10 mm of interior space in the shell, I chose .020” styrene for

my enclosure. It adds about ½ mm of width to each side, or 1

mm overall.

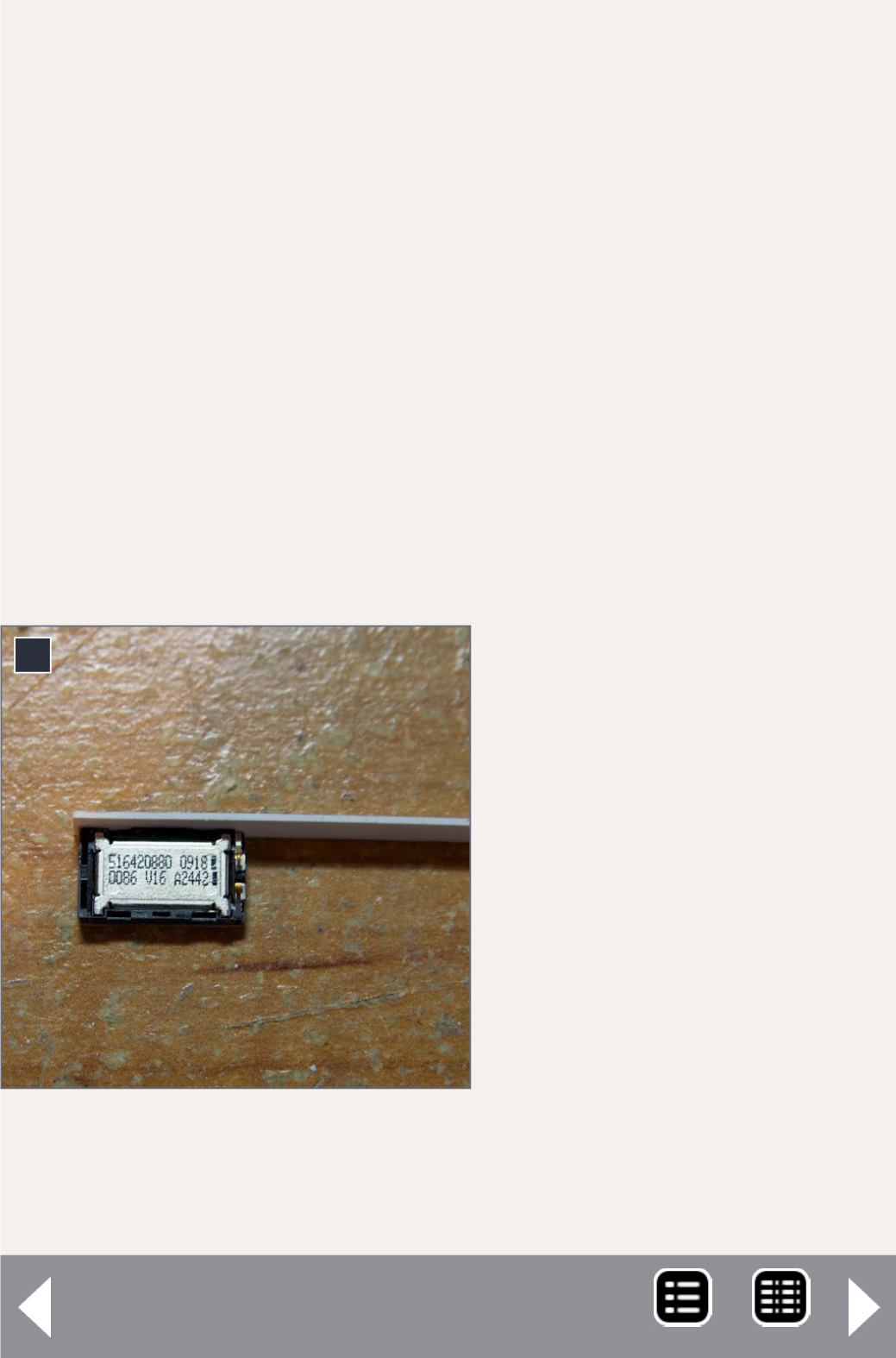

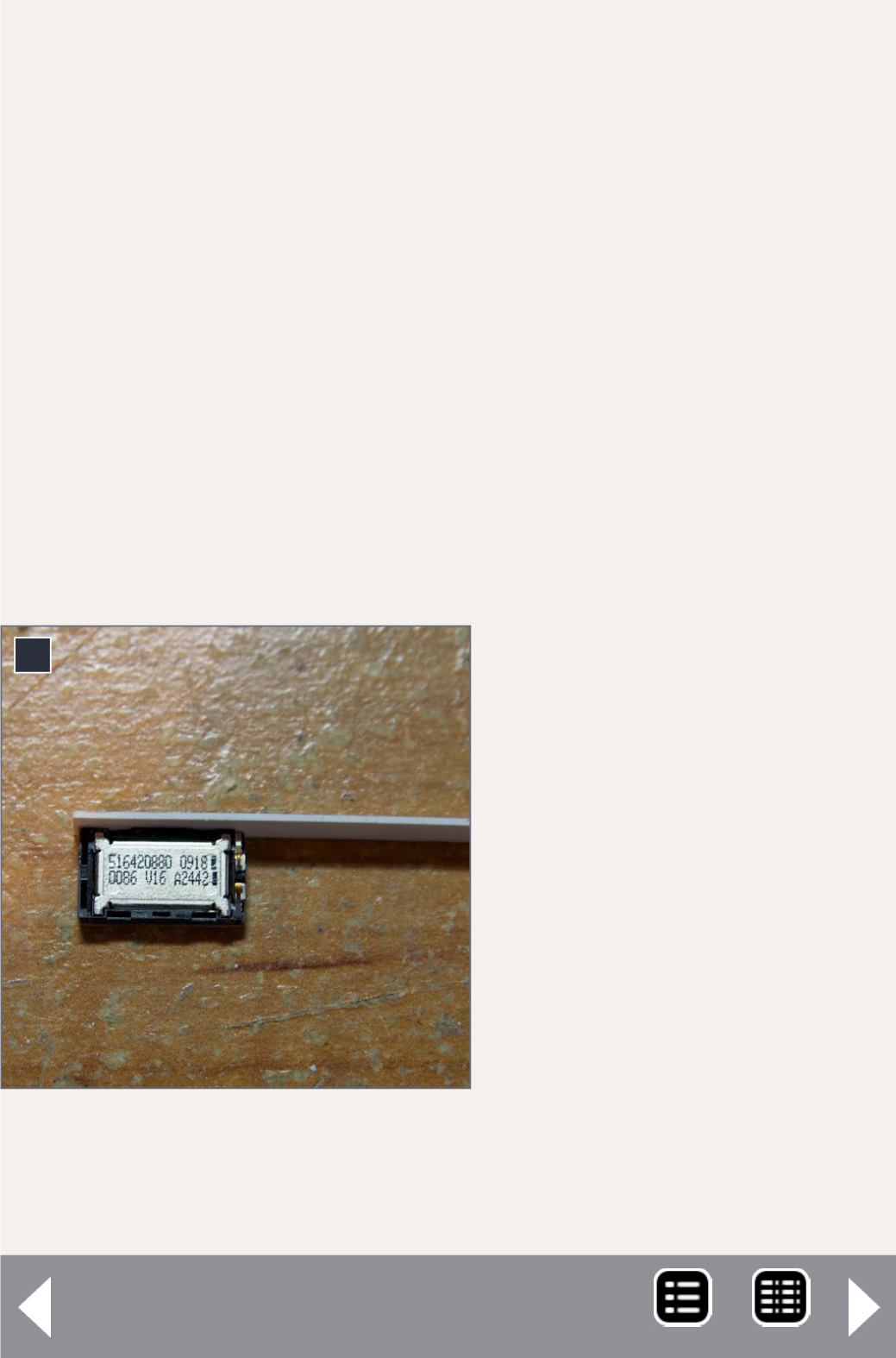

The first step for my installation involved soldering wires to the

speaker and building the speaker enclosure. The speaker wires

were 30-gauge wires cut off from prior decoder installs. I have

a box of these wire pieces that I save for just this kind of use,

but you can order 30-gauge flexible wire from several sources.

My measurements indicated that I had about 6 mm between

the frame and the top of the shell, so I cut a strip of .020’ sty-

rene 5.5 mm wide. The bottom of the enclosure would add 1/2

mm, bringing the total to 6 mm. To make the enclosure, I con-

structed a box around the speaker, using CA cement to glue the

styrene sides to the side of the speaker, and regular liquid plas-

tic cement to attach the bottom of the enclosure.

The first step in the pro-

cess is to “rough up” the

sides of the speaker with

200 -grit sandpaper to

provide better adhesion

for the CA cement. I also

lightly sand the styrene

strip.

Now it’s time to build the

box. I put a thin bead of

gel CA across one of the

long sides of the speaker,

towards the top edge, and

then press the styrene

strip onto the edge. I usu-

ally put the speaker face-

down on my work table,

then press the strip along

4

4. Glue styrene to the long

side of the speaker, and trim

to the correct length.

N scale sound - 3

MRH-Dec 2014