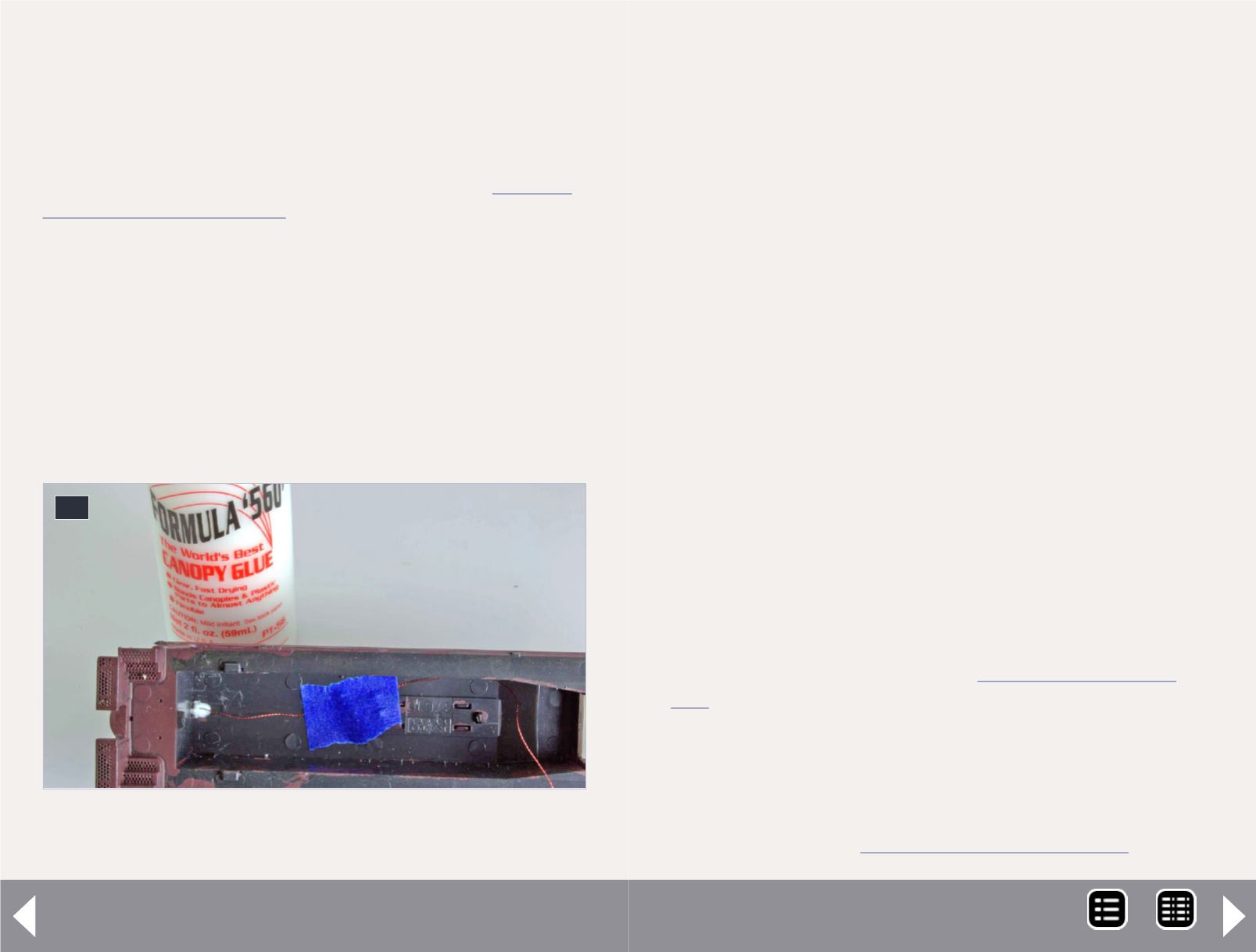

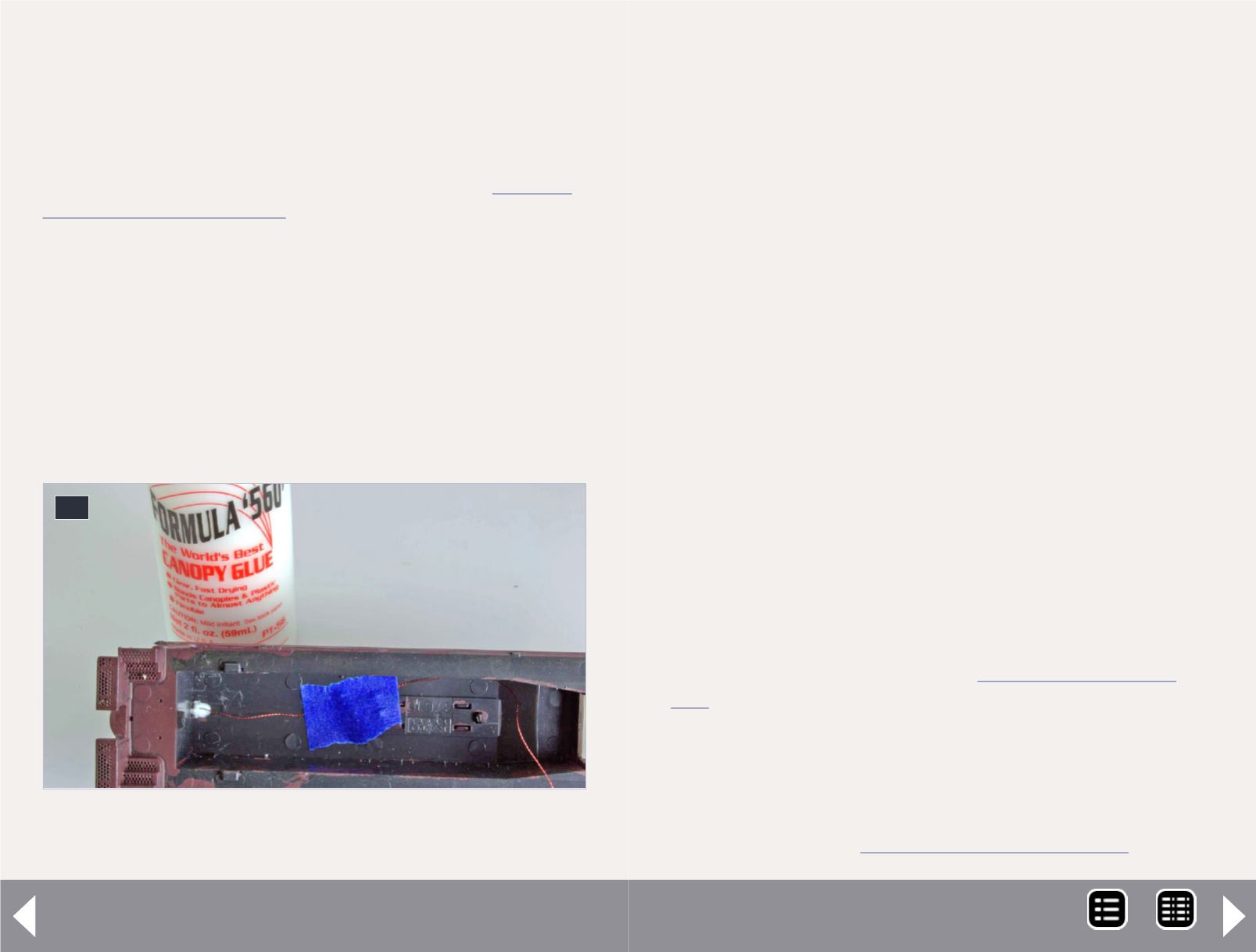

A piece of blue painters’ tape holds the LED in place by its

wires in the top of the shell. Slide the LED into place and

observe that it is positioned to shine out through the lens.

Then put a drop of Canopy Glue to hold it in place, as in figure

13. Set it aside to dry for at least a few hours before working

on the shell again.

3.3 Fix Cab Floor

Several of the locos I did in this batch had had DCC decoders

installed previously. The cab detail floor had been cut away to

provide a place for a very small decoder to reside. I fixed the

cab floor by cutting a piece of 0.02-inch thick plastic (black,

in this case) to fit over the hole. I glued it in place and spray

painted it with Krylon gray primer. You will only need to do this

if your loco has had the integrity of the cab details damaged in

a prior installation. Set it aside to let the paint dry. We won’t

use it until the final assembly. See figure 14.

4.0 Machine frame

The key to this installation is to get enough room in the frame

for the decoder, speaker and wires. This requires a bit of fancy

milling. George at TVW Miniatures

designed this version and offers frame machining ser-

vices. Even though I have a mill, I had him do the machining.

Kato no longer has stock of the frames, so if you mess up your

frame, you may never get your loco back running.

If you are going to machine them yourself, there are dimen-

sions on my web site

.

DCC Impulses column - 8

them with a 6-inch long set of wires connected, so there is no

fancy soldering needed to get wires on the LED.

I like to connect the LED to a buzzer (9 volt battery and buzzer

combination) that limits the current through the LED and

allows me to view the light, as I’m installing the LED. For infor-

mation on the buzzer, see my January 2012 column

.

One of the best-kept secrets in model railroading is Formula

560 Canopy Glue. This glue is well known to the RC plane folks.

They use it hold the canopy onto their planes, hence the name.

It bonds almost anything and dries clear. I’ve even made win-

dows out of it. It also dries quickly, so I use it instead of white

glue for wood structures, as you can slap things together

quickly and they will hold their shape. It will take 24 or more

hours for the glue to be fully cured, hard and clear.

13

13: Front SMD LED held in place with blue tape while

Canopy Glue dries.

MRH-Jan 2013