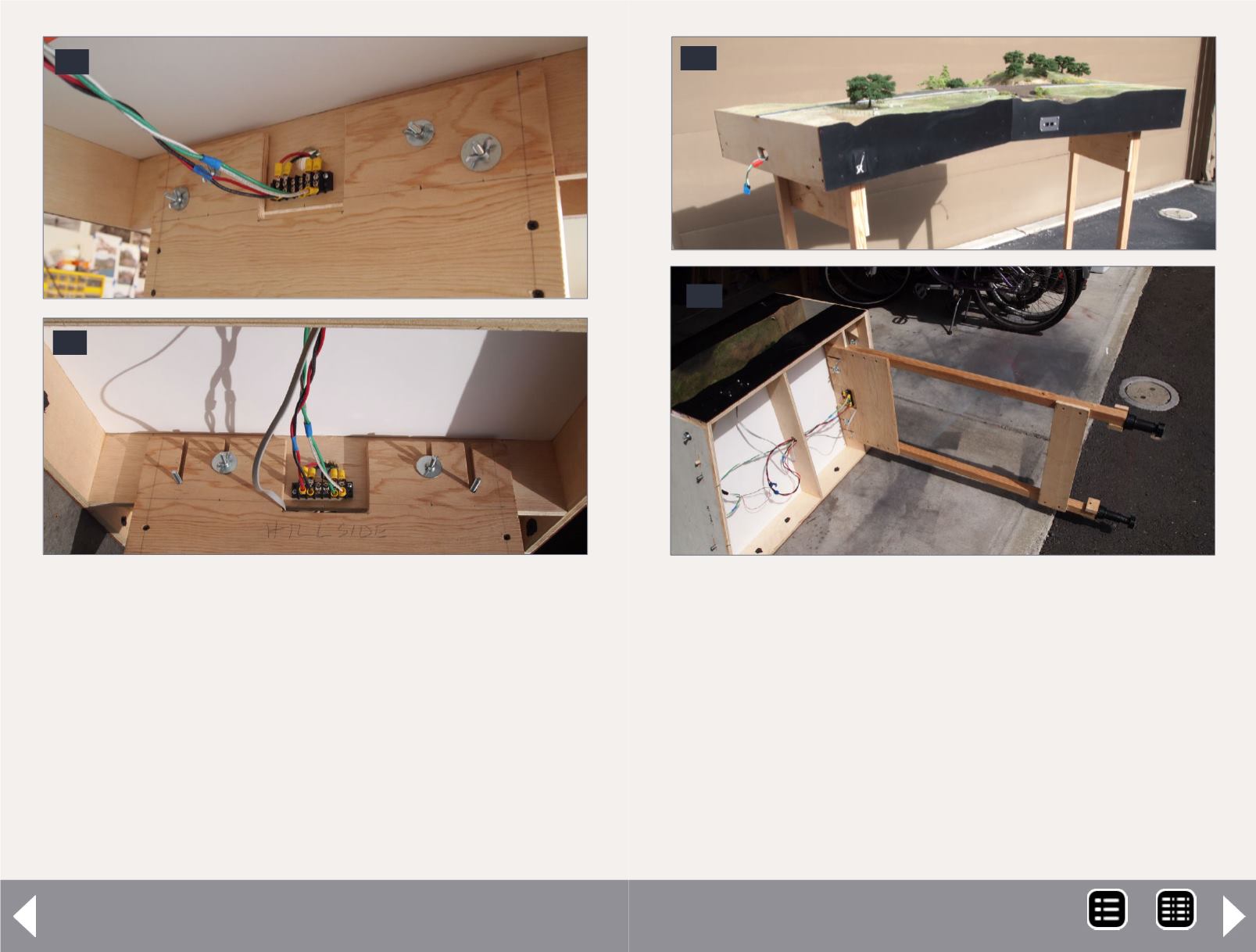

6a

6b

6a-6b: Using ¼” bolts in T-nuts as leg levelers was

cheap but operationally time-consuming and tiring.

Rockler leg levelers are well worth the cost and are

easy and quick to adjust.

MRH-Nov 2013