With high frequency drive came another issue. When a motor

is driven at a high frequency, it loses torque at low speeds,

making the start-up issue worse. Again technology came to the

rescue, when decoder manufacturers added pulses or shifted

the frequency of the pulses as the motor started. Train Control

Systems (TCS) was one of the pioneers of this technique, which

they called dither. Digitrax calls it torque compensation.

Another technique was developing a following. Using the Back

EMF (reverse voltage) developed by the motor, a BEMF style

decoder

is able to sense the

motor speed during the time that the decoder is not driving

power through the motor. Being able to sense motor speed allows

the decoder to track trends, such as slowing down, and correct for

them. Modern sound decoders, in addition to motor control, use

this BEMF data to adjust sounds for load, chuff rate, etc.

Getting started with DecoderPro

I highly recommend DecoderPro (see my July 2012 column:

for this tweaking. Every

time I mention DecoderPro, or some other aspect of JMRI, I try

to remind folks to donate to the cause. Even a $10 bill a year

from all the users would make a huge difference. Do so now,

while you are thinking of it. Just click on the link:

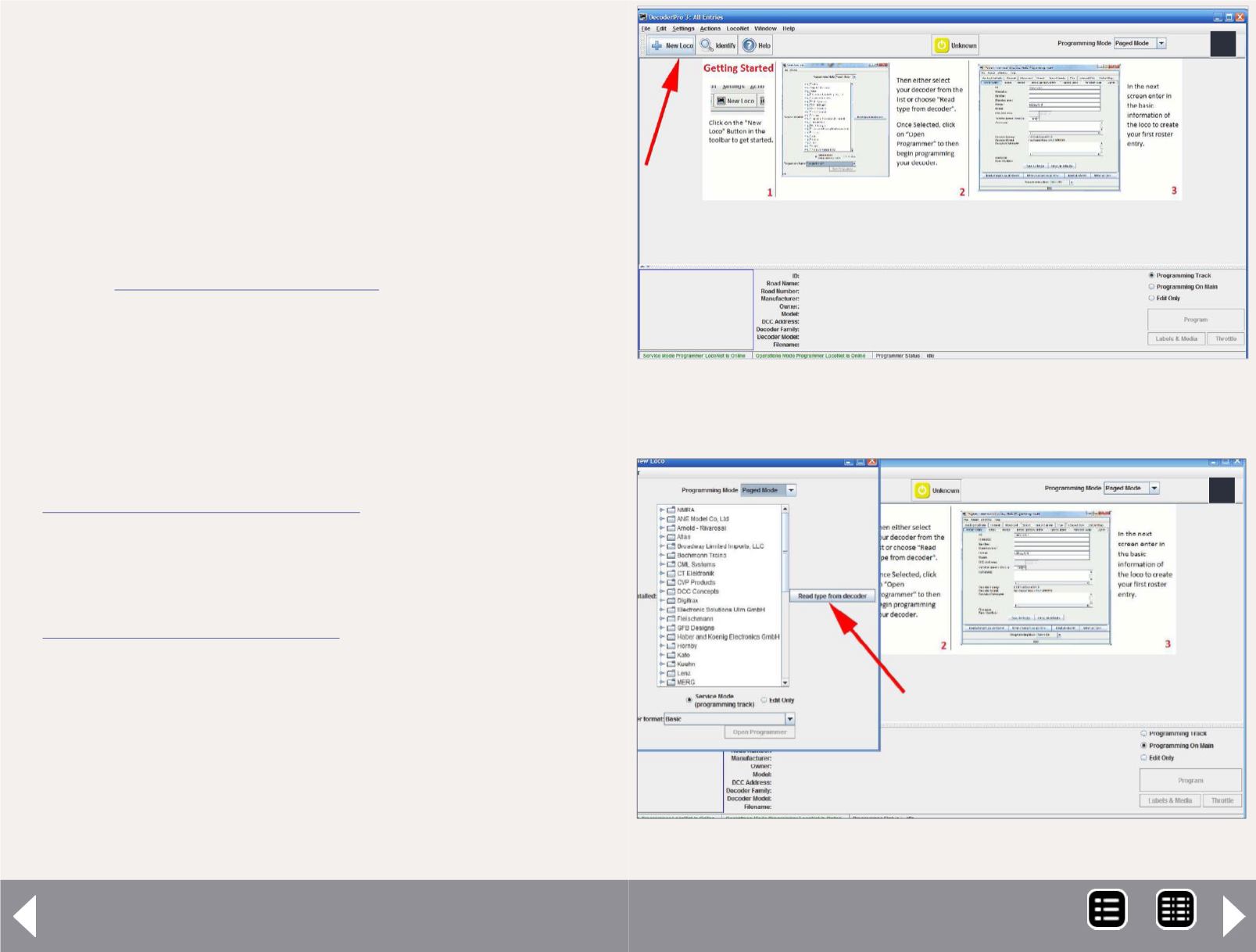

Assuming you have done nothing with DecoderPro before,

you start by putting the loco on the programming track. Open

DecoderPro. Select NEW LOCO (3).

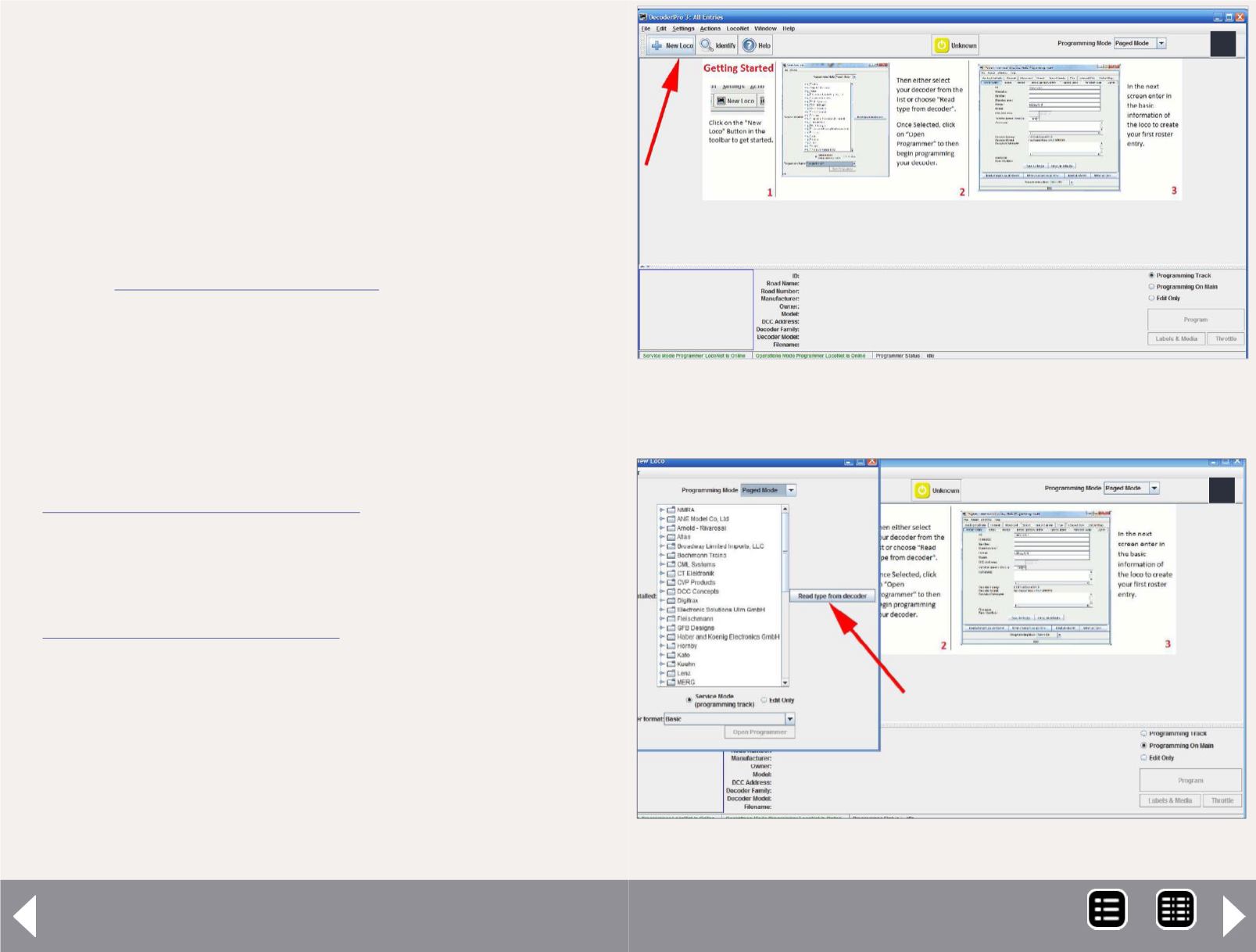

Then READ TYPE FROM DECODER (4).

Once you have the decoder selected correctly, make sure

COMPREHENSIVE display mode is selected and open the file in

the PROGRAMMING TRACK mode.

DCC Impulses Column - 4

3: DecoderPro screen: Starting a new loco with the

NEW LOCO button.

3

4: DecoderPro screen: READ TYPE FROM DECODER.

4

MRH-Dec 2013