flywheel. Too much cutting here and you’ll cut through the

frame (ask me how I know this).

After you are done, insulate the area of the frame where the

motor contact strips come up to contact the circuit board. I

use Kapton tape for this. We won’t be using the circuit board,

so you want to make sure these strips can’t accidentally con-

tact the frame and cause a short.

Photos [20-22] show the cut frame. The speaker will go on

the rear of the frame, and the frame is reassembled with the

motor inside and the Kapton tape insulating the areas around

the motor contact strips.

The last prep step is to cut a small piece of old circuit board to

solder the decoder power pickup wires.

That’s it for the prep steps. Now it is time to install the decoder,

headlight LED, and speaker.

Final assembly and wiring

Cut the LokSound wires to the right length. The exact length

will depend a bit on the exact placement of the decoder on the

frame, but the orange wire is about 20 mm; the gray about 22

mm; the red and black about 32 mm. Then I strip the ends of

the wires and tin them with solder.

Before installing the decoder, I install the surface-mount LED

for the front headlight. I use a sunny white SMT LED from

Richmond Controls that comes with 6” fine magnet wire

attached. You want just enough wire to loop at the end of the

“channel” in the top part of the frame and hook to the white

and blue wires.

18

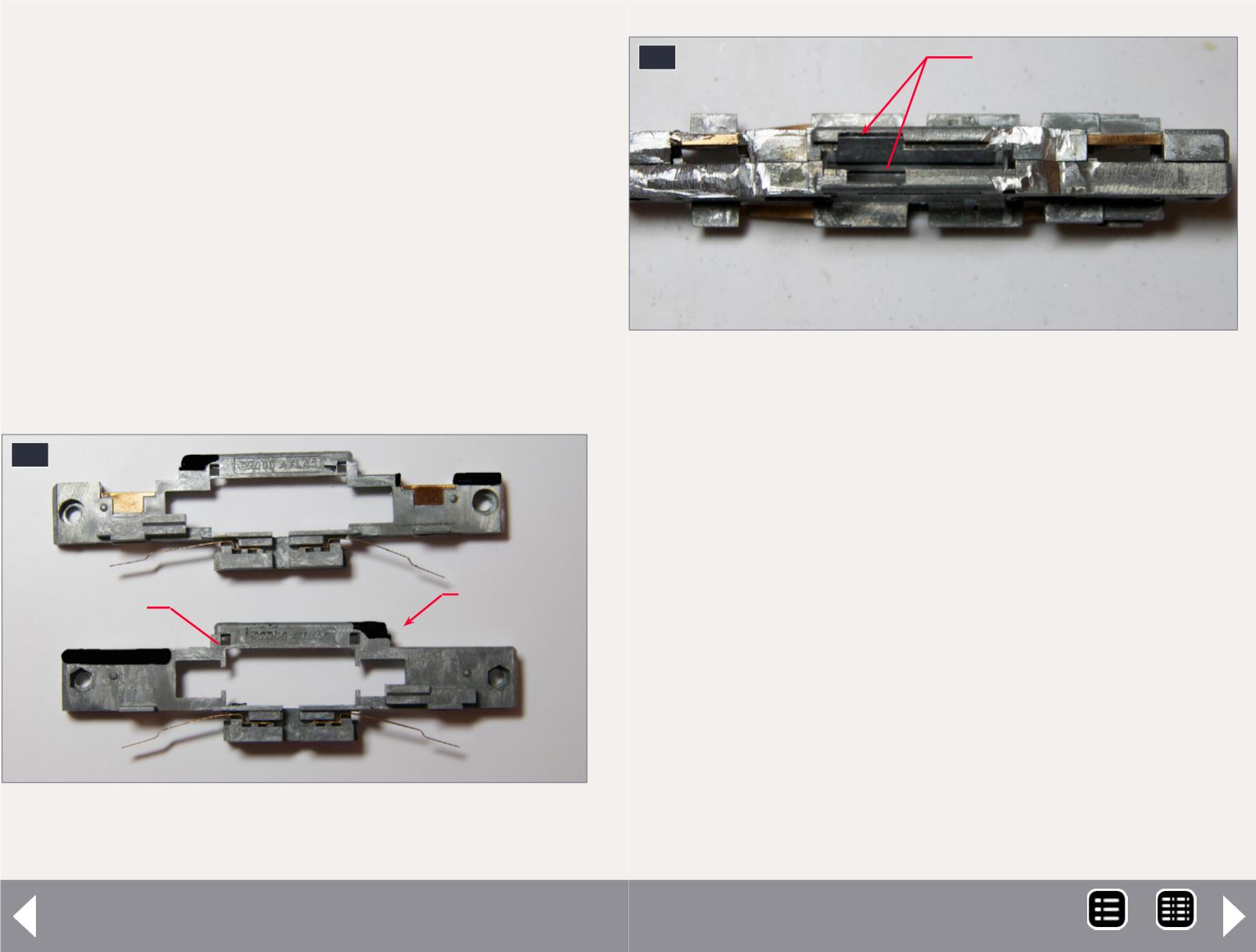

18. The black areas show where the frame needs to

be milled.

N scale sound - 7

Don’t cut to close to the fly-

wheel cutout.

Be careful cutting

around this hole

19

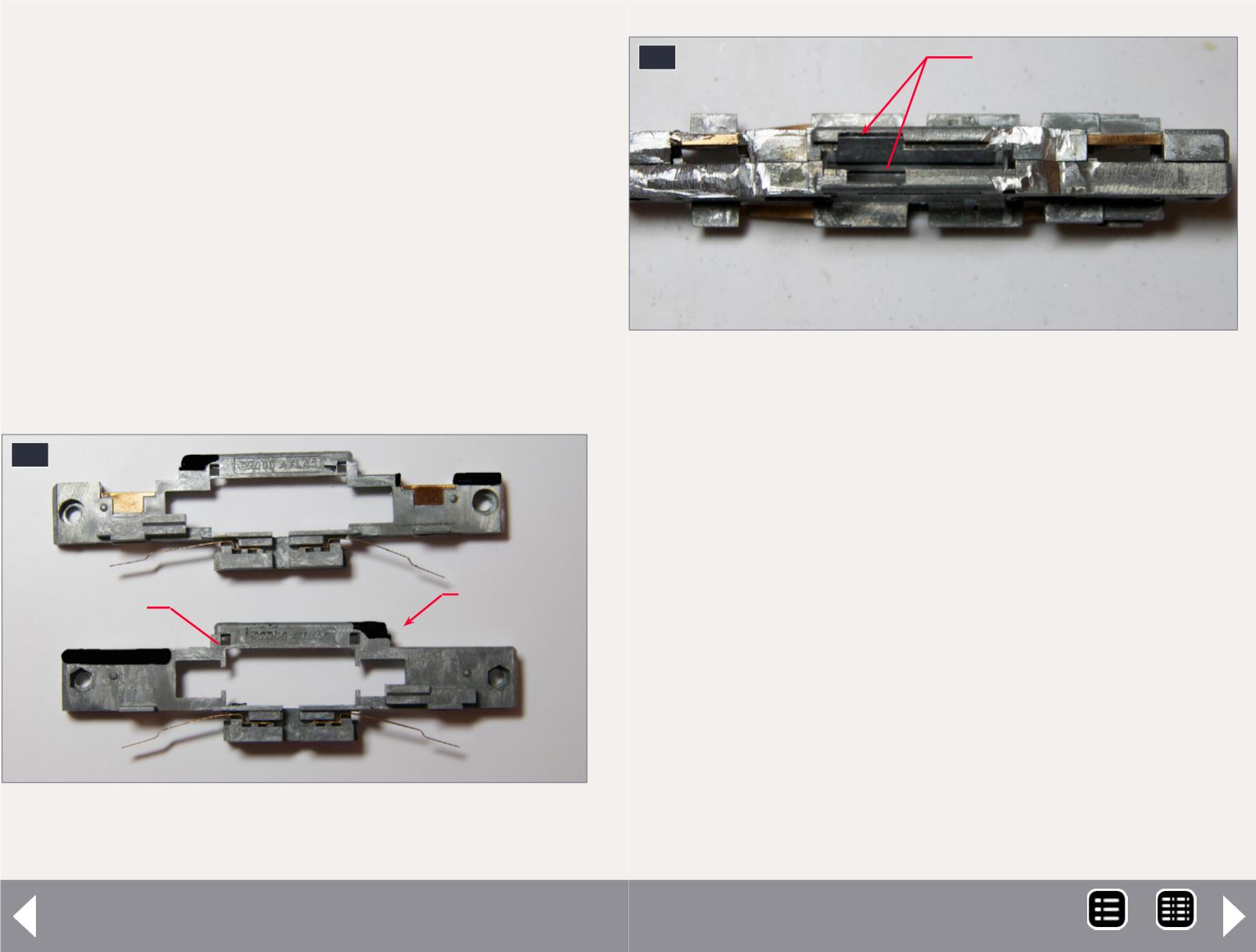

19. The milled frame showing the locations of the

Kapton tape.

Place Kapton tape

around these openings

MRH-Dec 2014