Let me make one important point. It often seems that model-

ers do not realize how many wood-sheathed cars continued on

the PFE roster, even well after the arrival of thousands of all-

steel cars, just because the PFE roster was so big.

For example, in April 1950, 62% of PFE cars were wood-sheathed;

by January 1958, the fleet was still 47% wood sheathed (and inci-

dentally, there were 712 mechanical refrigerator cars on the ros-

ter). If nothing else, models should be chosen with this proportion

of wood vs. steel in the car fleet in mind.

Modeling an Ice House

As I stated in Part One, describing prototype operations, most

icing facilities in PFE territory were ice transfer plants (ITP), and

many were not really

large. This permits

modeling a small icing

facility that is not out

of scale with the rest

of the layout.

In my town of Shum-

ala, I have done

just this, with an ice

house set up for rail

delivery of ice from

elsewhere, and a two-

car deck. The building

is a simple structure

of styrene novelty

siding, with a Grandt

Line window and sim-

plified doors. I show

Getting Real Column - 13

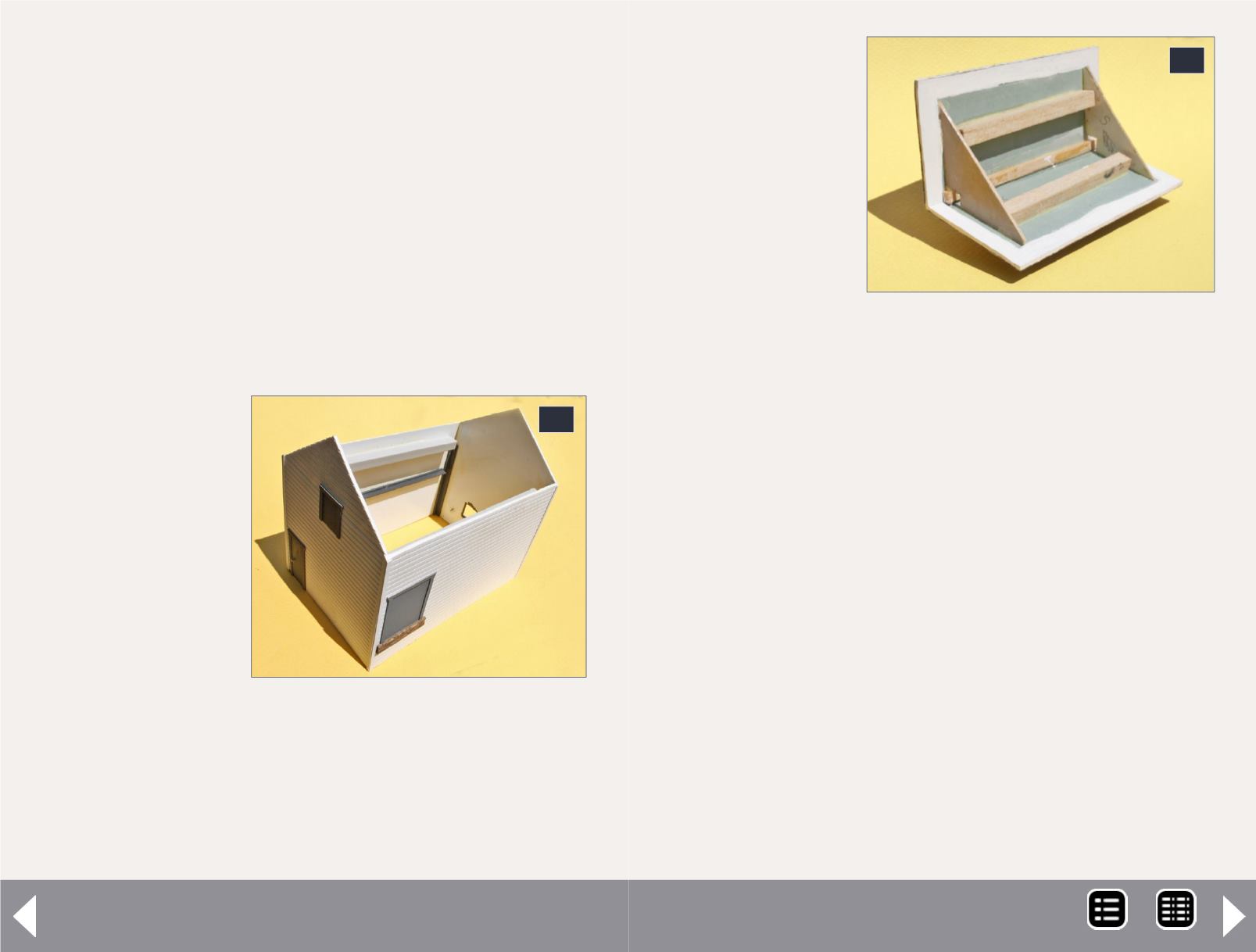

32: The styrene building is built

with novelty siding, reinforced

near the top of the sides with

square ABS ubing, and with an

angle shape at mid-height, along

with corner angles. This kind of

construction is quick and easy.

32

the inside of the

completed structure

(32) – very simple

styrene modeling.

Almost all my struc-

tures have remov-

able roofs, for future

access to replace

window glazing, add

lighting if desired,

and so on. You can

see the roof con-

struction for this

structure (33), which

is heavy cardstock

amply reinforced. I

modeled the sides of

the clerestory atop

the roof with styrene

clapboard, to sug-

gest louvers in the clerestory.

An end view of the ice house (34) shows where drive-up cus-

tomers would purchase ice. A small-town ice facility like this

would likely manufacture small amounts of clear ice for con-

sumer sale, but would have limited ability to produce ice in

the quantities needed for icing refrigerator cars around peak

harvest season.

I present an overview of the ice house and deck here (35). The

deck is entirely of stripwood, pre-stained and built board-by-

board, and supported on bents hat were constructed using a sim-

ple fixture to ensure that they would be identical.

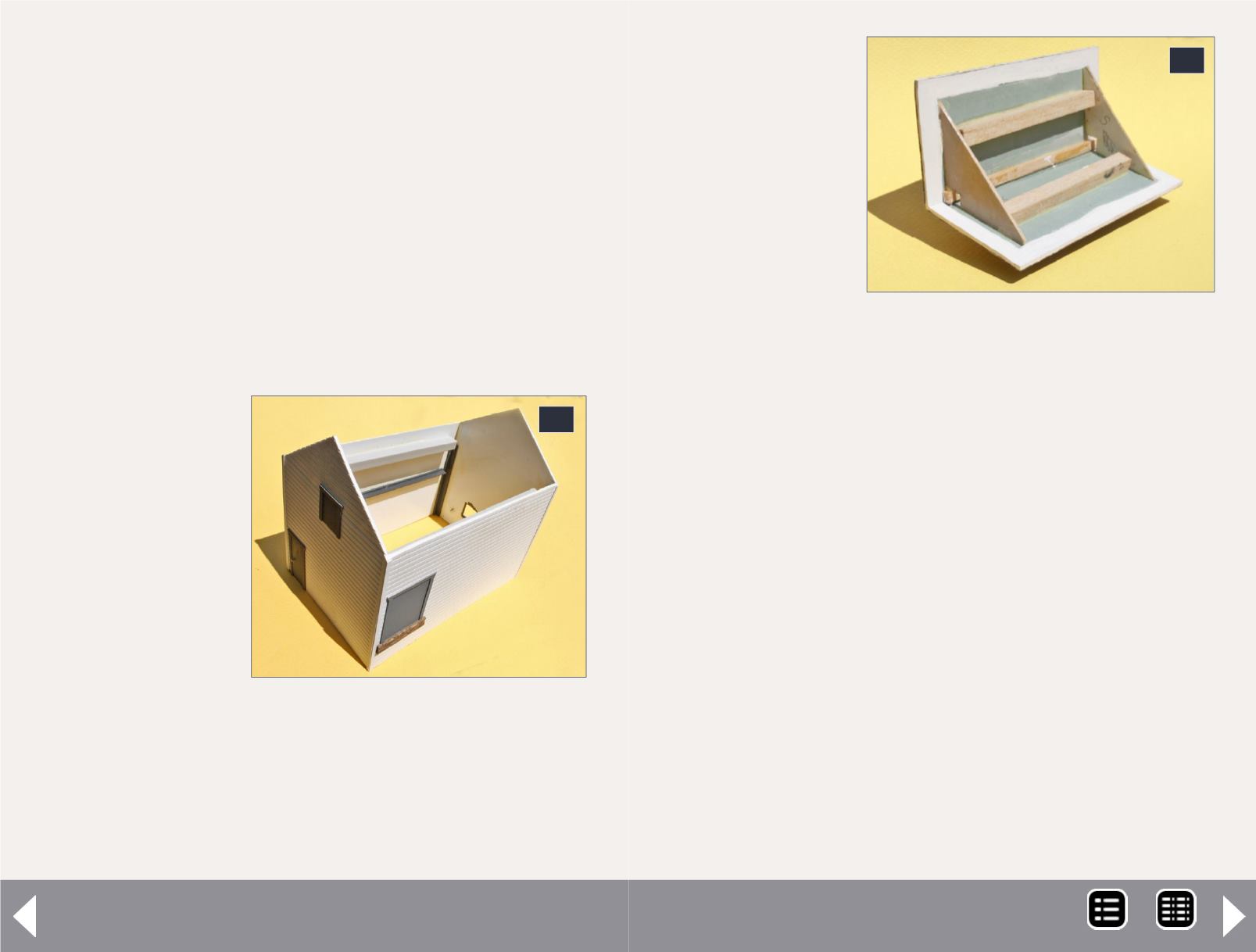

33: The ice house roof is made

from heavy cardstock, thoroughly

reinforced inside with quarter-inch

square balsa and with cardstock

roof formers to ensure matching

roof pitch with the building ends.

The outside of the roof has mask-

ing tape cut into strips to simu-

late rolled roofing, and painted

medium gray.

33

MRH-Oct 2013