Shoofly free-moN module - 19

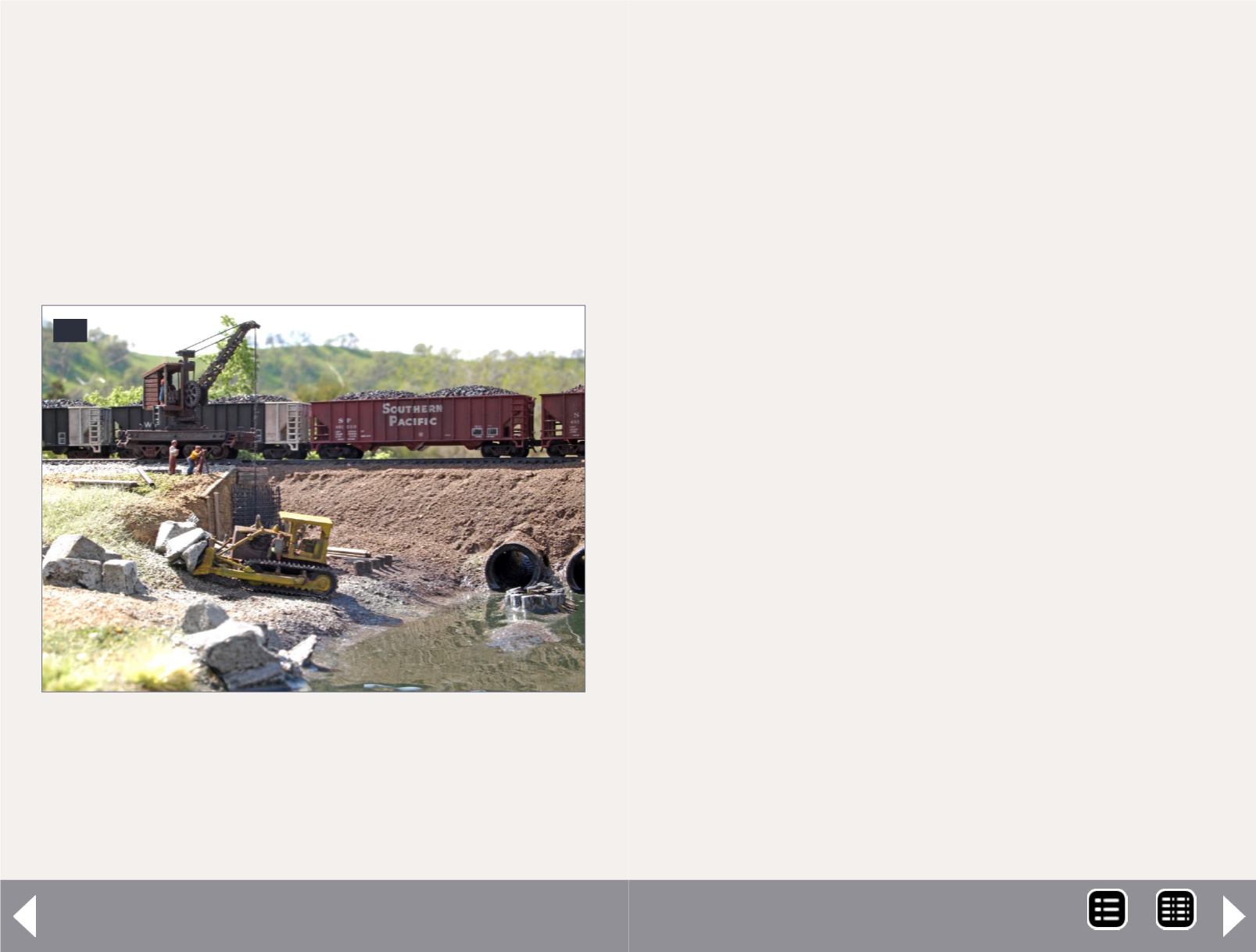

abutment, workers removing the wood framing of a finished

abutment, and a surveying crew aligning both abutments while

a bulldozer clears the miscast concrete chunks. (27)

I scratched the finished abutment out of styrene, while the

crumbled remains of the miscast abutment are the crumbled

remains of balsa foam with some wire and screen mesh pieces

sticking out. The rebar was shaped from a screen door repair

patch with a few of the horizontal wires teased out from the

top, and the forms created from stained stripwood. A Model

27

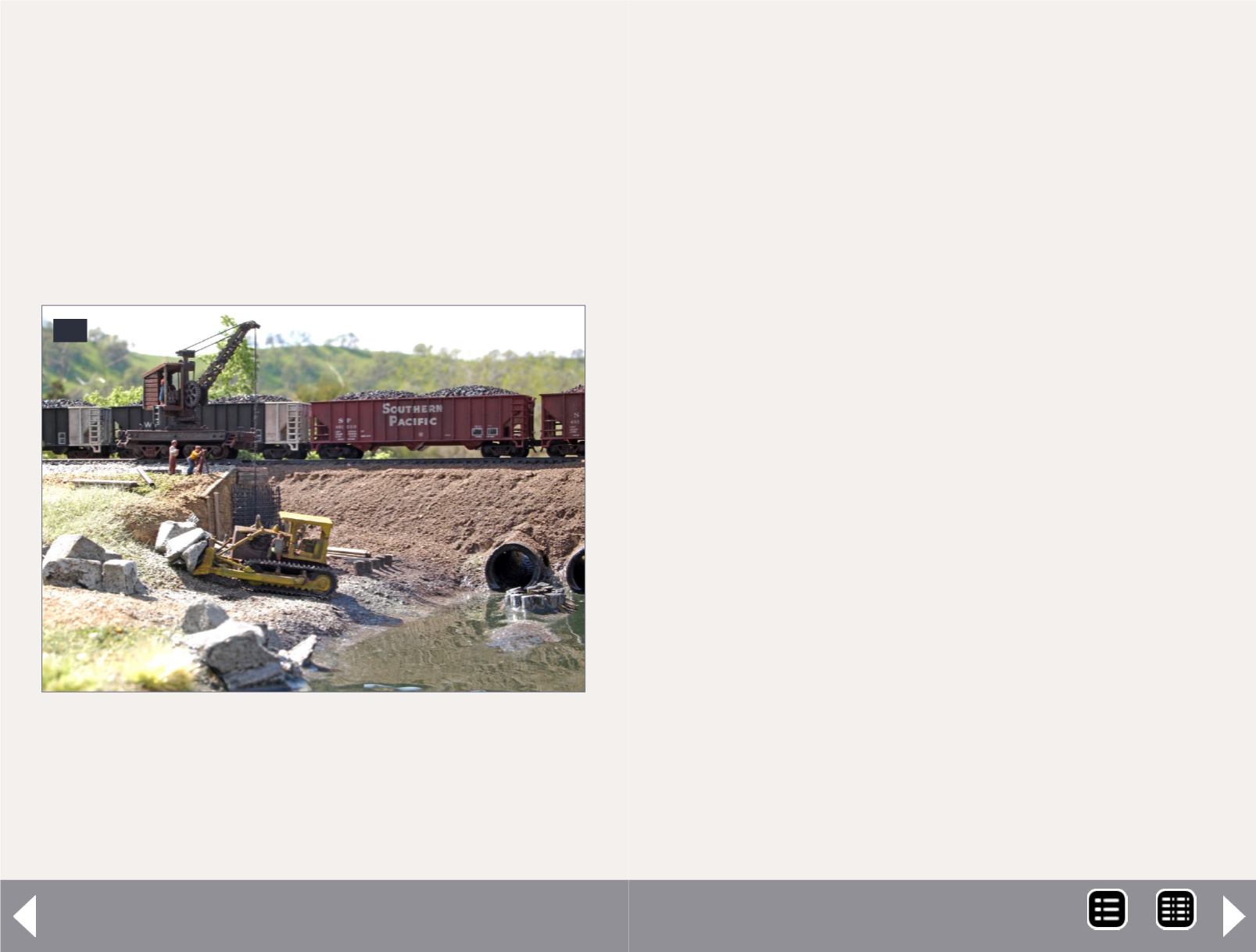

27: Each section of the shoofly scene tells a different

part of the story. The remains of the wooden trestle poke

out of the ground and water. Chunks of miscast concrete

are being carted away, rebar and wooden forms begin to

rise around the hoist crane, and surveyors ensure this

time everything will work out right.

Tech Studios hoist crane and a GHQ bulldozer provide some

mechanical muscle to help get the new bridge built before the

spring rains really start slowing things down.

The scene must be somewhat successful because, even

after explaining what’s going on and why I chose the specific

moments of tableaux, people still ask me, “So … when’s the

bridge going to be finished?”

Water

The Voice of Experience says, “Pour the water last!!” No mat-

ter what material you use for water it immediately becomes

a magnet for dust, dirt, foam, glue, static grass and any other

type of debris floating around during construction.

Or, pour a thin layer early on to mark off the water area and to

seal ground around it and then do another pour at the end of

construction to cover over any blemishes or trapped debris. I

used Magic Water, as it doesn’t smell like epoxy, doesn’t crack,

is easy to tint with solvent-based paints, and you can pour

up to ½” at a go (which is more than enough for deep N scale

water). I tinted the Magic Water with a few drops of Floquil

BNSF Heritage Green and Grimy Black, which results in a

muddy green color similar to many Northern Californian creeks

and rivers.

“No matter what material you use for water it

immediately becomes a magnet for dust, dirt,

foam, glue, static grass and any other type of

debris floating around during construction.”

MRH-Nov 2013