Shoofly free-moN module - 5

4

3

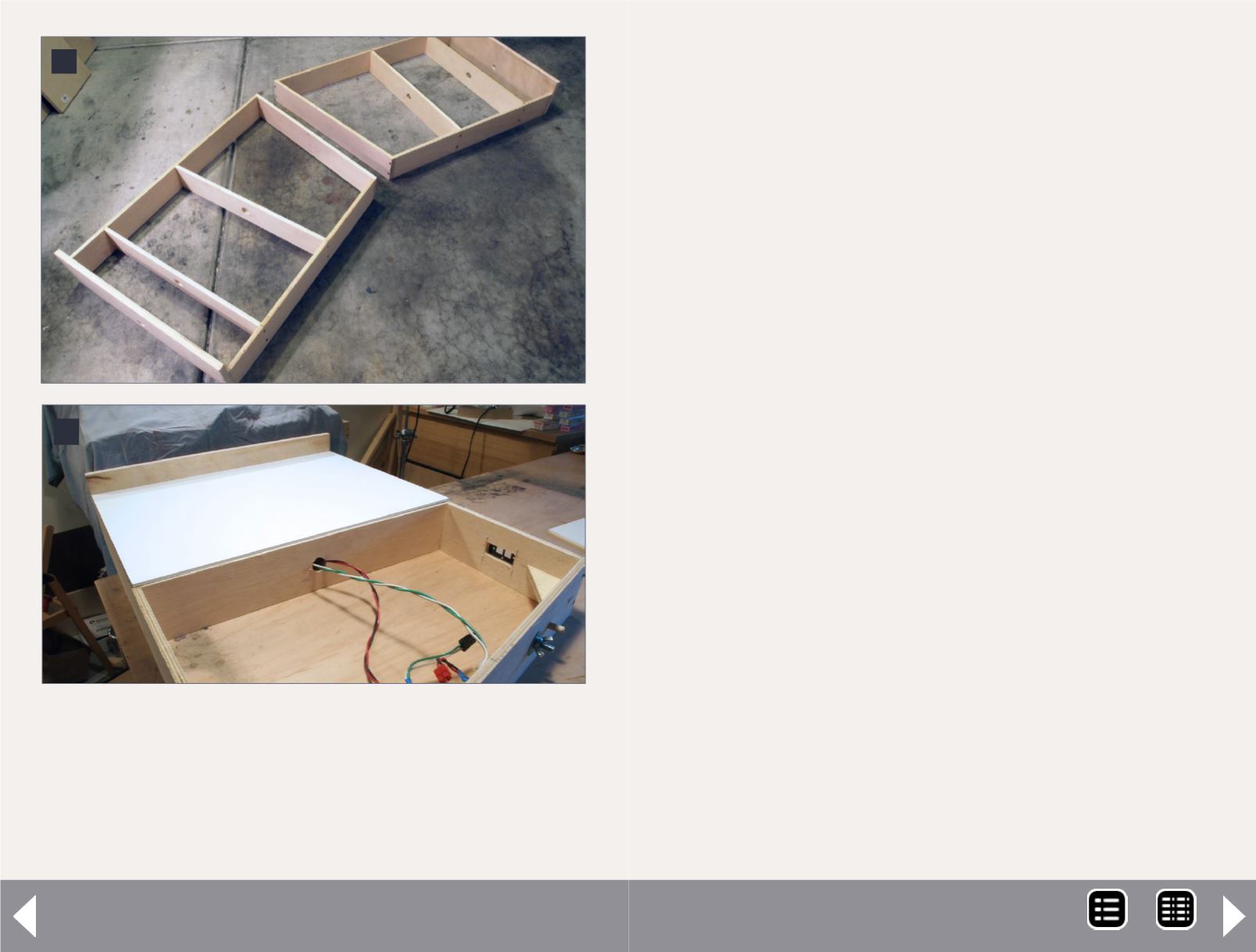

3-4: Free-moN requires ¾” birch ply module end

plates. The rest of the module is made out of ½”

sanded plywood. While I used foam core between the

frame and the 2” pink foam, ¼” lauan plywood would

have been a sturdier choice, despite the slight weight

increase.

The more high-quality detail you have in your scenes, the more

the viewer is sucked in. They don’t even realize the empiri-

cal measurements of the module benchwork while you, as the

module owner, will appreciate the slimmer size when trans-

porting and storing them.

Benchwork Sections:

Just to same-page our terminology: in Free-moN a “module”

is a unit bound by standardized end plates, and may be made

up by two or more “sections” that interface in any way the

modeler wants.

Free-moN standards call for ¾” birch plywood end plates. The

high-quality ply ensures the non-warping surface necessary

for clamping smooth butt-joints together but unless you have

the arm strength of (Charles) Atlas, you don’t want to build

the entire module out of the heavy wood. So I glued-and-

screwed ½” sanded ply to construct the rest of the bench-

work, with angled gussets to reinforce the crossbeams and

sectional end pieces (3) An adjustable miter chop saw made

the angles a snap.

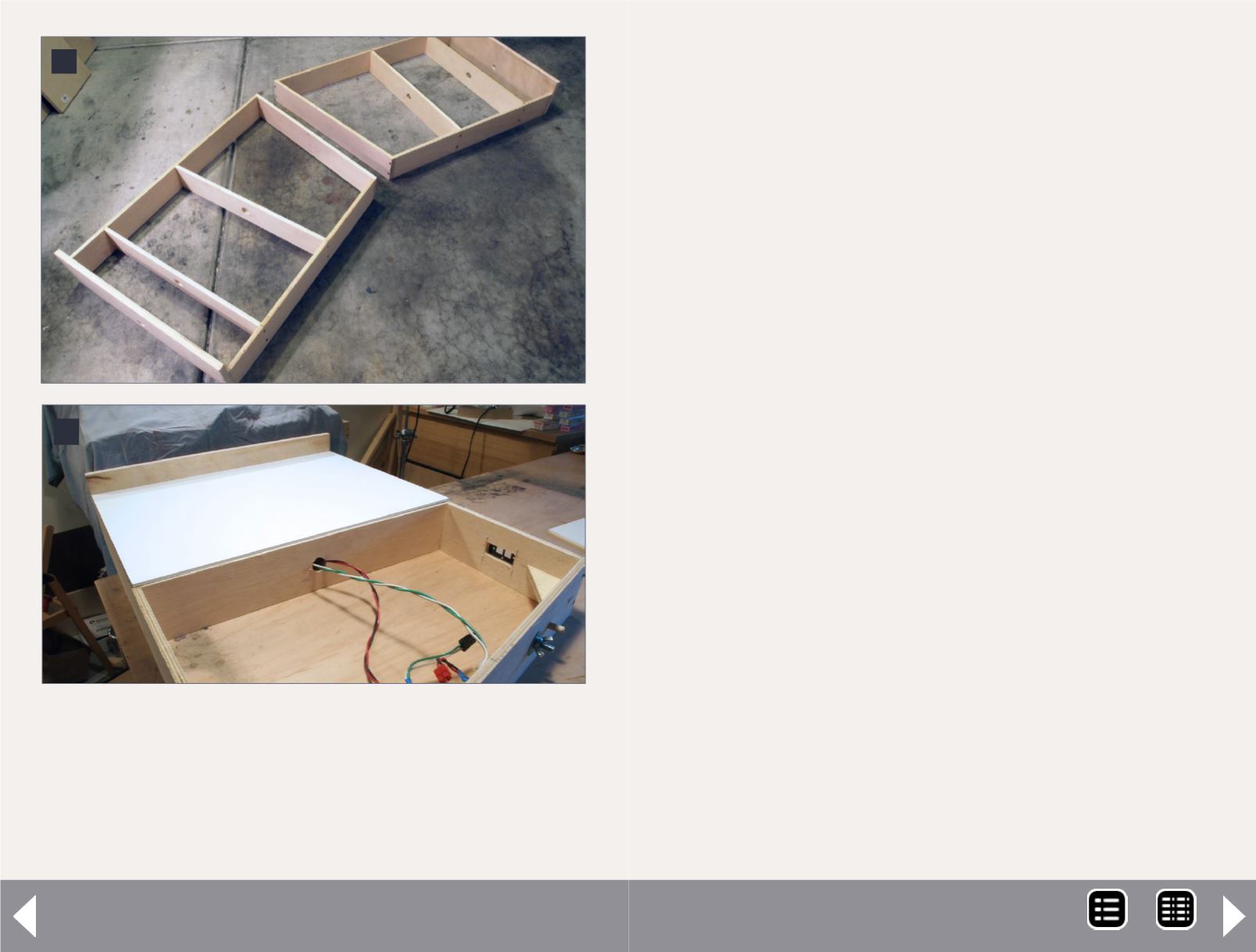

Mindful of using more wood with its increased weight, I

glued a section of foam core under the 2” pink foam (4) to

cap the ply sections. While the sectional benchwork has held

up well over the past two years, the Voice of Experience

notes that a 1/8” or 1/4" lauan baseboard would have

bonded better to the framework, provided a sturdier base for

the turnout control, and probably prolonged the structural

life of the module over time.

“The more high-quality detail you have in your

scenes, the more the viewer is sucked in. ”

MRH-Nov 2013