The Tool Shed - 4

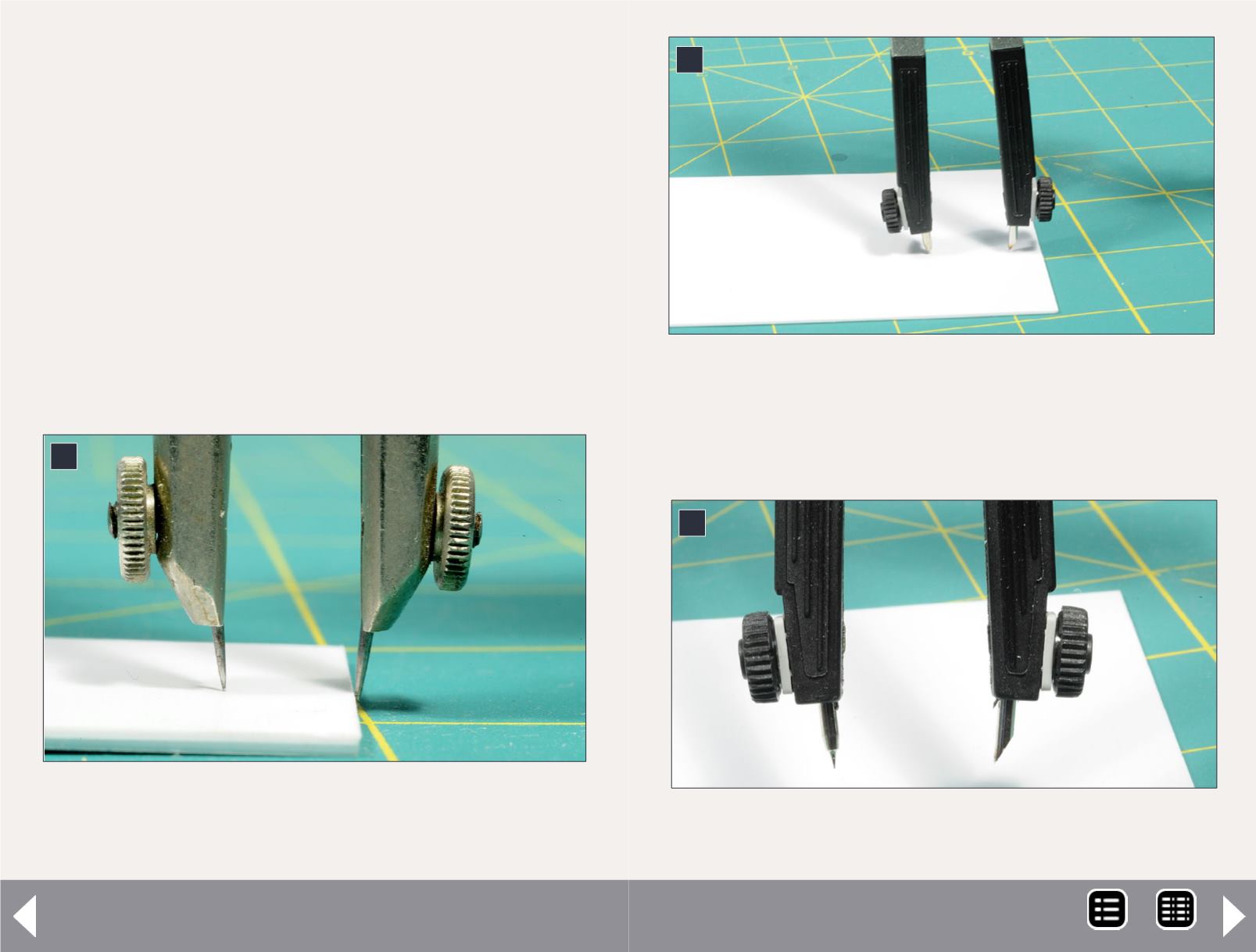

5: When scribing thicker materials such as this .040" sheet of

styrene, extend one leg of the dividers as shown in this photo.

That makes it easier to follow the edge of the sheet of styrene.

5

to be cut to a larger sheet of thick (such as .040″) styrene;

as the center leg of the compass pushes through the thin

material it will stay in place via the underlying material.

Large round discs are needed when scratchbuilding water and

fuel tanks. I typically use .040″ styrene for the tops and bot-

toms of such tanks and the regular needle doesn’t work that

well (6) since it tends to cut a V-shaped slot. In those cases I

will grind the needle to a chisel shape as shown in Photo 7.

Note that most compass needles are double-ended so that

you can grind one end and still have a pointed needle end for

transferring dimensions. The needle is positioned in the com-

pass with the cutting edge closest to the center of the circle.

Again, make a number of passes and then either snap the

styrene piece out, or finish up with a hobby knife after

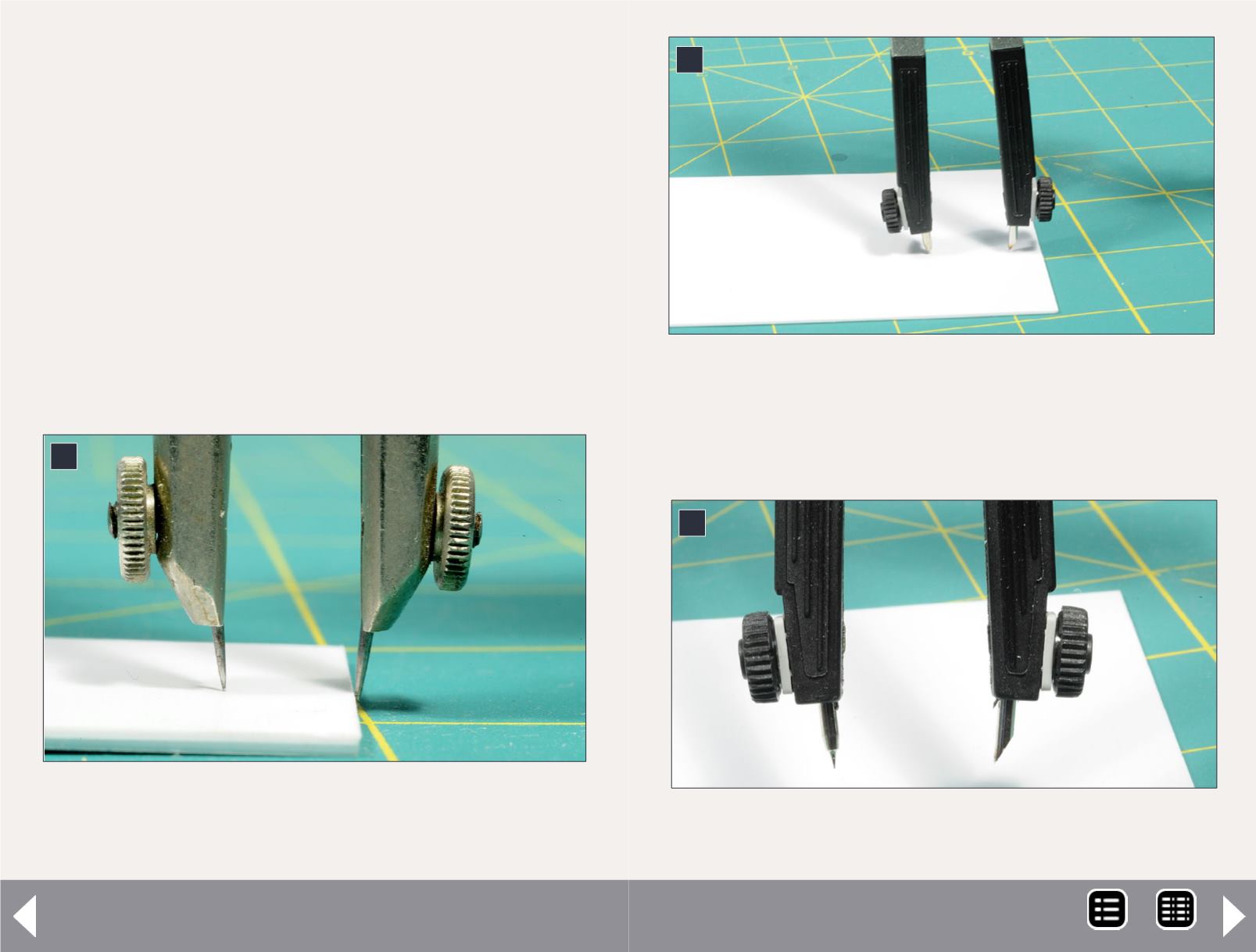

6: This photo illustrates using the larger compass to cut out

a round styrene disc. Repeated passes are needed and it is

usually easier to move the styrene than to rotate the compass

around a complete circle. The needle on the cutting leg has

been ground to a cutting edge.

6

7: This chisel point was ground to result in a cutting edge on

one of the needle points on the compass.

7

MRH-Oct 2013