2.2 Disassemble the drive train

The next step is to disassemble the “guts” of the locomotive.

Here is where you will really appreciate the details on my video

(see photo 11).

Corral the parts in a box or something that can be covered,

especially if you are sending the frame off to be milled and

won’t be reassembling the loco in a few hours.

Remove the copper pick-up strips and the headlight board.

They will not be used in the final loco assembly.

Remove the screws and nuts.

Split the frame slightly and mark the motor as explained in

section 2.1

Set the trucks aside. Some folks like to mark front and rear

trucks for reassembly in the same location. I haven’t

seen much variation in these locos; so I don’t worry about it,

at least with this model.

Remove and store the pieces of the drive train – don’t over

look or lose the adapter bushings inside the flywheels.

Remove the insulating bushings from the frame halves.

Remove the (copper) bearing retainer clips from the right

frame half.

You should now have two pieces of gray metal (the frame

halves) with nothing on them. Now is a good time to use some

denatured alcohol and a stiff brush and some Q-tip(s) to clean

the frame halves of built-up lubricants and dirt.

The frame halves are ready to be machined.

DCC Impulses column - 6

2.1 Marking the motor

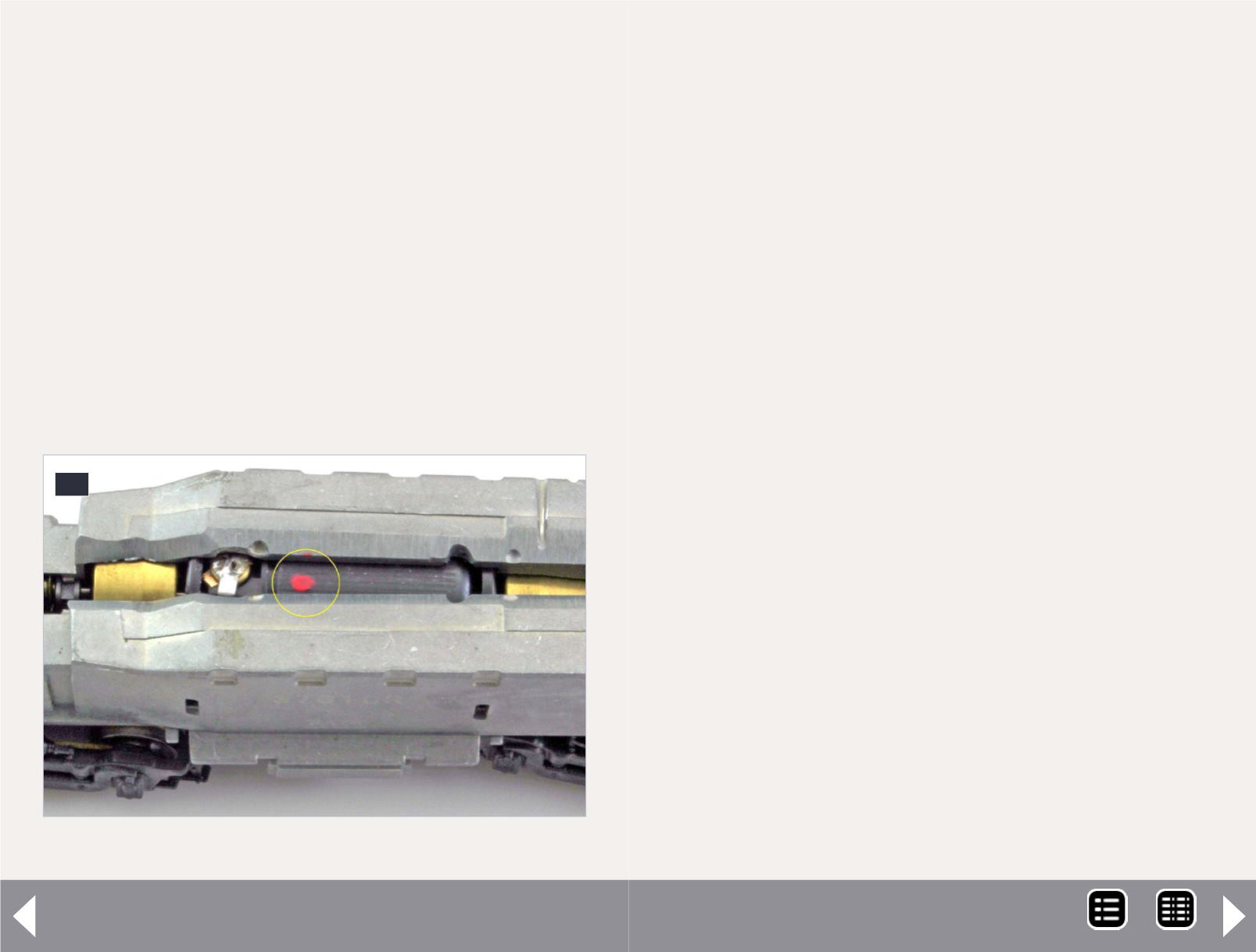

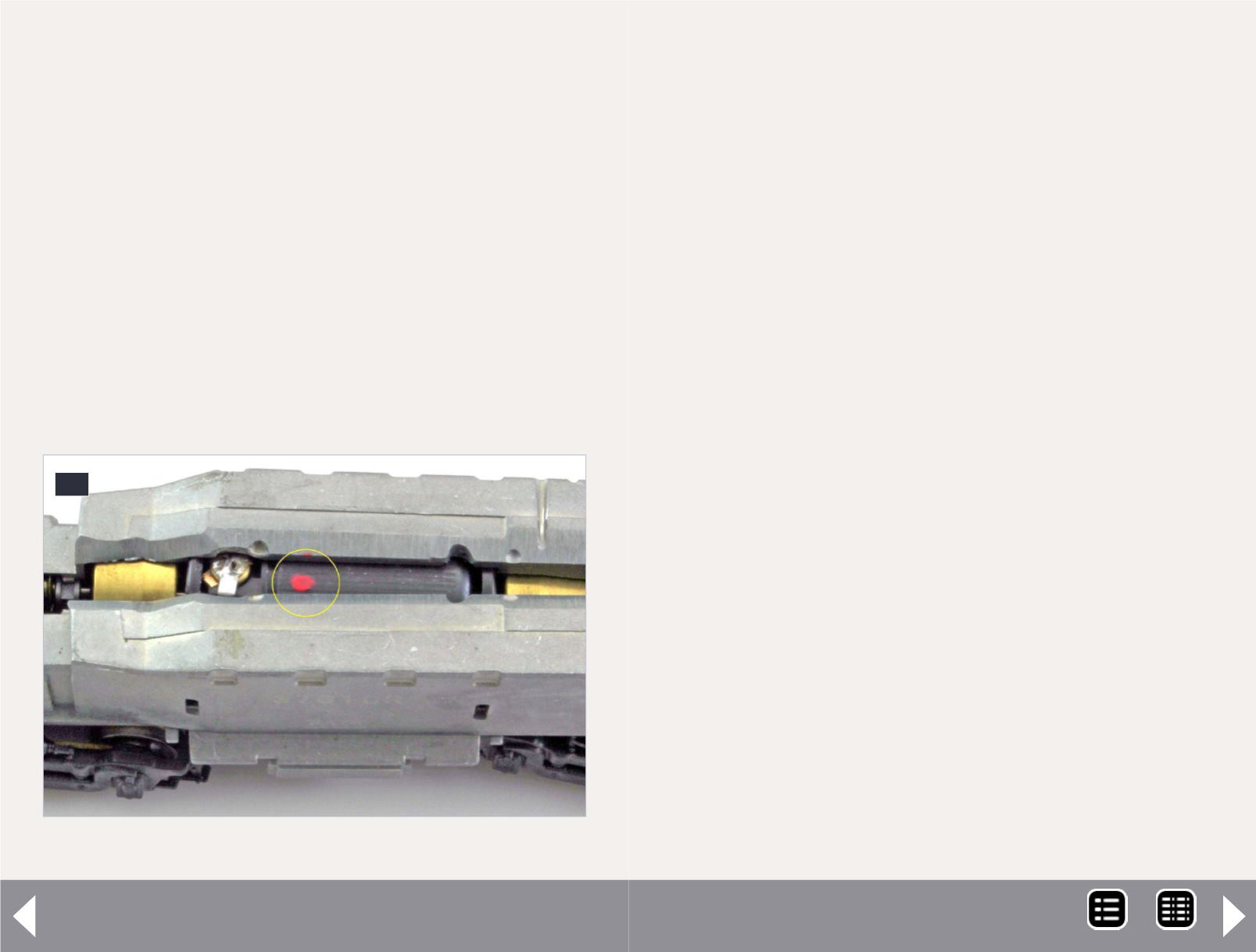

Before you split the frame completely apart, note that the top

motor brush connects to the right-hand frame half (10). Mark

the motor near this brush holder in some way that you will be

able to use later during the reassembly process. I use a red or

orange paint marker. Since this dot is on top of the motor, it

tells me which way is up when I reassemble the loco.

The motor, shown in figure 10, has had DCC connected to it, so

the tab had been removed. I soldered a tab in place so that you

can see the idea. The tab comes toward you in figure 10 and is

covered with solder. A factory fresh loco won’t have the solder,

just the copper parts.

10

10: Marking the motor brush connected to the right rail.

MRH-Jan 2013