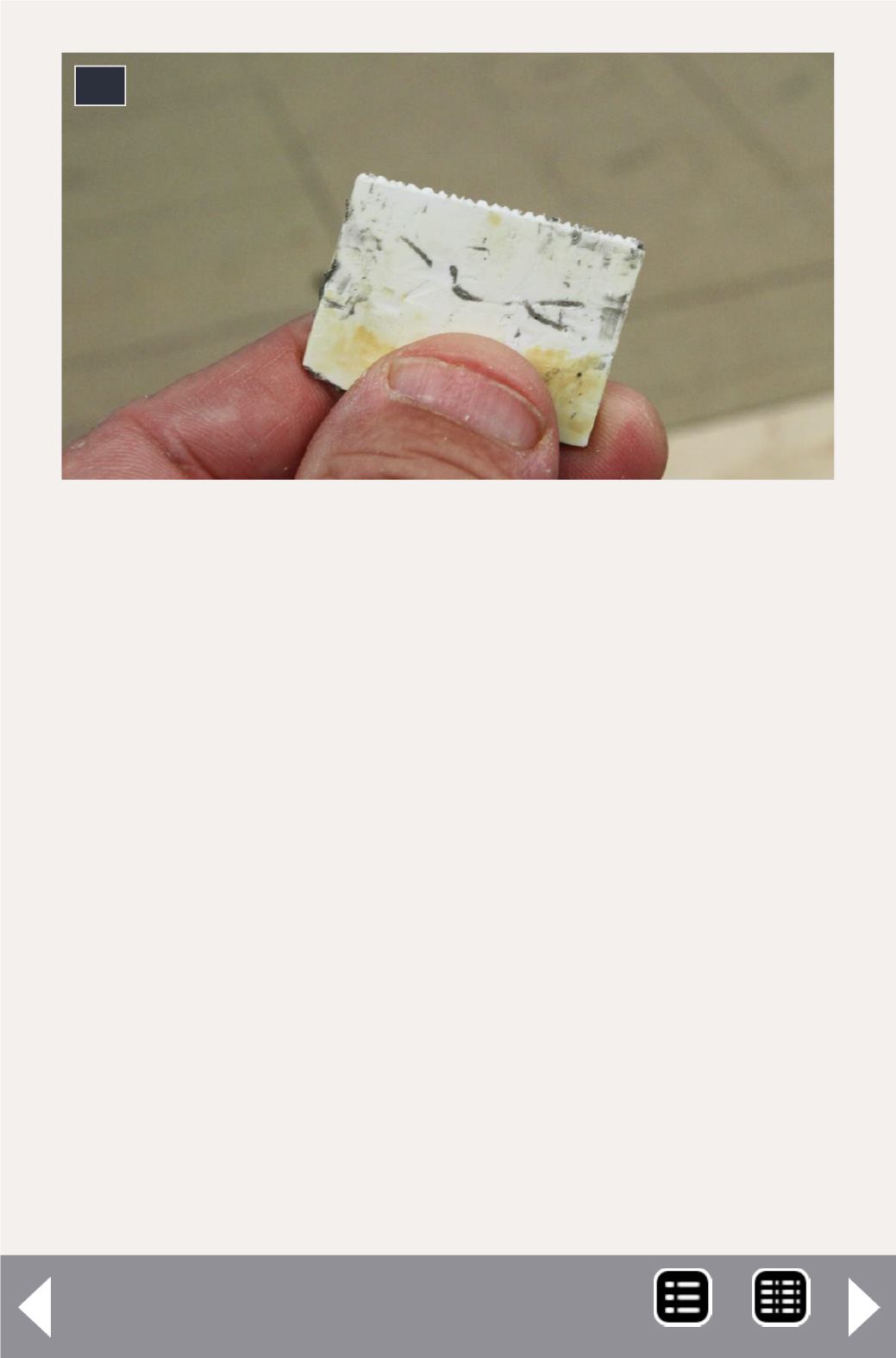

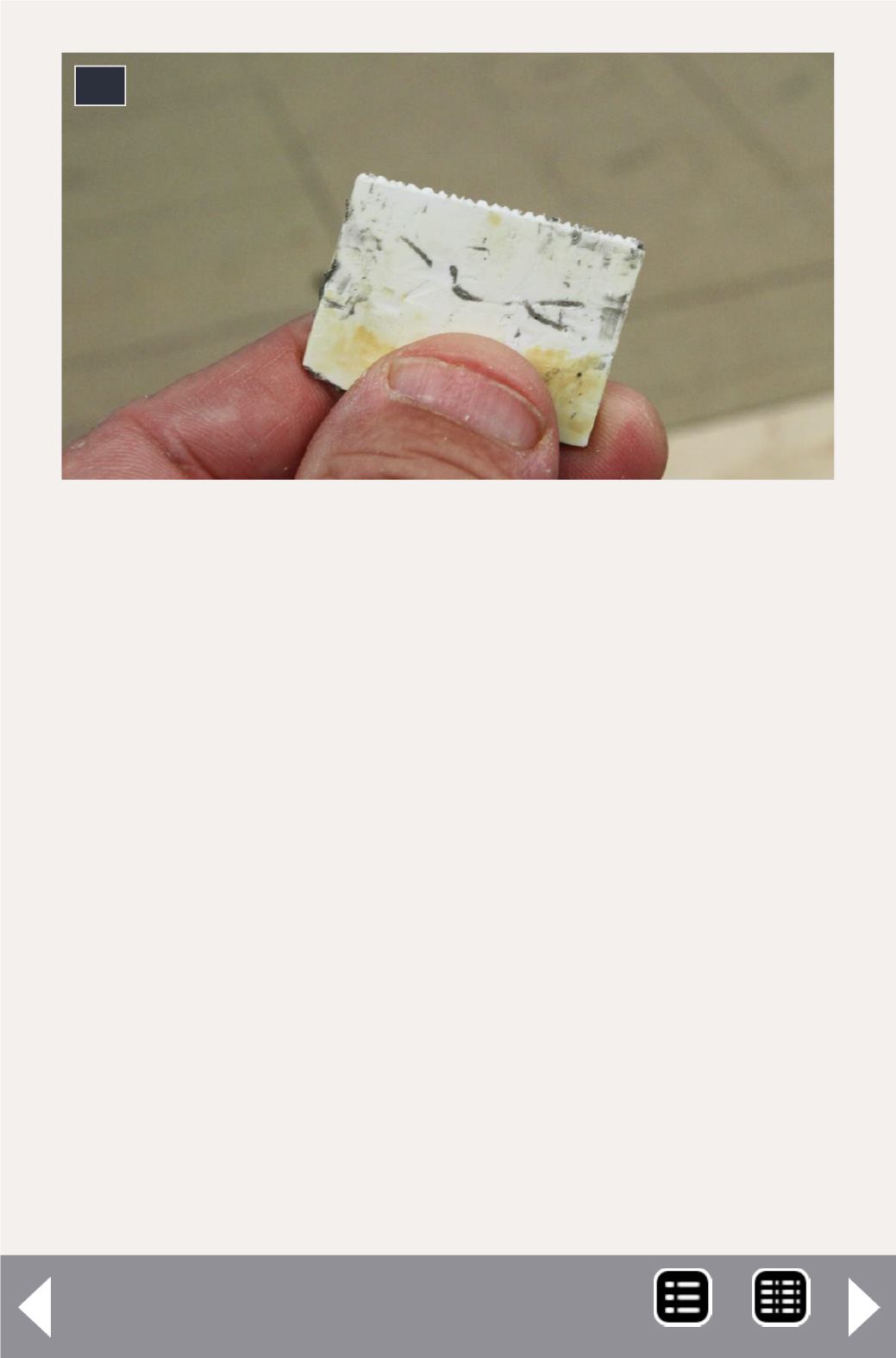

14. I use this homemade itsy-bitsy notched trowel to

spread caulk. After almost 15 years of use, it may be

getting to be time to make another one. It started as

a small scrap of .060” styrene. I sharpened one edge

like a chisel, then made notches with a tiny triangular

jeweler’s file.

14

feeder wires or go past the ties at the end of this piece of flex

track. I clean any excess off the sides of the cork.

Bedding flex track in caulk

Once the caulk is spread, I push the feeder wires down until

their 90

o

bent tops are on top of the cork and slip the end of

the new track into the adjacent track’s rail joiners. Then push

the track into the caulk. Don’t wear long sleeves while doing

this. You’ll likely end up with gray caulk all over ‘em.

Then I work the track with the MLR track tool, finalizing its

alignment while pressing it into the caulk. This is a place where