STEP 3: Lubrication

STEP 2: Electrical Improvements

Continued ...

1970s Santa Fe SD45 - 3

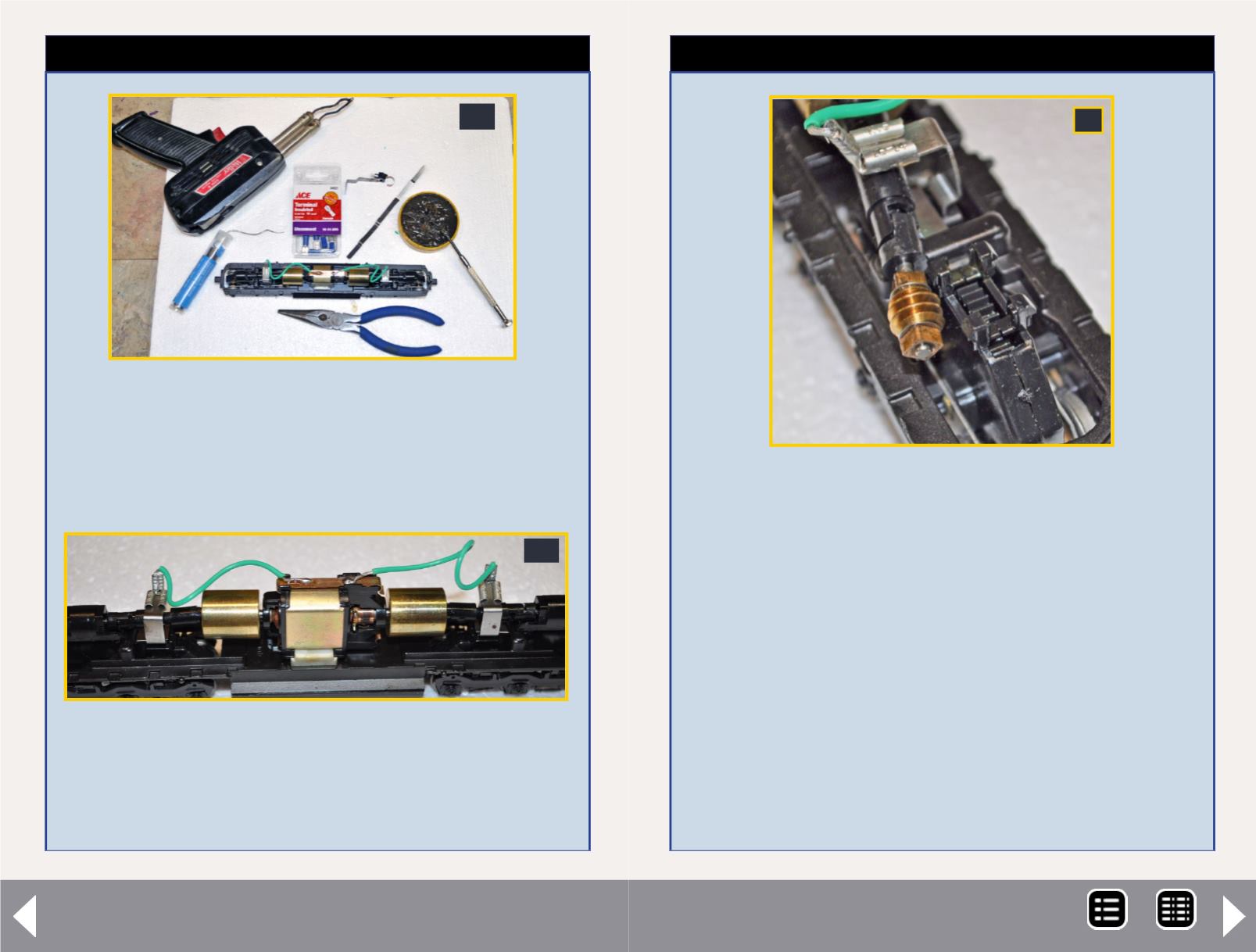

2a

2a: Here are the tools I use, along with the discarded

parts. From left to right: a solder gun, solder, insulated

terminals, pliers, soldering paste, jewelers flat head

screwdriver, and some wire to reconnect the power from

the motor to the trucks.

2b

2b: I attach the wire to the terminals and solder the wire

to the positive wire on the motor as shown in the pic-

ture. The terminals slide onto the truck clips. The nega-

tive connection is made by the metal clip on the motor

bottom that contacts a polished spot on the frame.

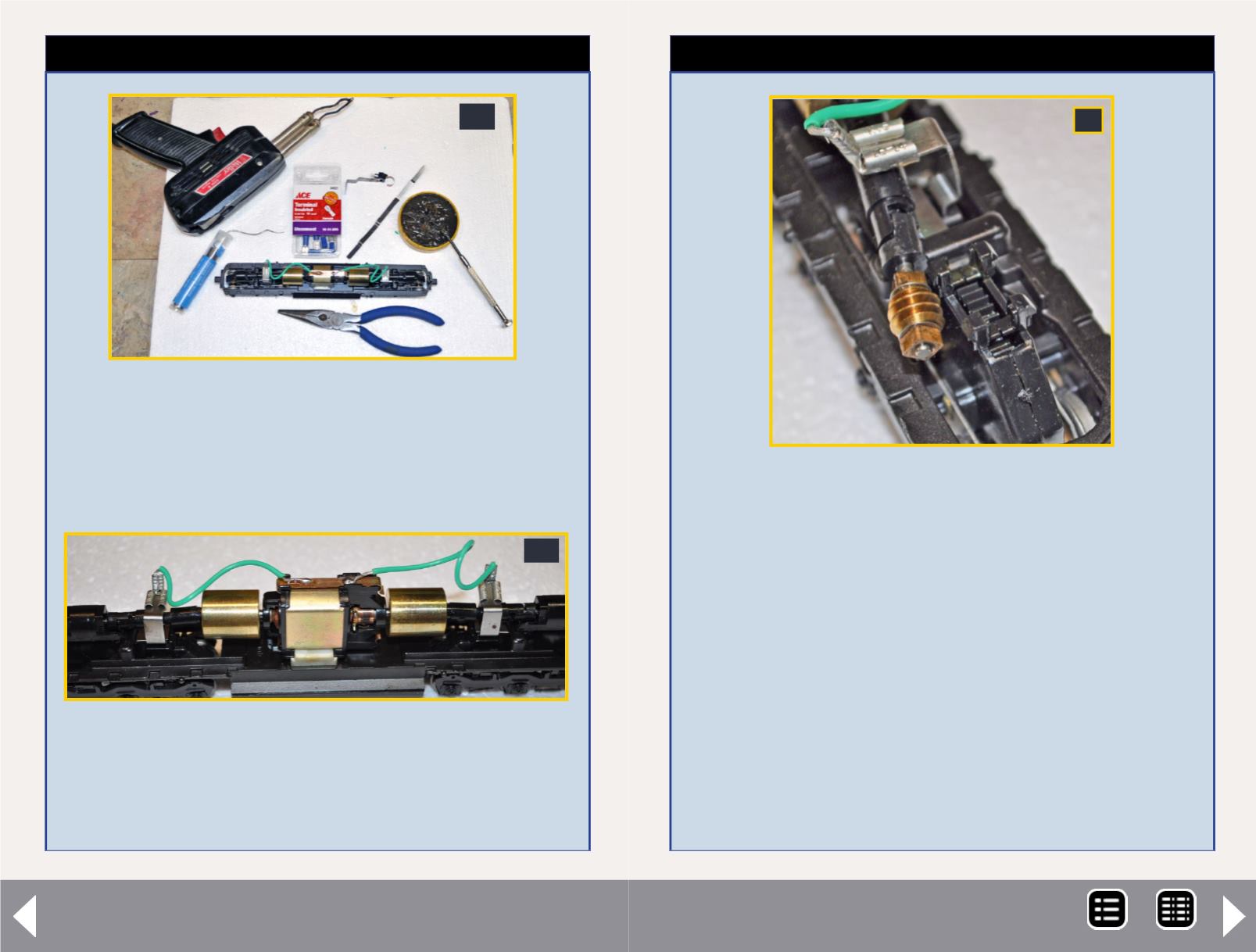

3

3: Remember the Athearn “growl”? You can tone this

down. Carefully pry off the gearbox cover on each truck.

I have used Vaseline for years with no problems for this

step. If you are not comfortable using Vaseline, apply

a plastic-compatible grease to all of the gears you can

see. Put in a large amount. Apply it to the metal drive

gear also. Put the unit on your track and run it back and

forth a few times to work the grease through the gear

system. Apply more if unit continues to growl.

Another method to reduce the “growl” is by cleaning

out any flash in the gears, and by reducing the end-

play in the worm gear with NWSL washers (see photo

above). This method is more involved and requires

further disassembly of the trucks. If grease alone

doesn't solve it, use this method as a last resort.

MRH-Jan 2014