motor, the orange wire will go to the M+ pad and the gray wire

to the M-pad.

If you are at all unsure as to whether you got the motor polar-

ity right, leave the wires long and just tack solder them into the

motor pads. After you test the loco, you can cut them to length

and dress them.

10.3 Wire speaker

Make sure the speaker wires are dressed such that they won’t

interfere with the swing of the front truck. I like to hook them

around the boss that previously held the copper contact strip

for the right side of the trucks. If the wires are a bit stubborn, I

will even put a dab of caulk between the wires and the enclo-

sure and clamp them in place to keep them out of the way of

the wheels.

Solder the speaker wires to the speaker terminals on the

decoder. The polarity makes no difference, since this is a single

26

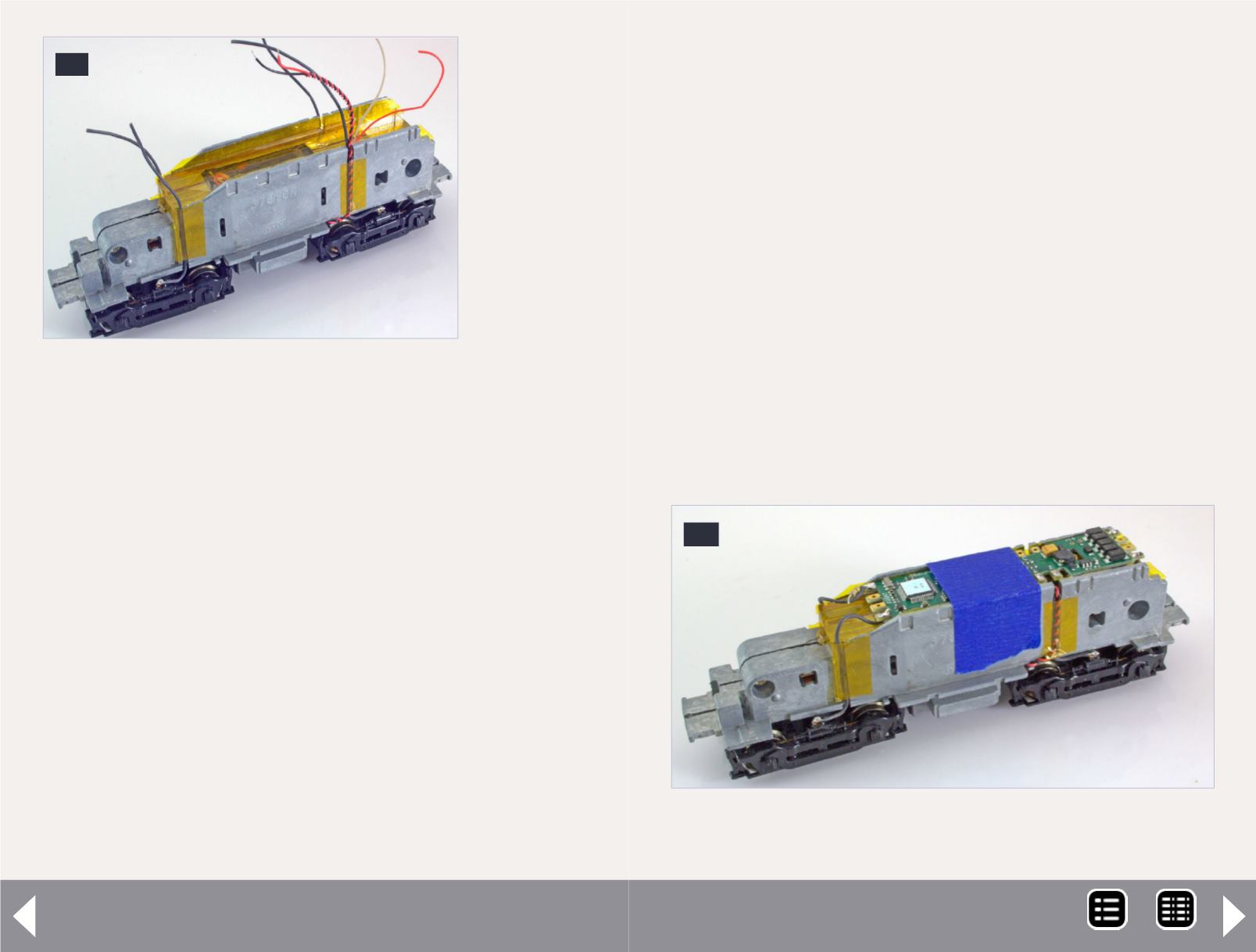

26: TSU-GN1000 decoder held temporarily in place with

blue tape.

10.0 Install and wire decoder

Now, we get down to the fun part. You can see the locomotive

return to running condition. Figure 26 shows the locomotive at

the end of the work here in section 10.

10.1 Set decoder in position and secure

In the end, the decoder is not held in place by any mechanical

method. The sides of the frame will keep it in line (that’s why we

put Kapton tape on them). The wires will hold it front to back.

This installation is designed for the SoundTraxx TSU-GN1000

decoder (part number 678-828050 with the EMD 567 sound

file). The decoder needs to be installed with the FRONT letter-

ing toward the back of the loco and the power supply capaci-

tors in the well behind the headlight. Hold it temporarily in

place with a bit of blue tape, as shown in figure 26.

10.2 Wire motor

Cut the orange and gray wires to length and solder them to

the motor pads. If you observed polarity when removing the

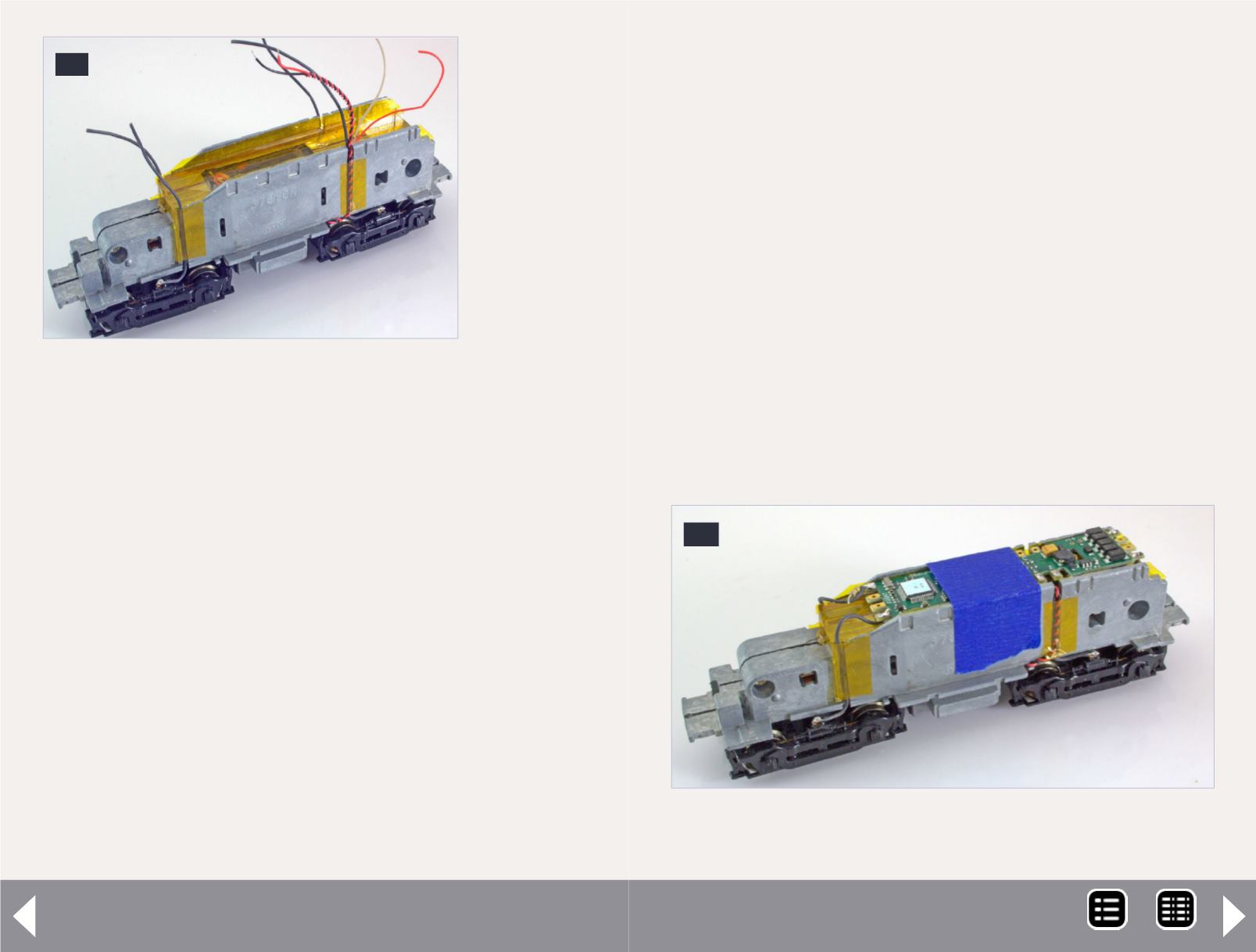

25

25: Top

view of

the trucks

wired,

after

Kapton

tape has

been

applied to

hold the

wires in

place.

DCC Impulses column - 15

MRH-Jan 2013