Up the Creek Column - 7

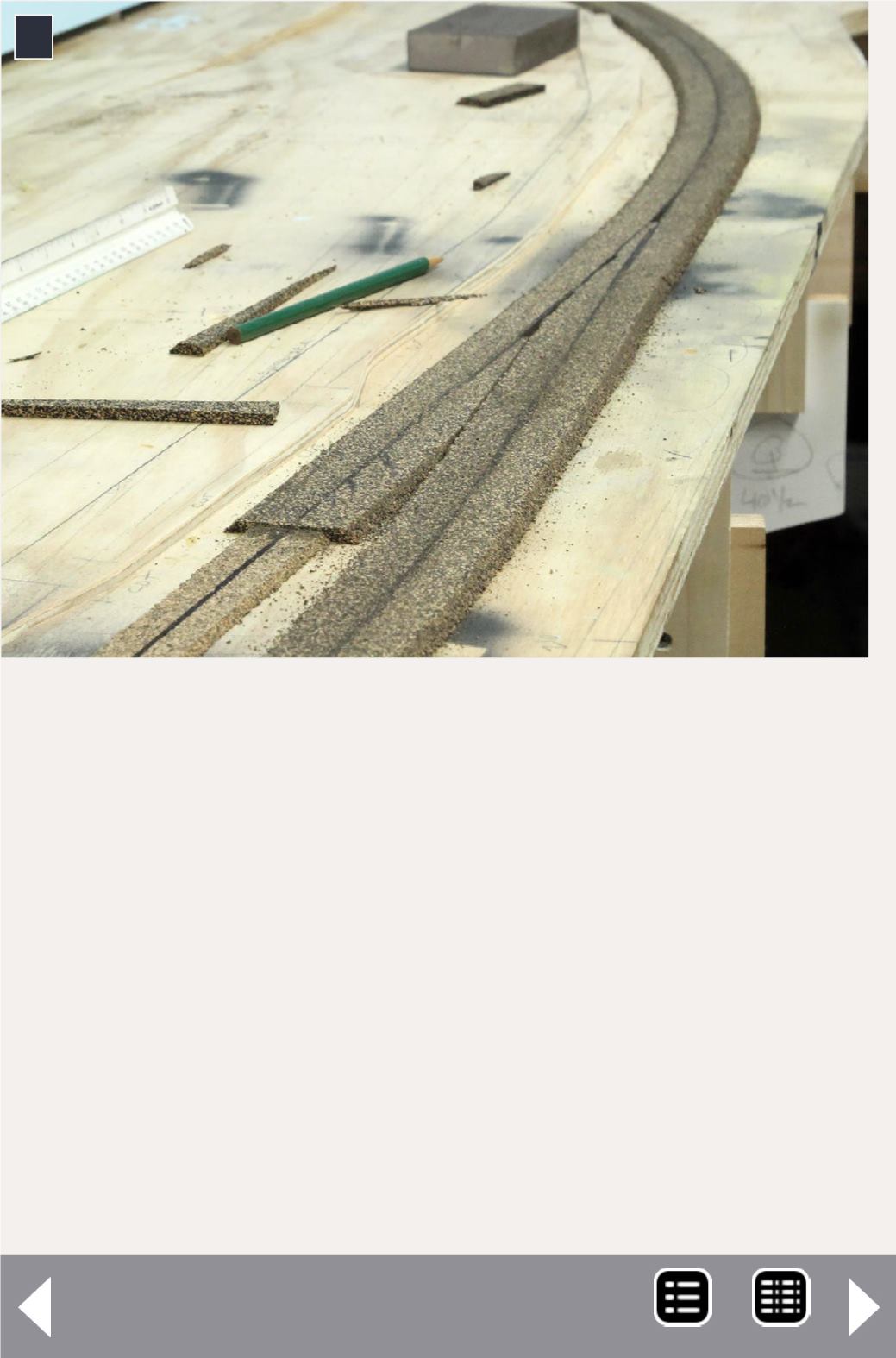

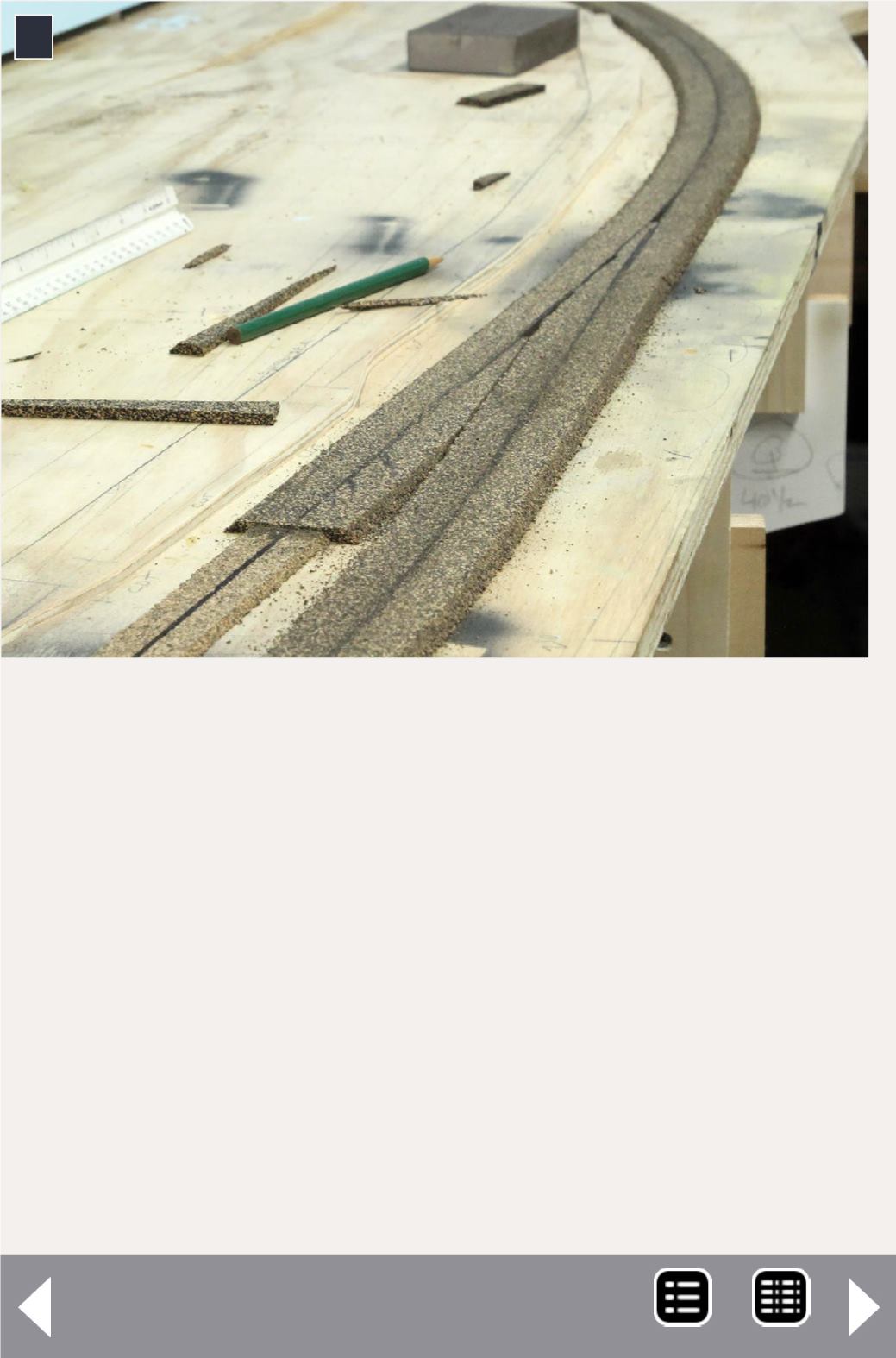

8. The center seam in the cork roadbed is clearly visible

even after the cork has been sanded.

8

I like to solder two pieces of flex track two pieces of flex track

together – 6’ long double pieces reduce the number of unsol-

dered rail joints. I work on a 6’ piece until I get it curved to

approximate shape. Then I put it in position and use the center

seam or a track center line as a guide and tweak it into shape.

I line up the new track with any previously laid pieces and work

on getting the rail ends to mate smoothly. I almost always need

to do some trimming. I use flush cutting nippers to cut the rail.

Cutting with nippers always leaves sharp edges behind. I care-

fully file these smooth. If I don't, the tight-fitting ME rail joiners

hang up and refuse to slide over the rail ends. If this process is

hard to visualize, check out the video accompanying this article.

MRH-Sep 2014