Shell preparation

The shell of the RS-11 needs holes to allow sound egress; a

bit of thinning inside at the front to create additional space

for the decoder, and some trimming of the plastic number

board/headlight inserts to create additional linear space for

the decoder and speaker. First, I trim back the rear part of the

number board inserts.

Next, I thin out the front of the shell just a bit using a 1/4” 250-

grit sanding drum on a Dremel. The stock shell has about 10.3

mm of space inside, and the LokSound decoder is 10.6 mm

wide; so I thin the shell by about .3 mm. I use digital calipers to

measure, but you can use the decoder to test the fit.

9

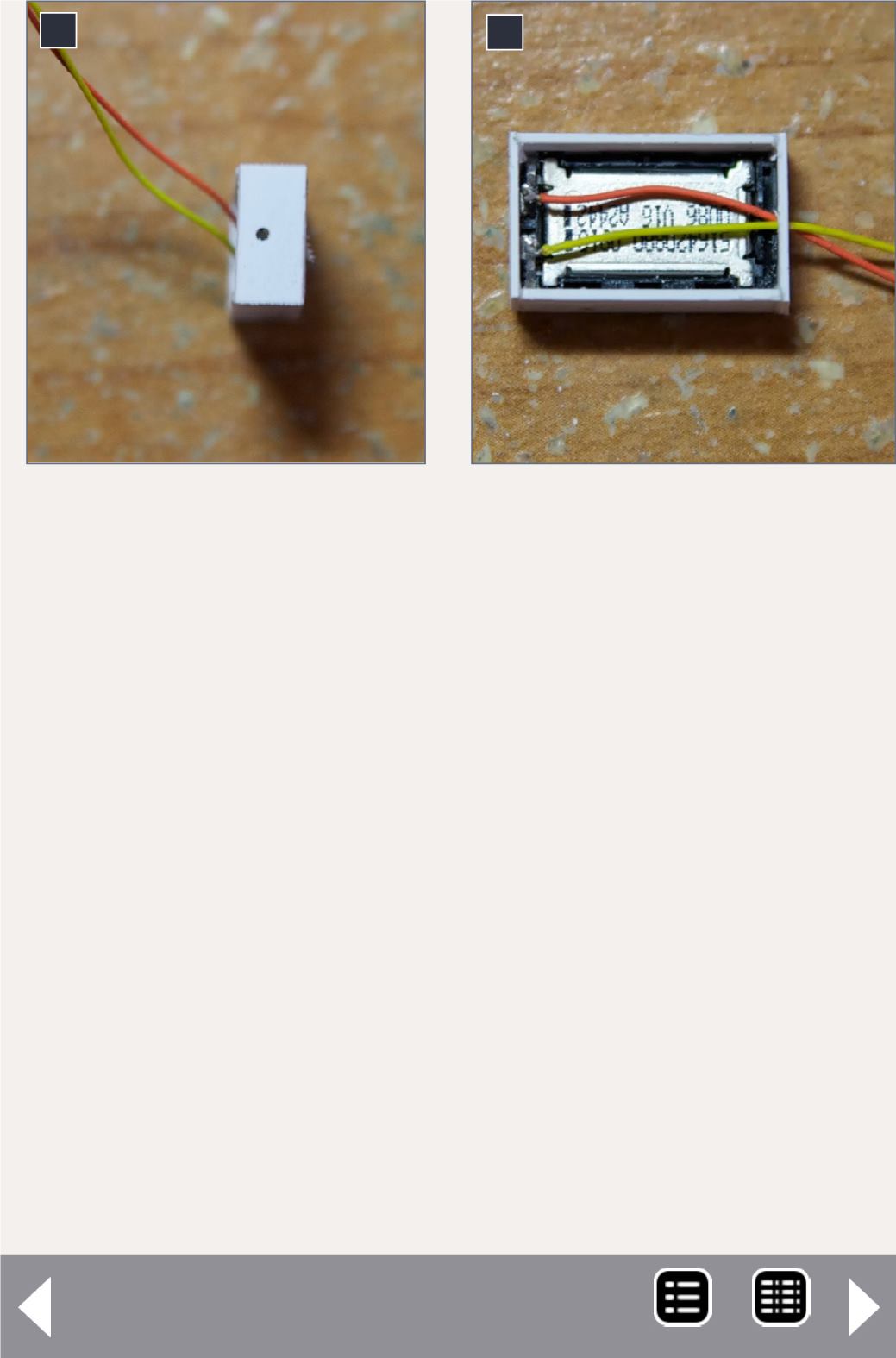

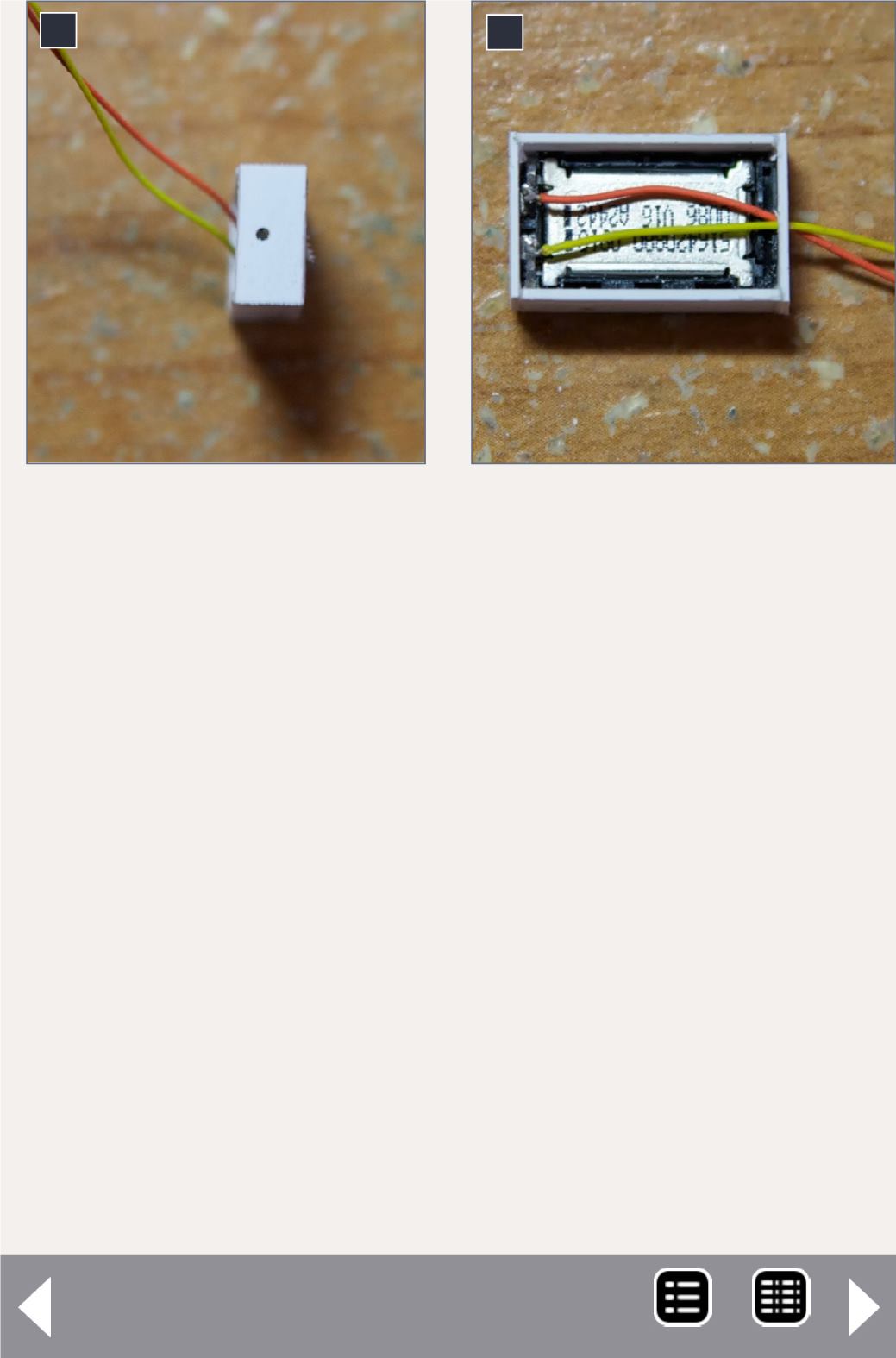

9. The sides of the

speaker box are

finished. The wires feed

through the hole.

8

8. A small hole is drilled

in the last side, to feed

the wires through.