Batch-building freight cars 101part 2- 14

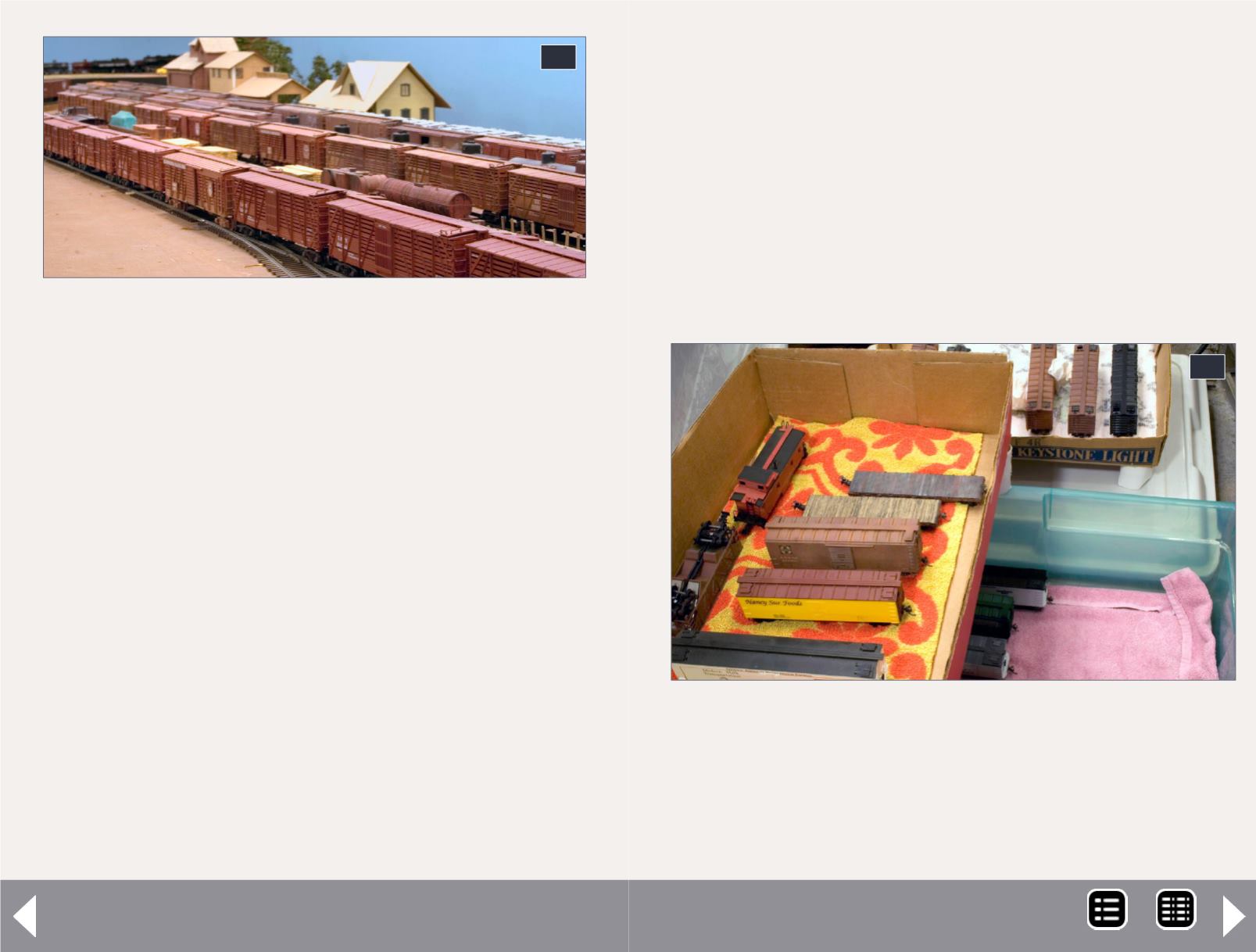

56: This yard is cloggedbeyond capacity.Most

modelerswill find eventually find themselves in this

situation if rolling stock acquisition andbuilding

activities continuewithout any limits. To keep the

layout functional, a rolling stockmanagement and

storage planwill eventually have tobe implemented.

56

1.Determinehowmany carswill fit on the layout

comfortably.

2. Count the cars currentlyon the layout.

3. Decidewhichoneswill stayandwhichoneswill go.

4. Figureout how to store theexcess.

Layout capacity:

1. Take stockof your sidings and staging. Howmany carswill

fitwithout clogging the railroad topoint of gridlock?Make

a chart andfigureout the capacityof the layout.

2. What trains areyou running, and inwhatmanner??

Operators: Thoseof uswhohaveoperations-based

layoutshopefullyhavedone the calculations, andknow

roughlyhowmany cars areneeded to run theoperation

scheme, andhavemadeaplan toaccommodate these

carson the layout, or tomove themoffandonasneeded.

Railfans: Decidewhat trainswill run, howyou like to

run them, andwhere theywill be stored.

Display layouts:Maybea through trainor two,with the

rest of the rolling stockout on sidings for viewing. How

bigare the sidings?What cars are to set out for viewing?

Wherewill the through trainspark?

Clubmembers: Howwill you transport your rolling

stock? Is thereaplaceat the club to store the carson the

layout andoff the layout?

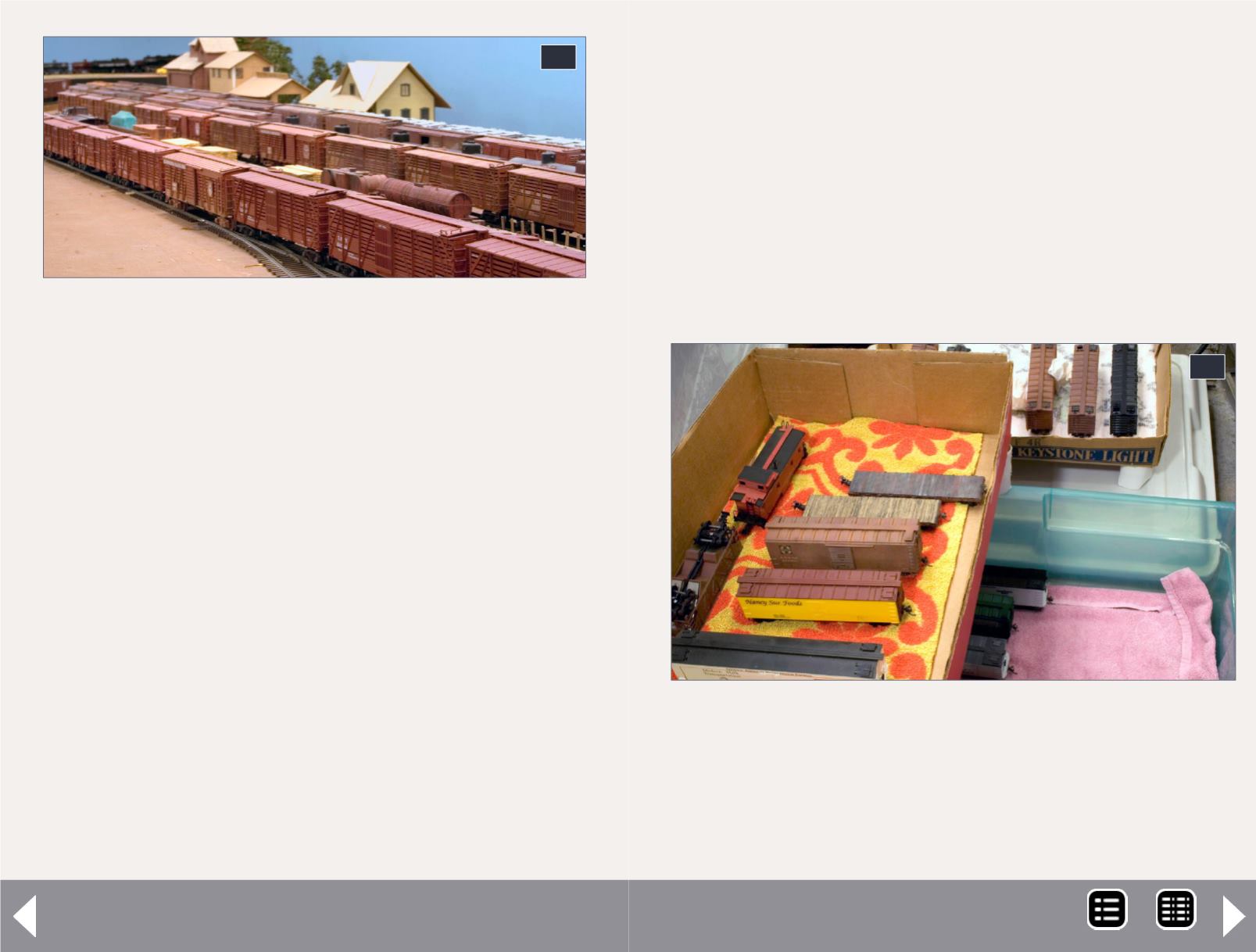

57: Plasticbins arefittedwithpaper box lids that fit

insideoneanother tomaximize storagecapacity. All the

cars are stored in trays standingupright.Notice there

are two trays that fit in thebin. Binsmust bemoved

carefully toavoidbanging thecars around inside the

container. This isnot ideal solution, but itworks.

57

MRH-Apr2014