After the window casting fits the opening, use a small machin-

ist's square to make sure that it is plumb (vertical).

If there is more than one window on that side of the building,

place a straight edge along the bottom of the window castings

to make sure that they are all level to each other [7]. Unless the

castings all fit tightly, I clamp the straight edge to the building

wall while spot gluing them at the top of each window to make

sure that none of the castings move out of alignment. I then

remove the straight-edge and finish bonding them in place.

While doing the photos for this article, I checked how long it

took to complete a window opening from start to finish using

a nibbler. Without rushing, it took just over a minute to “drill”

and carve an opening for the nibbler head, and the same

6

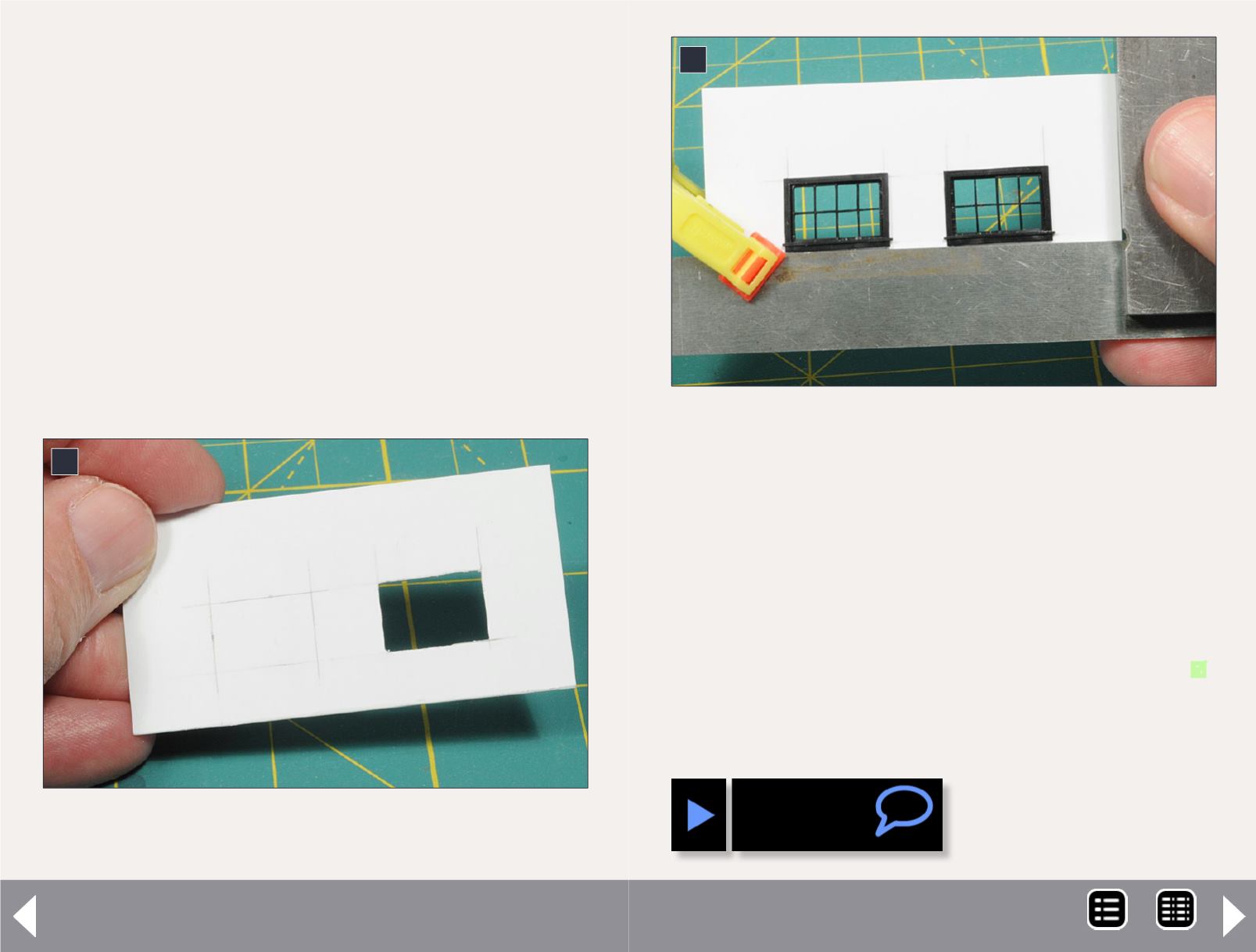

6. This photo shows the resulting hole for the first window

casting.

The Tool Shed - 4

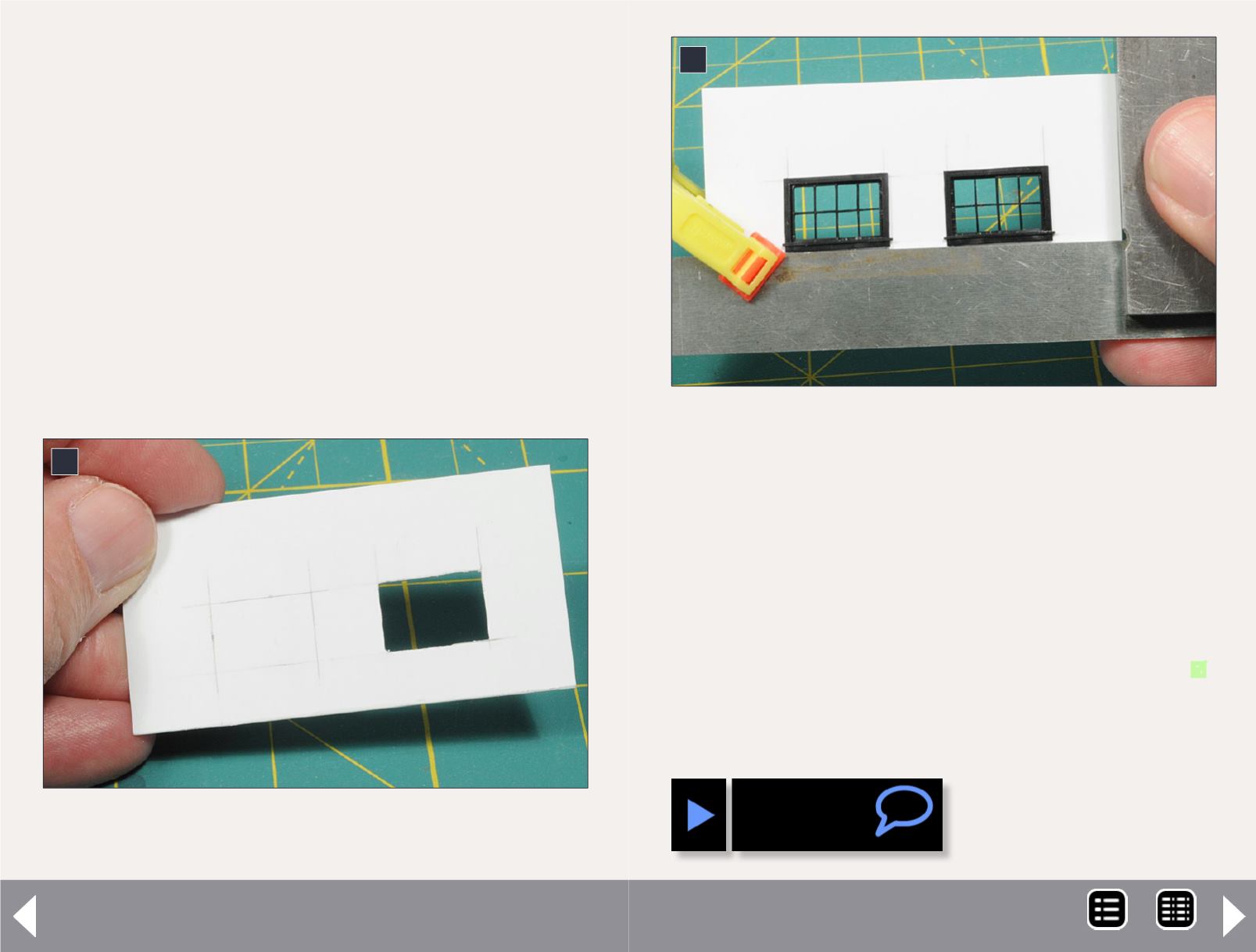

7

7. When using more than one window casting, use a

straightedge to make sure they are all level and aligned.

amount of time to insert the nibbler and cut out the opening. It

then took just over a minute to fine-tune the opening to allow

the window casting to fit. All together, it took about 3½ min-

utes total per opening.

While this method won’t work for every building, it is a quick

method for cutting out openings for windows with exterior trim.

Disclaimer - I love good tools and don’t hesitate to invest in them.

MRH-May 2014