Questions, Answers & Tips - 3

trouble on several layouts,” said Norm. “ . . . I can tell you this

– the Midsouth Model RR Club in Baton Rouge tried to switch

over, and they found that the scale couplers gave problems even

when mating with each other, and even worse when mating to

#5s. Ultimately, they pulled all the scale couplers and went back

to #5s.”

One issue is the reduced height of the scale coupler versus

the old standard #5, and changes in track gradient [3a-3b]. “I

had a rather abrupt angle ‘going up’ when I had some differ-

ent sizes, and things drifted apart,” said Steve in Iowa City. “A

slow speed-up in that area revealed the smaller head lost grip,

literally coming up and off the other. It was a Kadee PS-1 box-

car with scale, smaller-head couplers and a larger Kadee #5 (I

think). A slight adjustment to my riser under that area of track

fixed it, but beware. I needed a more graceful and gradual tran-

sition from one grade to another, and it actually looks and runs

all cars better, so it was a hidden blessing.”

WSOR Engineer Mike set up a Kadee coupler-height gauge

with a #58 and makes sure the mounted scale coupler lines

up exactly with the gauge. “The smaller head leaves no room

for error,” Mike explained. “On the equipment I primarily use

on my table at home with 18” radius turns, I generally stick

with a #5 on everything. The greater gathering range helps out

on the tight turns. The table is flat, so no issues with vertical

separations.”

Santa Fe Willie reports no problem once cars are coupled

together, and no problems uncoupling using either a skewer

or a Rix magnetic uncoupler. But he does experience problems

coupling up, even on straight level track. “I have to occasionally

use the skewer to open the jaws of the scale coupler, or make

two or three attempts,” Willie reports.

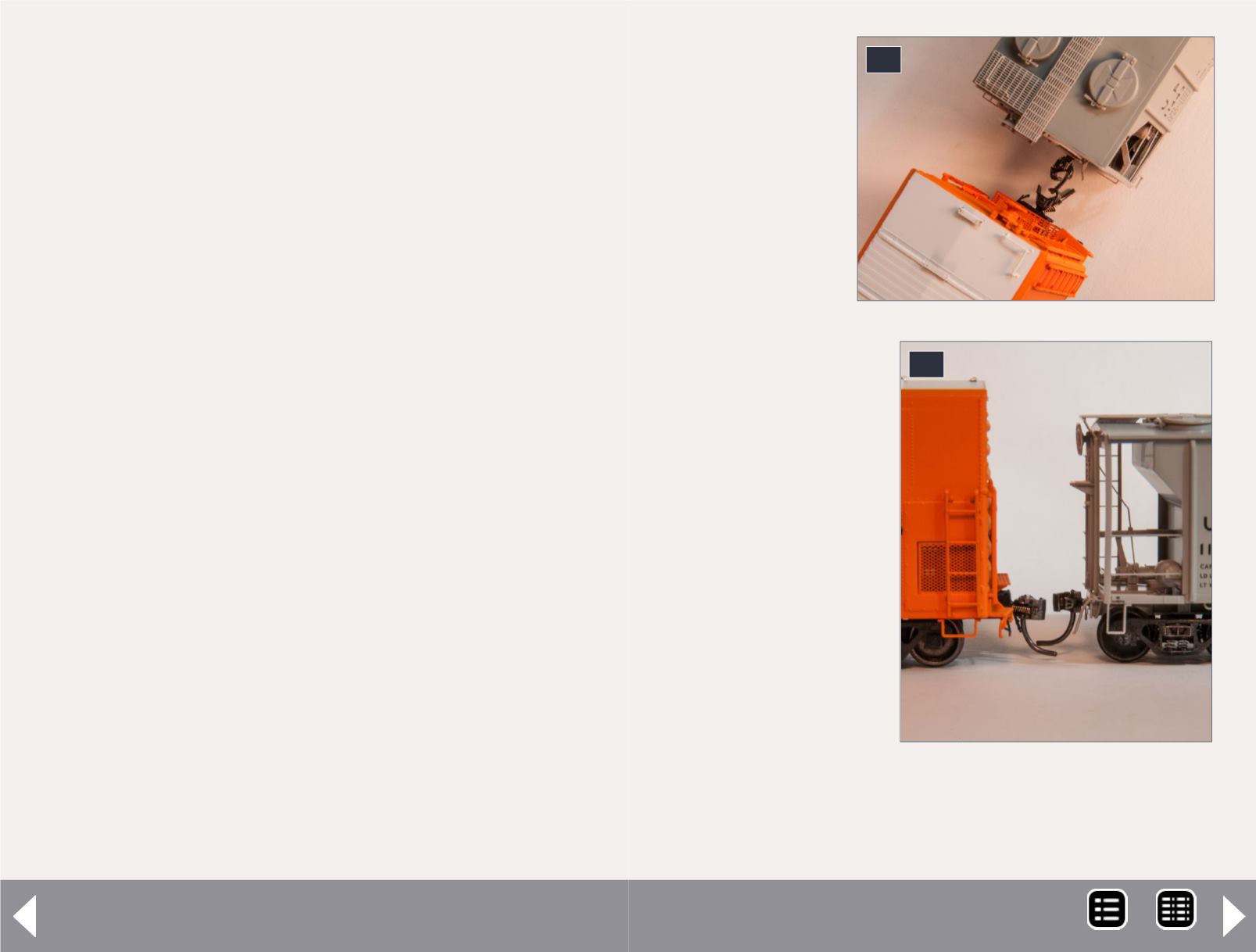

3a-3b. From above,

note the narrower

face and smaller

knuckle opening of

the #158 coupler

compared to a #5.

Centering is much

more critical with

close-to-scale size

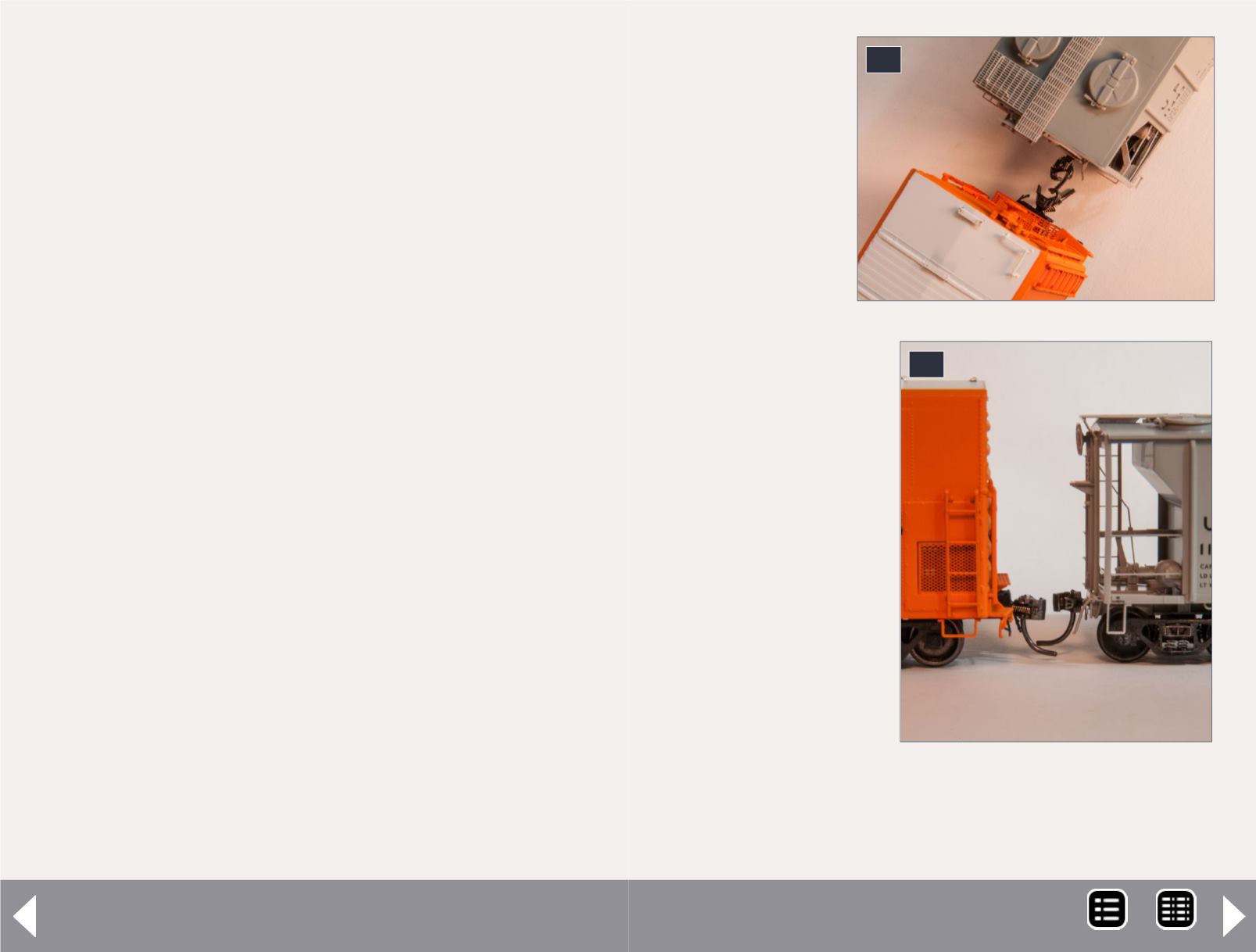

couplers. From the

side, see the differ-

ence in knuckle height of the two styles. Bumps in track

can make couplers separate unless both are installed at

the exact correct vertical height. Note the offset in the cen-

tered horizontal mold line in the two couplers.

3a

3b

Russ Bellinis’s

experience is “the

track work has

to be perfect to

use them. If you

have any dips and

bumps in your

track work, you

will experience

nuisance uncou-

pling. The track

work and coupler

heights must be

good with #148s

(#5-size with an

integral spring),

MRH-May 2014