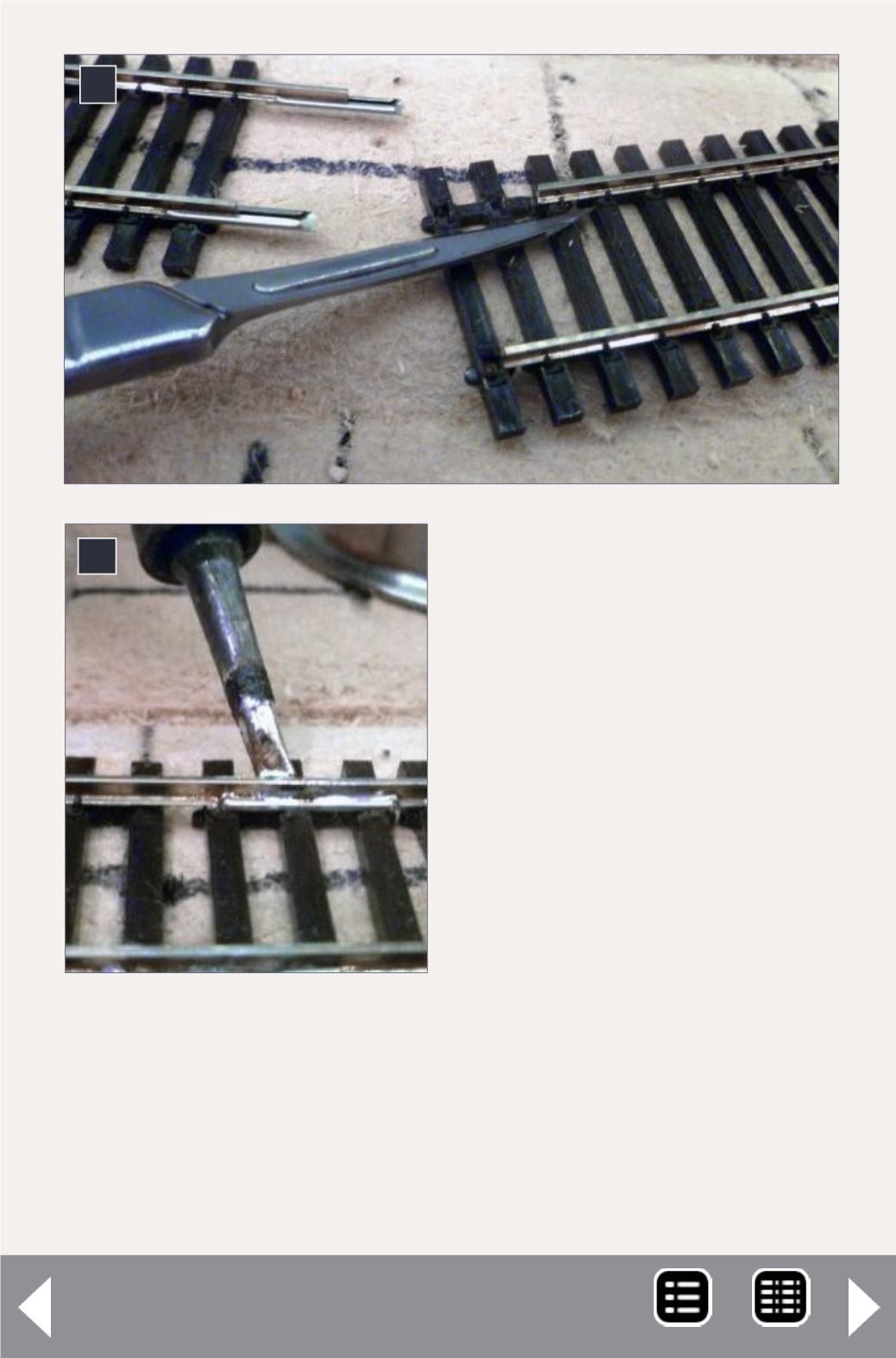

The next step is to slide the rail

joiners in position, and then

solder the joints. Soldering

ensures a good electrical

connection. I have done this

on all my layouts for years.

Even in an unheated garage

in California, where the tem-

perature has gone down to freezing in winter and above

100° in summer, there were no problems with expansion and

contraction.

My friend Marvin showed me a great tool for cleaning the tip

of a soldering iron. It’s a container [10] with a ball of brass

wool. It cleans the iron well, without cooling the tip, as a

9

8

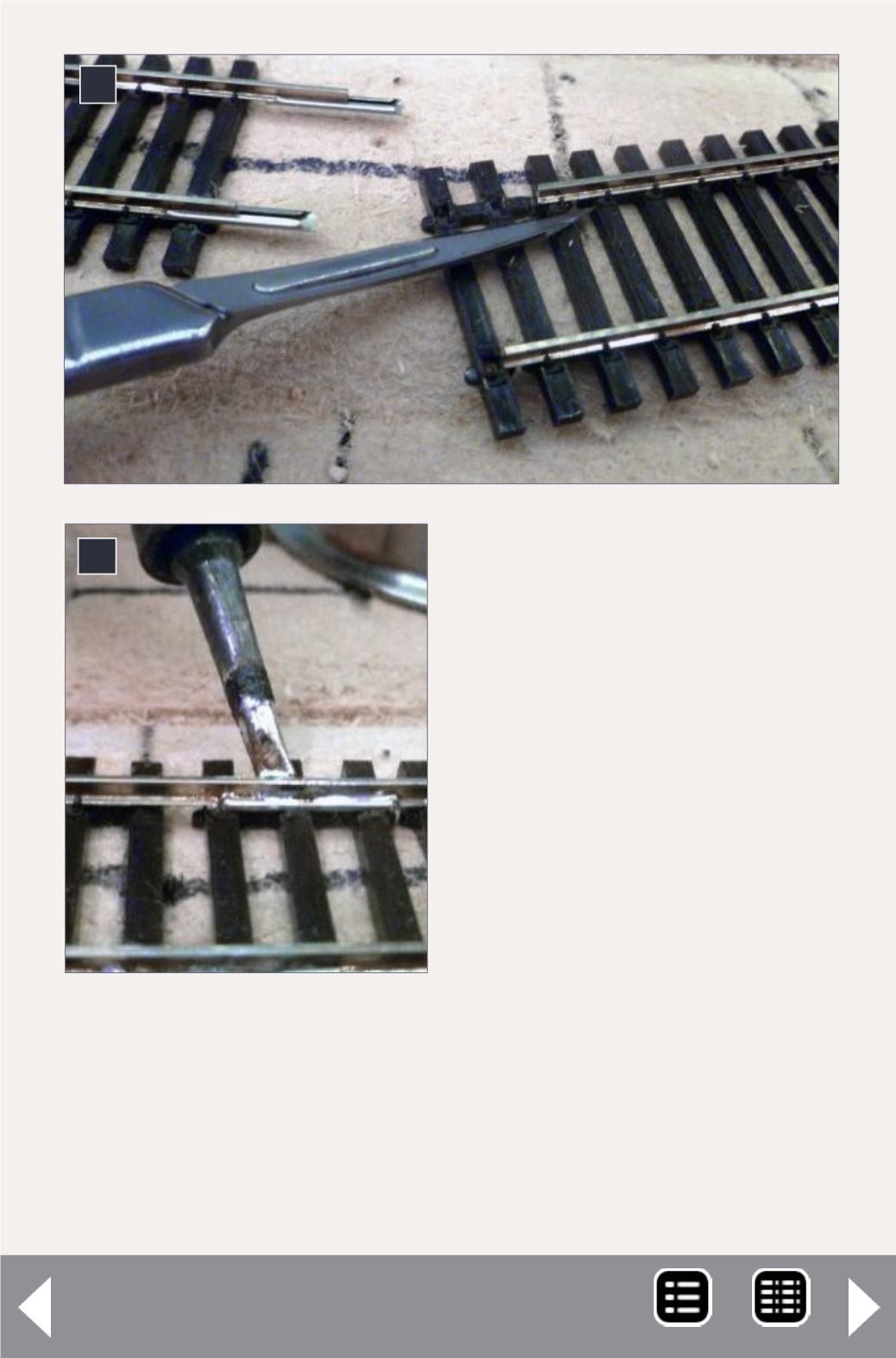

8. Trimming spikes for the

rail joiner.

9. Soldering the joint.