29

29: Finish the fuel tank with speaker grille cloth and mod-

ified plastic parts.

14.3 Final lubrication

Remember that we only put light (10) weight Nano-Oil on

the gears? Well, it is time to provide longer-term lubrication

with heavier weight Nano-Oil. With the loco still in the cradle,

put one drop of the 85-weight Nano-Oil on each of the four

exposed gears on the bottom of the loco. When you run the

loco, this will get distributed throughout the entire gear train,

all the way up to the worm gear.

Dirt and corrosion are enemies of electrical contact, making

for irregular sound and performance. Daylight Sales provides

the electrical equivalent of Nano-Oil, called Never Stall. It lubri-

cates and cleans electrical contacts and inhibits corrosion. Put

a drop of Never Stall on each wheel bearing where it contacts

the copper pickup plate.

14.4 Reinstall couplers

Now you will understand why I wanted to take the couplers out

in one assembly for each end of the loco. You can just snake

items from your roadbed. If they bounce around on the

speaker cone, the sound gets really bad.

Now it is time for the black panty hose. I’m sure that those

of you who looked at the parts list ahead of time have been

scratching your head on that one.

Remember that the speaker enclosure was a bit longer than

the boss molded into the frame to hold the fuel tank? Okay,

here’s how we deal with that one.

Cut the sides off the plastic fuel tank detail part. Check the

sides to fit against the metal bosses on the frames. Make sure

you have the correct detail part on the correct side of the loco.

They are not the same. The left hand side has a piece that

extends fairly far forward. The right side piece doesn’t extend

as far back.

Cut a piece of black panty hose to cover the speaker from front

to rear and to extend side-to-side about half way down the air

tanks. Carefully (I use a toothpick) apply a bit of caulk all the

way around the speaker. Don’t get any on the cone, as it will

dampen the sound. Slightly stretch the panty hose material

and press it down onto the bead of caulk you created. Apply

a fairly large bead of caulk on the air tank area and press the

sides in place and down against the frame. Use a one-handed

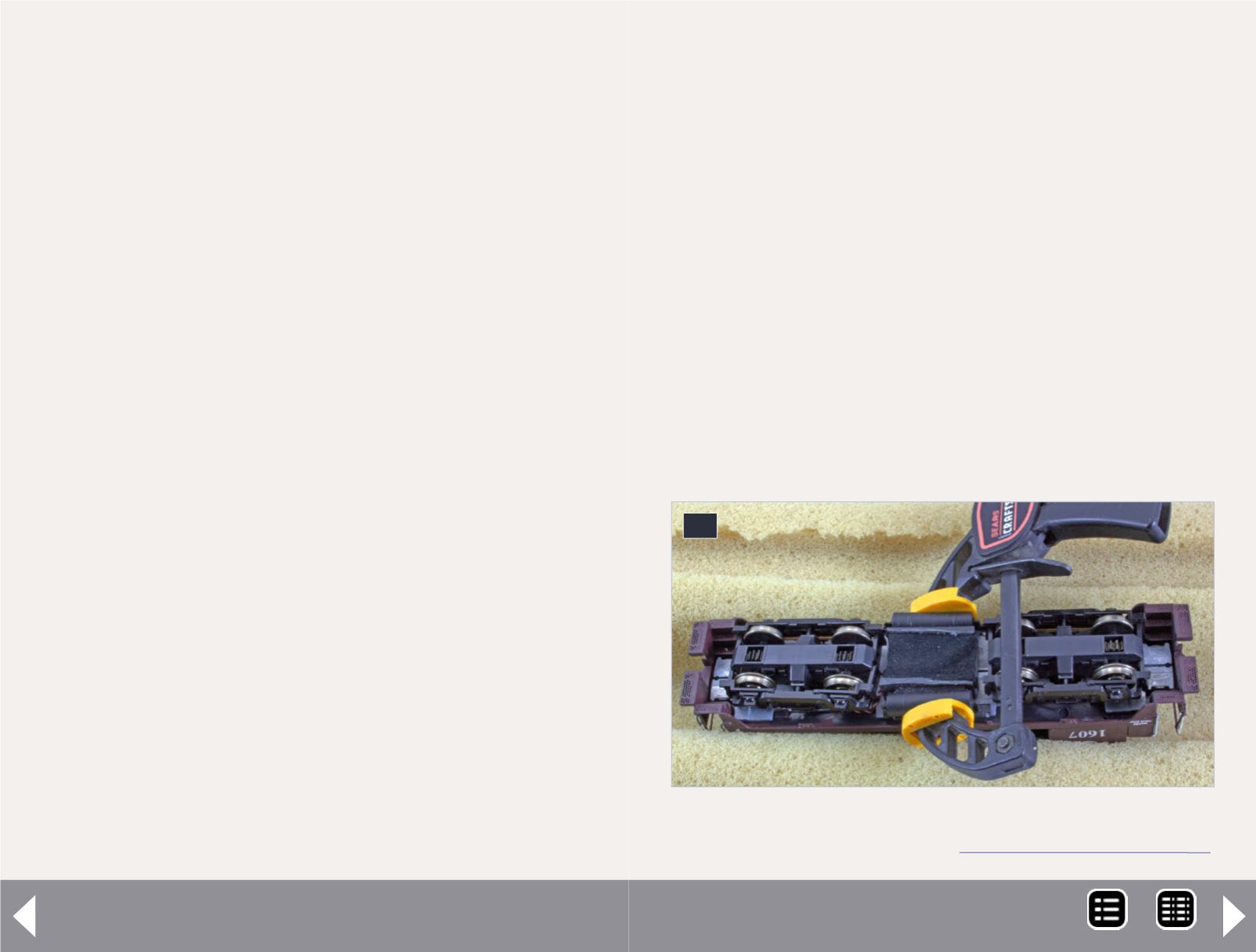

bar clamp (29) to hold them in place for a few hours until the

caulk sets up – I recommend overnight.

Now you have some grille cloth on top of your speaker to help

control the debris pickup. It won’t prevent the pick up, but will

help keep the debris away from the speaker cone. I recom-

mend checking for accumulation from time to time.

While the caulk is setting up, we can do some of the final work

with the loco in the foam cradle. Just be careful not to bump

the clamp.

DCC Impulses column - 19

MRH-Jan 2013